Plastic steel window hardware

A technology for hardware and plastic-steel windows, which is applied in door/window accessories, wing leaf parts, wing leaf suspension devices, etc., can solve the problem of opening angle less than 90 degrees, and achieve the effect of improving adaptability and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

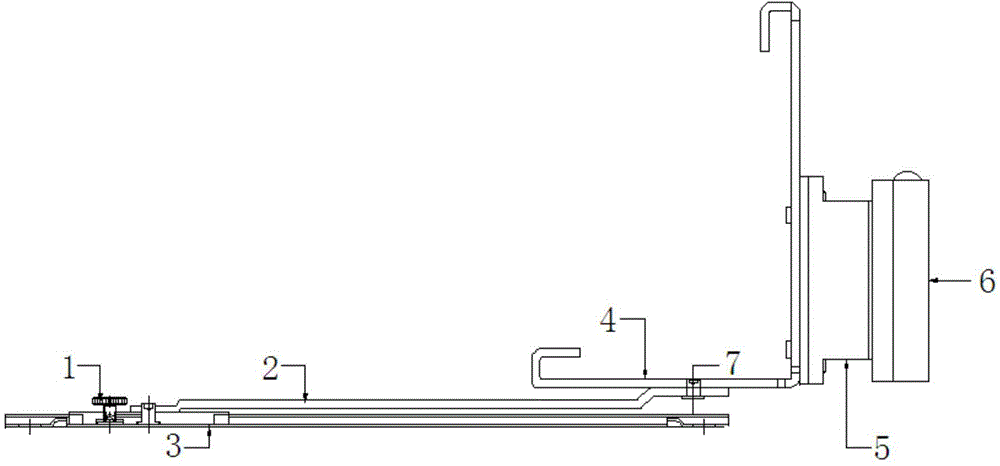

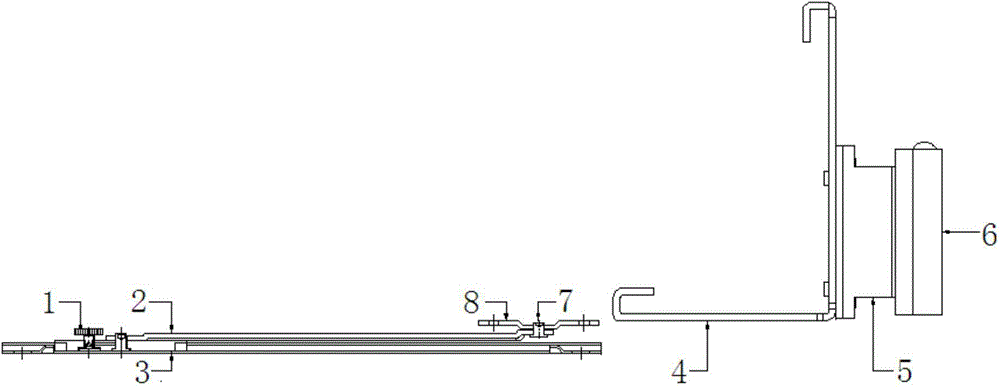

[0012] The present invention is described in more detail according to accompanying drawing now, as figure 1 As shown, a plastic-steel window hardware includes a wind brace and a corner hinge. The wind brace includes a slide bar 2 and a slide bar base 3. The rod 2 is located above the base of the sliding rod 3, and the other end of the sliding rod 2 is first bent upwards and then horizontally bent, and the horizontal bending part of the other end and the horizontal connecting piece 4 of the corner hinge pass through the pivot pin 7 connected, and the horizontal connecting piece 4 of the corner hinge is located above the other end of the slide bar 2 , and the height of the upwardly bent part is greater than the length of the shaft pin 7 .

[0013] The other end of the slide bar is bent upwards to be vertical or oblique.

[0014] The horizontal connecting piece of the corner hinge is 1 / 3 to 2 / 3 away from the connecting point of the horizontal connecting piece and the vertical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com