Cellulose ester-based resin composition

一种酯系树脂、纤维素的技术,应用在纤维素酯系树脂组合物及及其成型体领域,达到阻燃性优异、色调与阻燃性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1~5

[0091] Cellulose ester-based resin compositions were prepared by compounding as shown in Table 1 and Table 2 below, and kneaded under the following processing test conditions to test processability and process coloring resistance. The torque at the time of kneading was measured for processability, and the process coloring resistance was evaluated as follows.

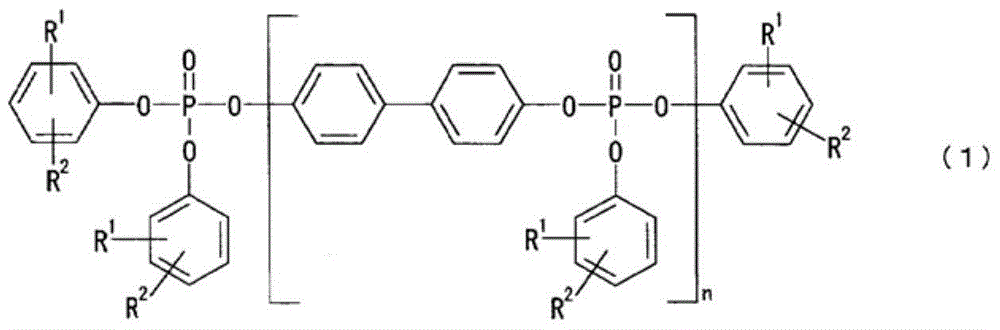

[0092] As the phosphoric acid ester represented by the above-mentioned general formula (1), the following phosphoric acid ester compound-1 was used. Phosphate ester compound-1 is a mixture of compounds with different n values.

[0093] Phosphate compound-1

[0094]

[0095] (In the formula, n represents a number from 1 to 5.)

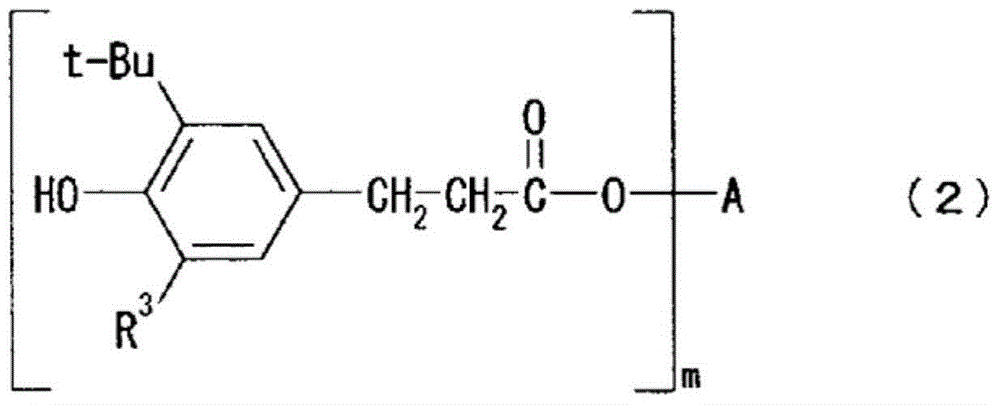

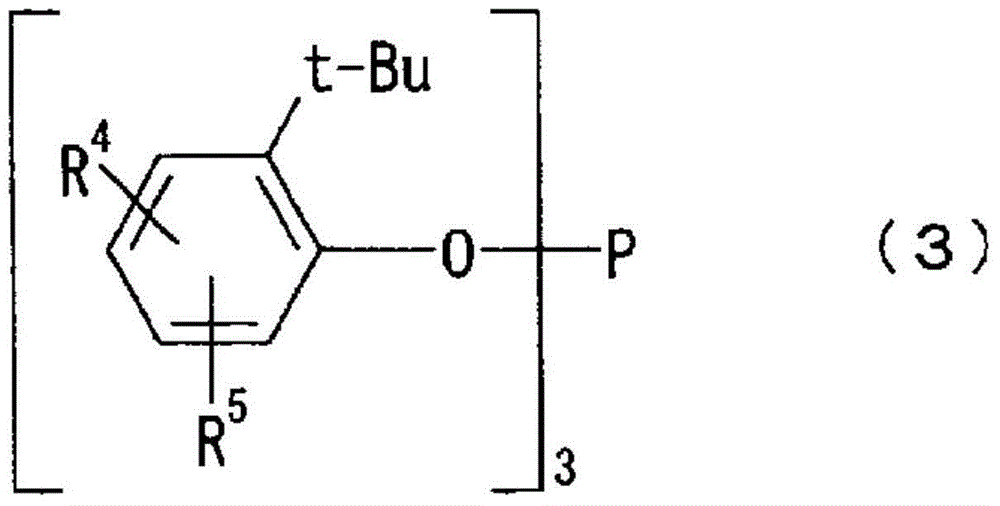

[0096] In addition, the following phenol compound-1 was used as the phenol compound represented by the above general formula (2), the following triaryl phosphite compound-1 was used as the triaryl phosphite compound represented by the above general formula (3), and the following The diaryl p...

Embodiment 4~9

[0130] The cellulose ester resin composition was prepared by compounding as shown in the following Table 3, extruded under the following processing conditions to produce pellets, and the pellets were used for injection molding at 240° C. to obtain a cellulose ester resin composition of 1.6 mm×12.7 mm×127 mm The test piece for the flame retardancy test was subjected to a flame retardancy UL-94V test according to the following test method.

[0131]

[0132] Machine: TEX28V (product made in THE JAPAN STEEL WORKS, LTD.)

[0133] Processing temperature: 230~240℃

[0134]

[0135] A test piece with a length of 127 mm, a width of 12.7 mm, and a thickness of 1.6 mm was kept vertical, and the flame was removed after the lower end was in contact with the flame of the burner for 10 seconds, and the time until the ignition of the test piece disappeared was measured. Next, the flame disappeared for the second time for 10 seconds, and the time until the ignition disappeared was measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com