Multi-edge bending machine

A bending machine, multilateral technology, applied in the field of bending machines, can solve the problems of complicated adjustment, waste of time, inconvenient operation, etc., and achieve the effect of increasing stability and accurate power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment of the present invention will be further described below in conjunction with the accompanying drawings, so as to help understand the content of the present invention.

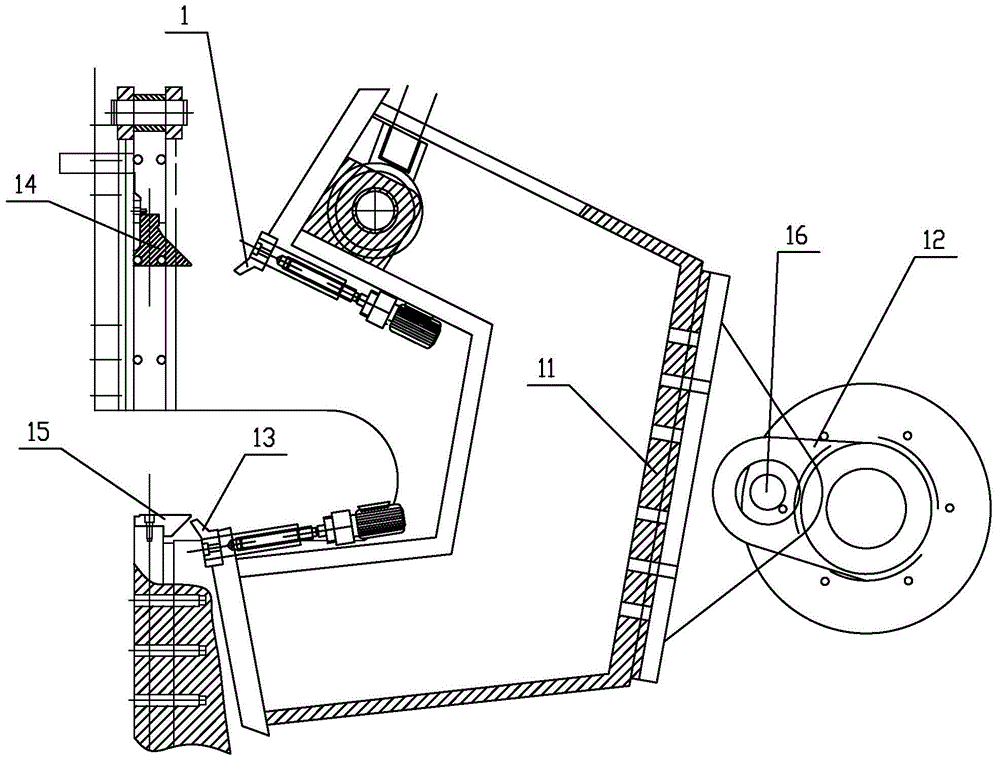

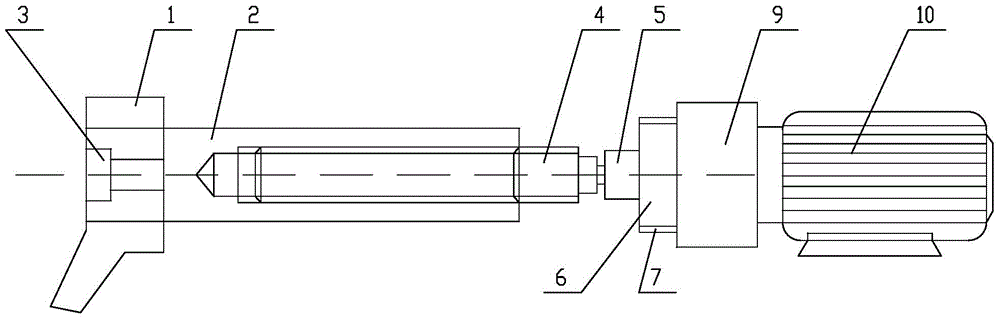

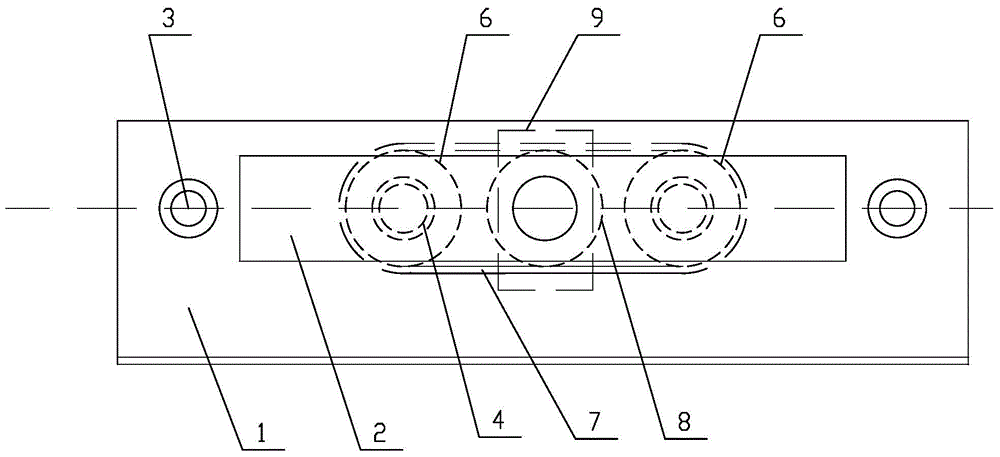

[0020] Such as Figure 1 to Figure 3 As shown, the present invention includes a knife rest 11 that is integrally shaped as a "concave", and the legs on both sides of the knife rest 11 are slightly opened outwards. The first upper mold 1 is arranged at the apex of the inner side of the leg, and the first lower mold 13 is arranged at the apex of the inner side of the lower leg of the knife rest 11, and the mold and the knife rest 11 are connected by bolts 3; the first upper mold 1 and the first lower mold 13 A rectangular through hole is arranged in the middle, and a rectangular push block 2 matched with it is arranged in the through hole. The left end face of the push block 2 does not exceed the left end face of the mould; A rectangular through hole matched with the push block 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com