Horizontal well self-guide hydraulic water jetting device and method

A hydraulic jet and self-guiding technology, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve the problems of small rotational torque, inaccurate perforation direction, and difficult operation, and achieve high orientation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

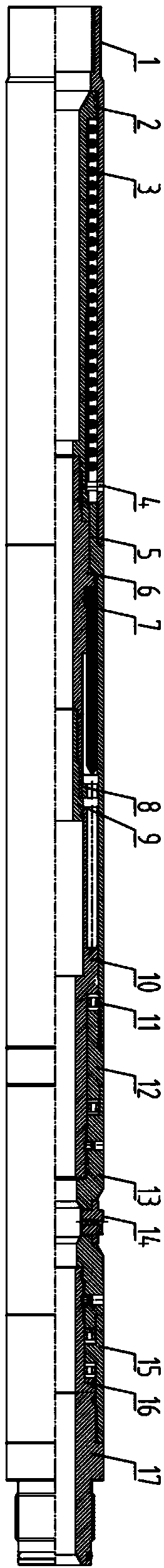

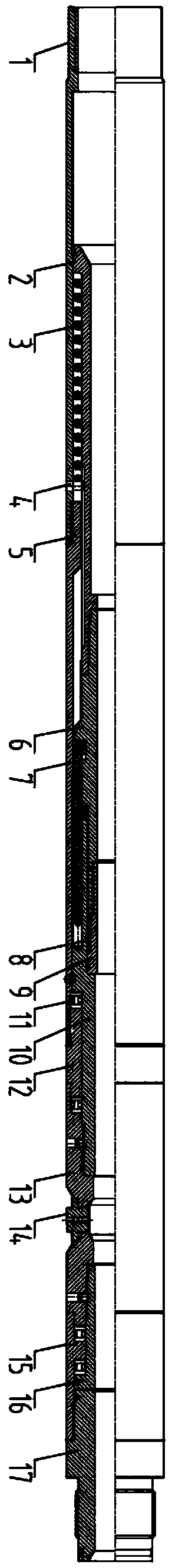

[0036] see figure 1 and 2 , shows the horizontal well self-guiding hydraulic water injection device of the present invention.

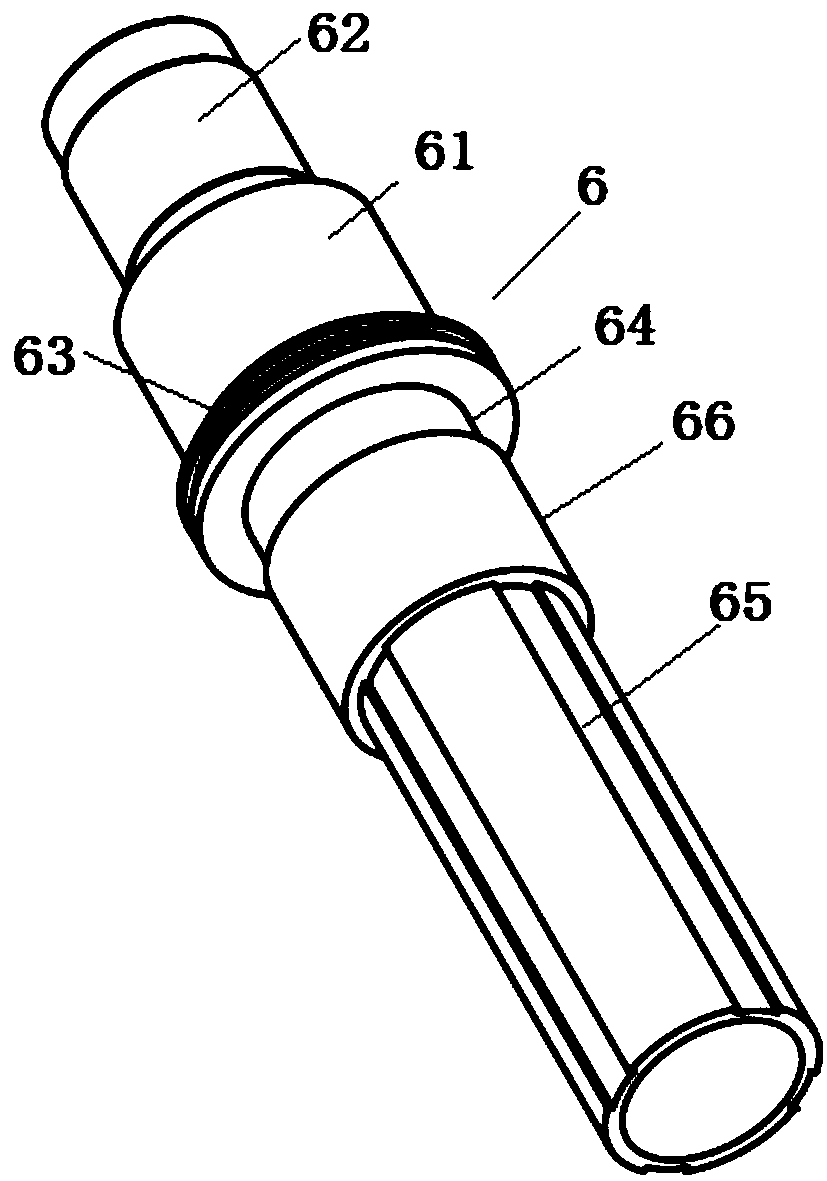

[0037] The horizontal well self-guiding hydraulic water injection device may include an upper joint 1, a liquid cylinder 2, a return spring 3, an orientation screw 4, a connecting sleeve 5, a push rod 6, a gravity rod 7, a direction control ring 8, a limit joint 9, The rotating ring 10, the spray gun assembly and the lower joint 17, wherein the upper joint 1 and the lower joint 17 are respectively arranged at two ends, and the upper joint 1 is provided with a liquid cylinder 2 which can slide back and forth and cannot be rotated. An annular space is formed between the cylinder 2 and the upper joint 1 to accommodate the return spring 3 , and the rear end of the return spring 3 abuts against the annular projection of the hydraulic cylinder 2 to provide the restoring force of the hydraulic cylinder 2 .

[0038] Wherein, in order to realize the non-rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com