Power cable recovery device

一种回收装置、电力线缆的技术,应用在电力线缆回收装置领域,能够解决加速线缆老化、安全隐患、增加重量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

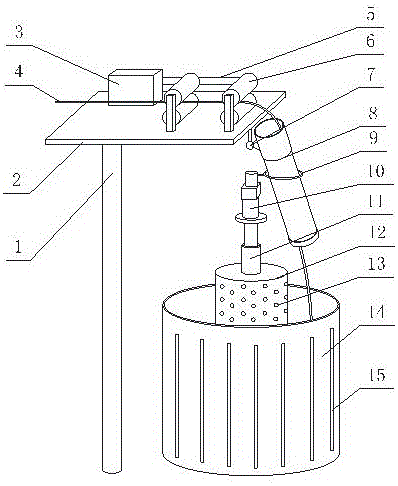

[0019] Example: see figure 1 , a power cable recovery device, including a frame 1 and a mounting plate 2 arranged on the frame 1, and also includes a driving wheel 6 for pulling the cable 4 and a guide cylinder 8 for guiding the cable 4, and also includes an alignment The winding basket 14 for storing the cable 4 is provided with a drying and dust-removing cleaning device 12 in the middle of the winding basket 14; The outside of the cylinder 8 drives the orbiting ring 9 whose bottom end orbits on the horizontal plane, and the orbiting ring 9 is controlled by a rotating device and a lifting device.

[0020] As preferably, described driving wheel 6 is two groups and is arranged side by side on mounting plate 2, and mounting plate 2 is also provided with the driving motor 3 that provides power, and driving motor 3 drives driving wheel to rotate through conveyor belt 5, and each group of driving wheel is Cooperate with the upper and lower wheels provided, and the cable 4 passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com