A Machining Method of Radial Narrow Groove in Annular Case

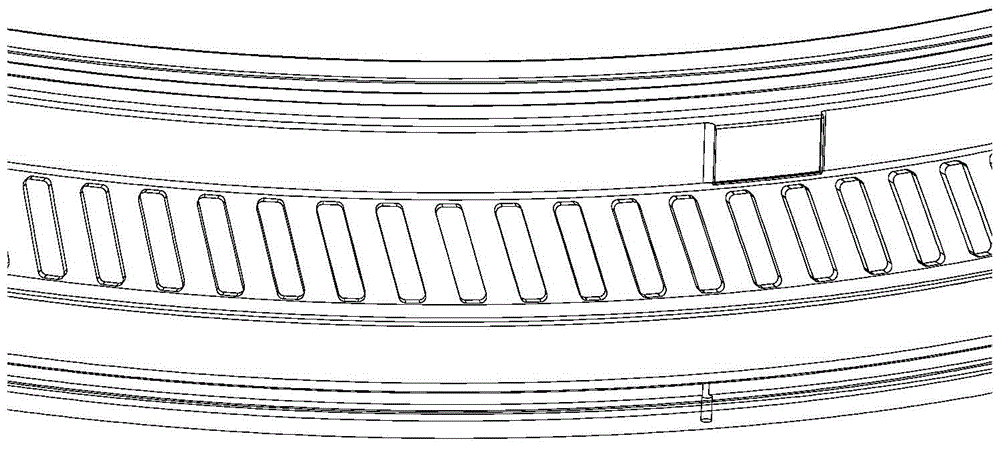

A processing method and narrow groove technology, applied in metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve the problems of low quality and low processing efficiency of radial narrow grooves in annular casings, so as to improve quality and speed up The effect of development progress, efficiency improvement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] The existing technology requires pre-drilling, rough grooving, fine milling and other processing processes. During this process, the strokes of the empty tool are more, and the processing efficiency is low; During the processing process, the high-efficiency processing state of small depth of cut and large feed is always maintained, thereby improving the processing efficiency of parts, reducing the time of human intervention, and ensuring the processing dimensional accuracy.

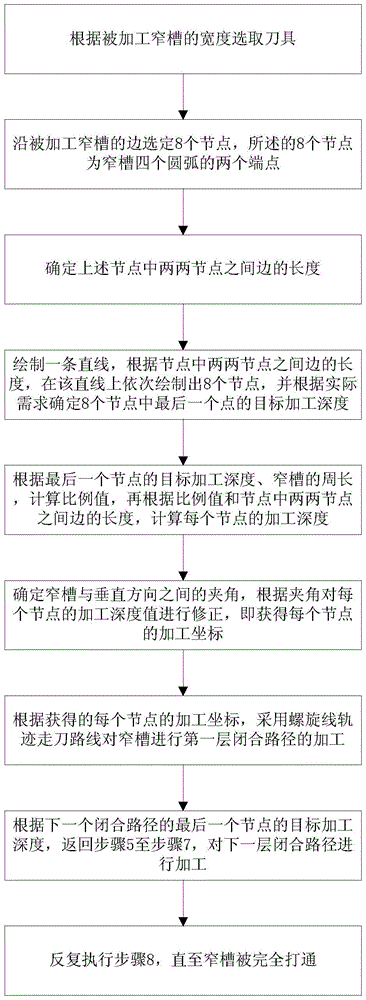

[0027] In the embodiment of the present invention, the processing method of the radial narrow groove of the annular casing, the method flow chart is as follows figure 1 shown, including the following steps:

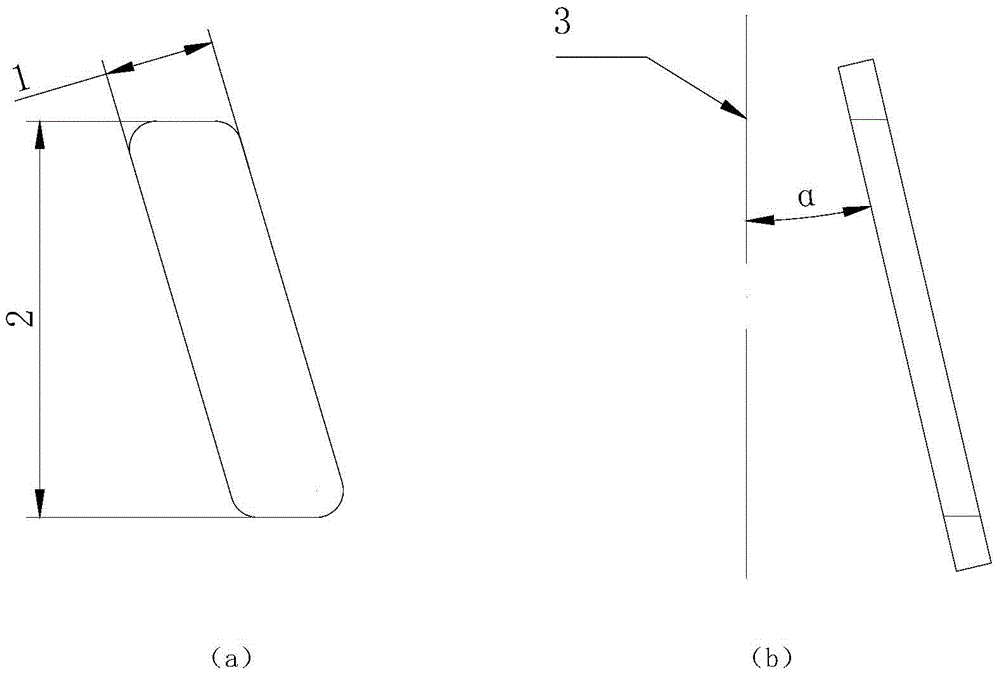

[0028] Step 1. Select the tool according to the width of the narrow groove to be processed, and the diameter of the selected tool is larger than the width of the narr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com