Milling machine flying cutter with adjustable tool geometric angle and milling machine

A milling machine and tool technology, applied in milling machine equipment, milling cutters, manufacturing tools, etc., can solve the problems of inability to adjust the geometric angle of the tool at the same time, reduce the versatility, and make it difficult to give full play to the cutting performance of the tool, so as to improve the processing efficiency and improve the general performance, and the effect of expanding the processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

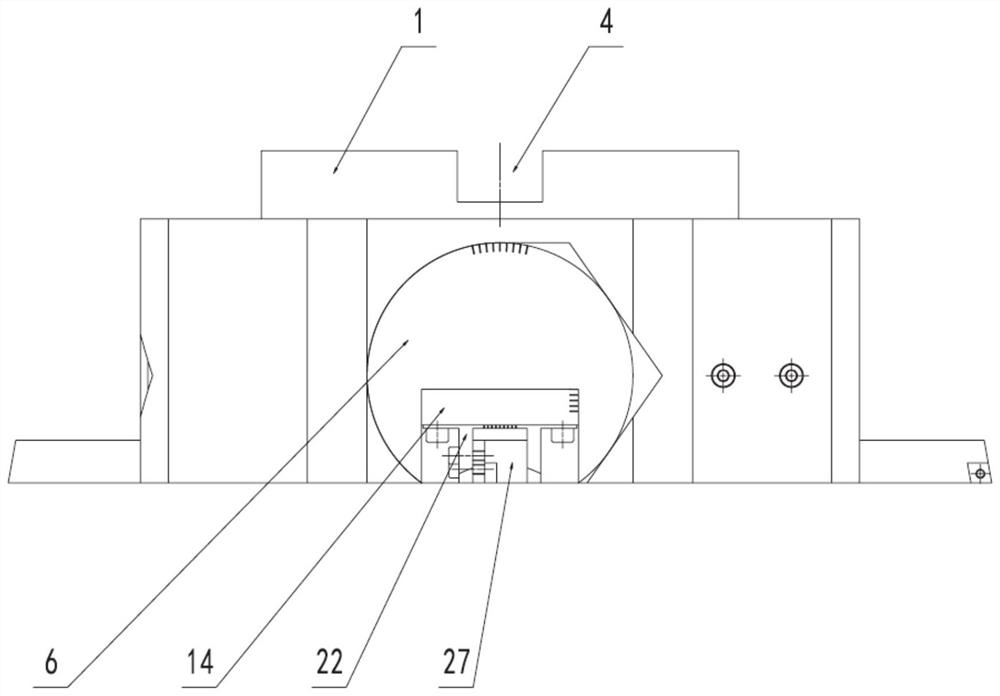

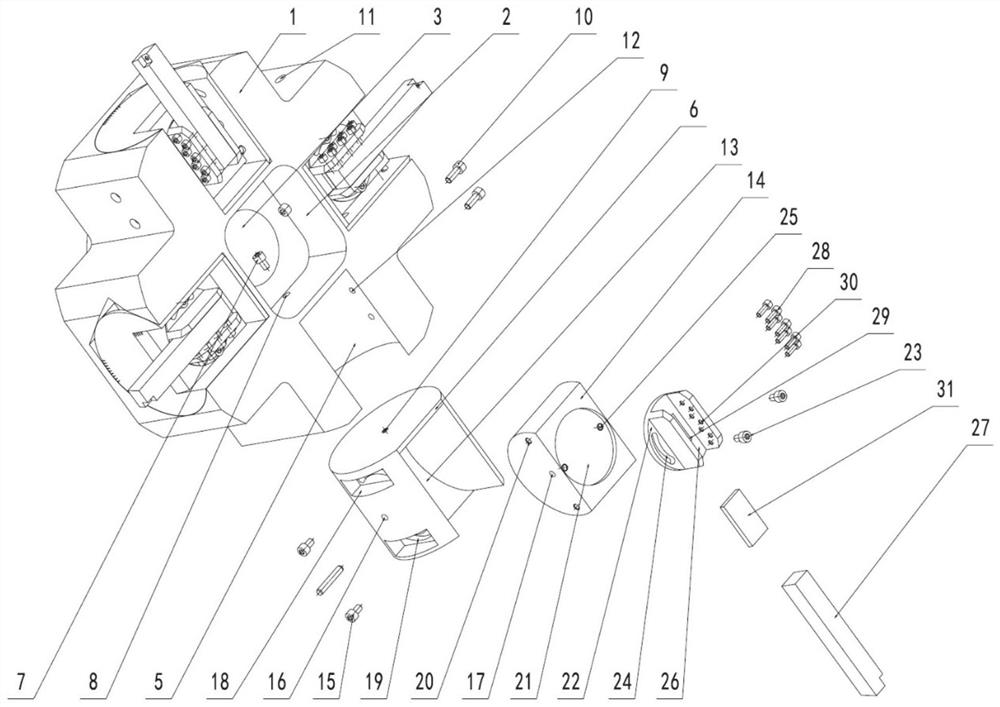

[0035] This embodiment provides a milling machine flying cutter with adjustable cutter geometry angle, such as figure 1 and figure 2 As shown in the figure, it includes a flying cutter head body 1, an adjustment assembly and a cutter bar 27. The flying cutter head body 1 is evenly spaced circumferentially to install a plurality of adjustment assemblies, and the cutter bar 27 is connected with the adjustment assembly. Angle, clearance angle, main declination angle, secondary declination angle and edge inclination angle adjustment, and can adapt to different sizes and specifications of the arbor 27.

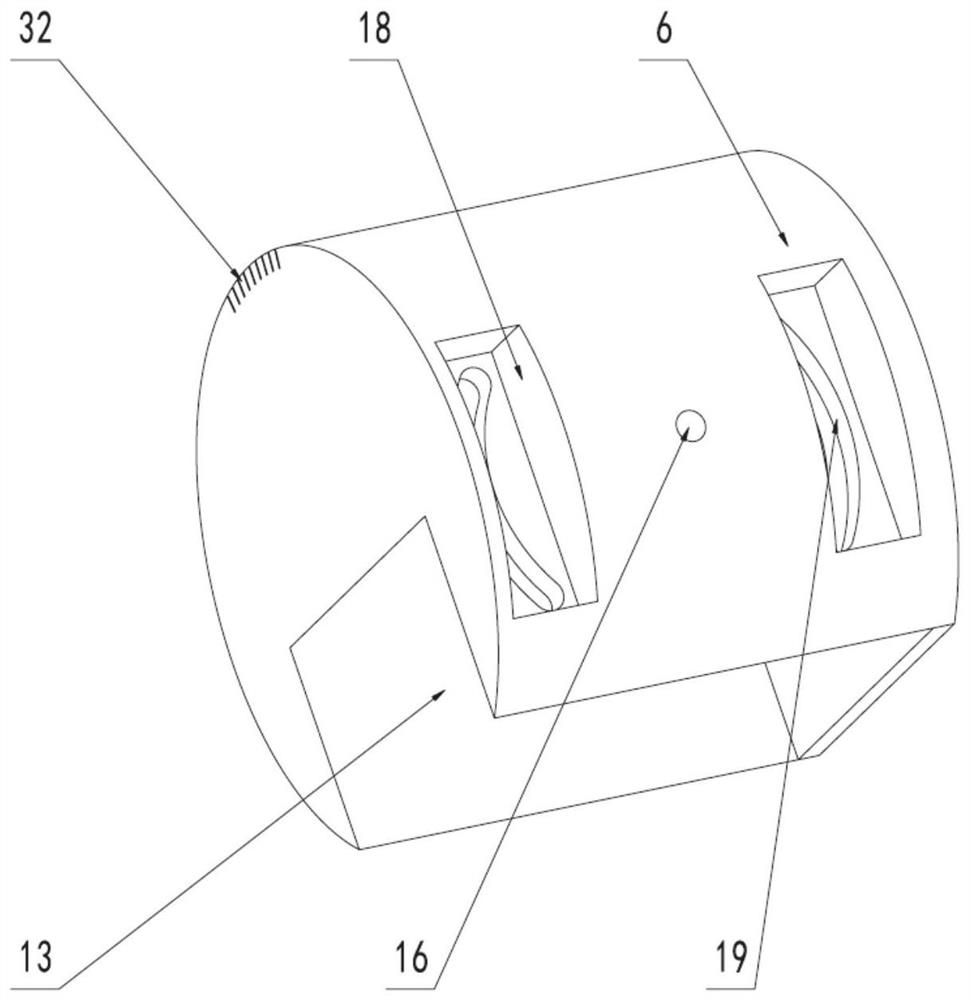

[0036] Further, the adjustment assembly includes front and rear angle adjustment blocks 6, main and auxiliary declination angle adjustment blocks 14, and edge inclination angle adjustment blocks 22. The block 6 is connected with the flying cutter disc body 1 .

[0037] Specifically, the bottom end face of the flying cutter head body 1 (with the orientation of the flying cutter a...

Embodiment 2

[0060] This embodiment provides a milling machine, including the milling machine flying cutter described in Embodiment 1, and the milling machine flying cutter is connected to the milling machine spindle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com