Multi-stage screw spring transmission

A transmission and spring clutch technology, which is applied in the field of transmission technology and gear transmission, can solve the problems of high efficiency, low transmission clutch efficiency, and impractical transmission efficiency, and achieve the effect of simplification of clutch action and easy shifting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

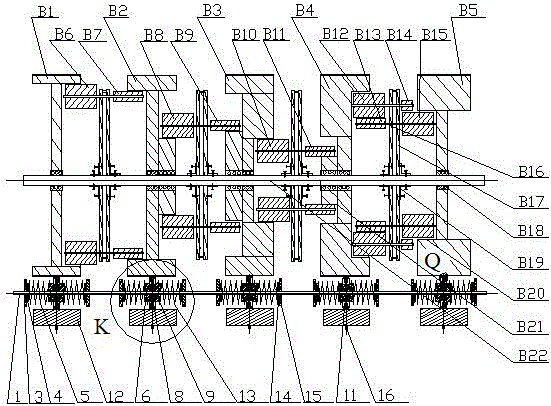

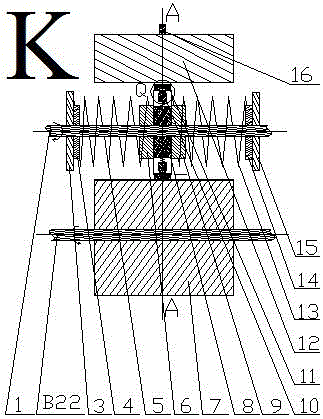

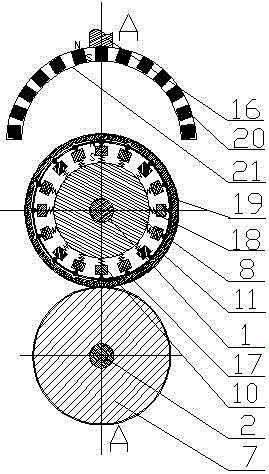

[0019] exist figure 1 In the embodiment shown in -7: the multi-stage screw spring transmission includes a set of coaxial and co-cylindrical multi-stage forward and reverse transmission devices, and multiple sets of screw spring clutches; it is characterized in that: coaxial and co-cylindrical multi-stage positive The reverse transmission device includes a plurality of driven wheels, from left to right are the first-stage driven wheel B1, the second-stage driven wheel B2, the third-stage driven wheel B3, the fourth-stage driven wheel B4 and the fifth-stage driven wheel B5. They are all connected by bearings B18 and installed on the same fixed shaft B22, and the axis lines of the driven wheels at all levels overlap with the axis lines of the fixed shaft B22, and the driven wheels at all levels can rotate on the fixed shaft B22 without driving the fixed shaft B22 Rotating, coaxial and cylindrical multi-stage positive and negative transmission devices have a set of power input pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com