Engine high pressure turbine blade surface temperature measuring device

A technology of measuring device and high-pressure turbine, applied in measuring device, thermometer, measuring heat, etc., can solve the problems of unbearable measuring means, high temperature of turbine blades of aero-engine, large error, etc., to avoid heat accumulation and improve production efficiency , to avoid the effect of repeated driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

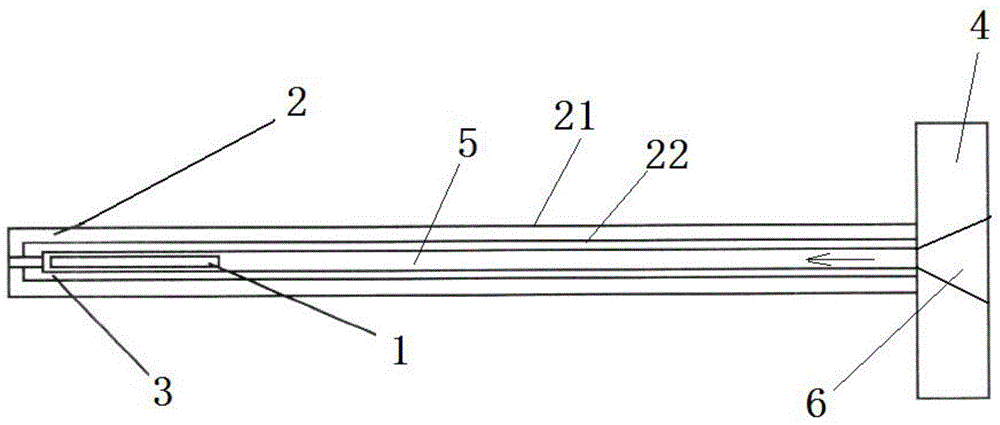

[0014] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 , figure 2 As shown, the present invention includes a mounting flange 4, and the measuring device is installed on the casing in front of the engine turbine through the mounting flange 4; the mounting flange 4 fixes the "U" type liquid cooling device 2, and the "U" type A "U"-shaped gas cooling device 3 is arranged in the liquid cooling device 2, and a through hole 5 is arranged in the "U"-shaped gas cooling device 3, and a photoelectric probe 1 is arranged in the through hole 5;

[0015] In order to further cool the photoelectric probe 1 and prevent heat accumulation in the through hole 5, the mounting flange 4 is provided with a bell mouth 6, and the bell mouth 6 is connected to the through hole 5;

[0016] The wall thickness of the outer side 21 of the liquid cooling device 2 is greater than that of the inner side 22;

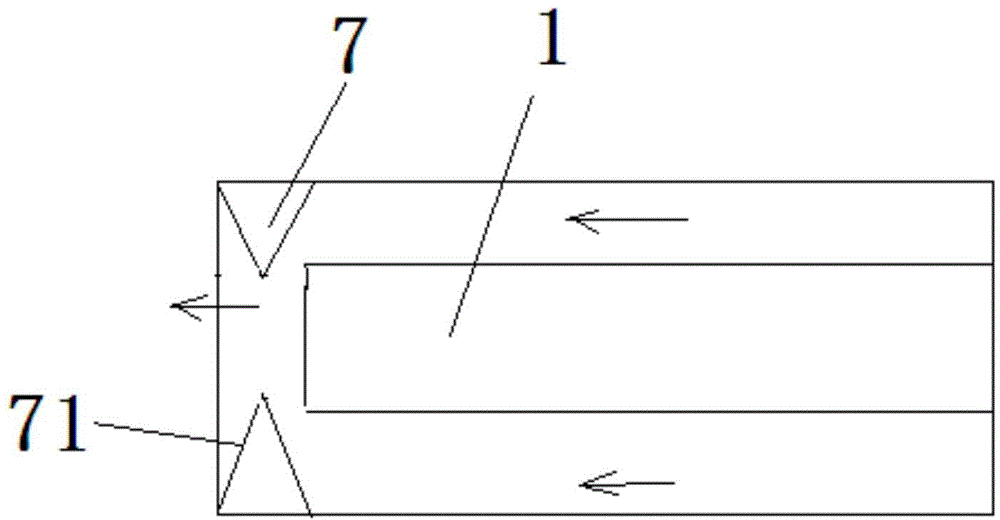

[0017] In order to prevent the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com