Coal dry-distillation device and modified coal production equipment using same

A technology for manufacturing equipment and coal dry distillation, which is applied in the fields of coal dry distillation devices and upgraded coal manufacturing equipment, can solve problems such as temperature reduction, and achieve the effect of inhibiting the increase of mercury concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

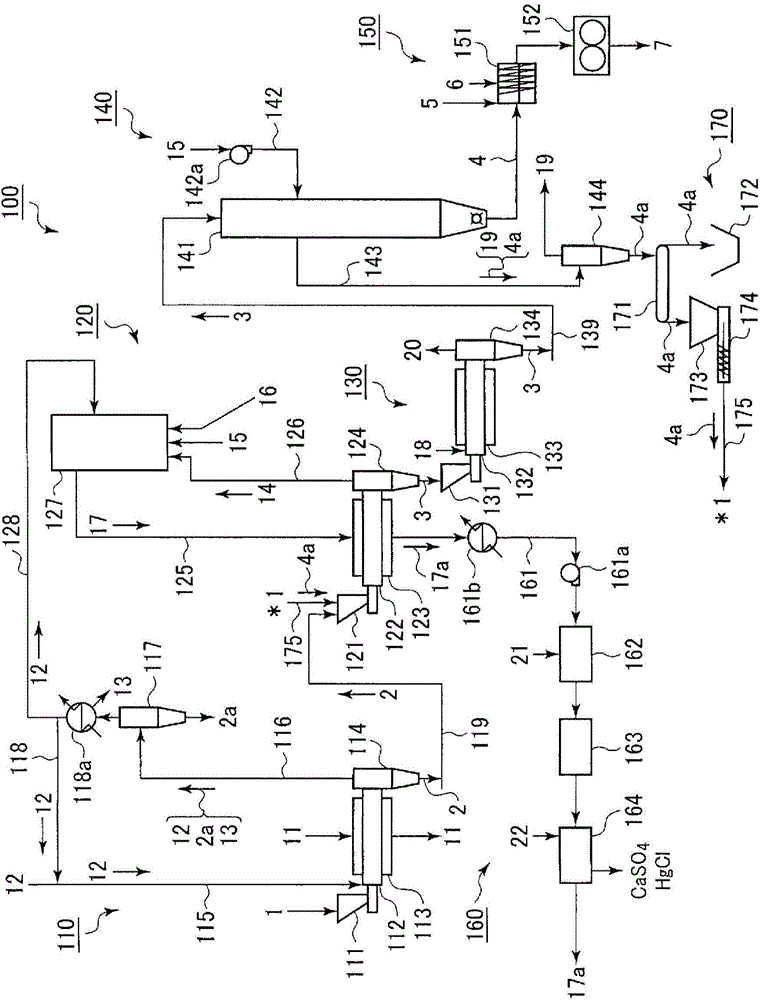

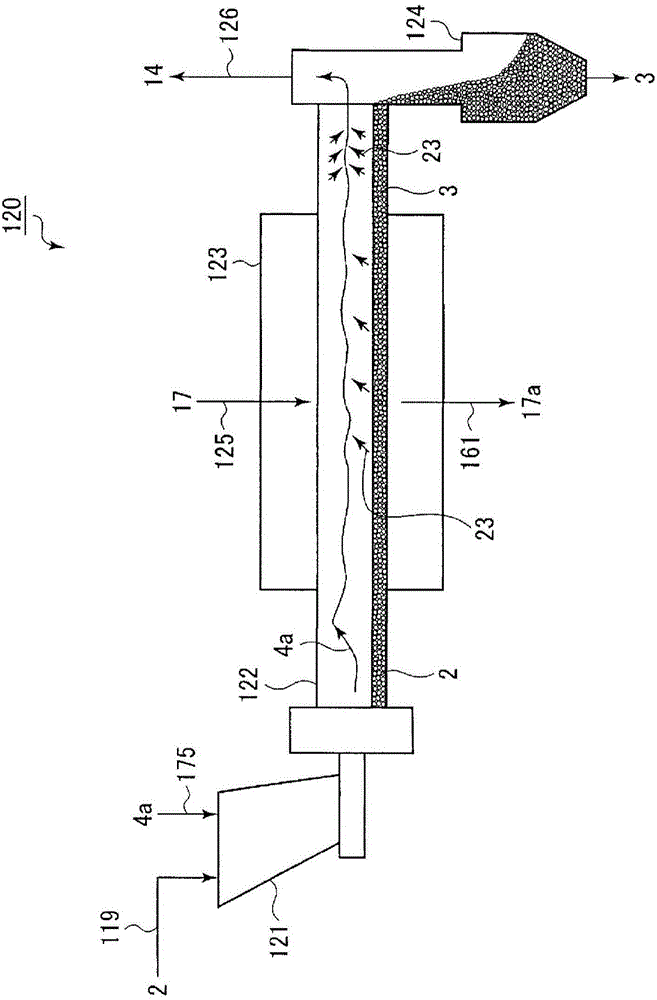

[0037] in accordance with figure 1 , 2 A first embodiment of the coal pyrolysis device and the upgraded coal production facility using the coal pyrolysis device of the present invention will be described.

[0038] Such as figure 1 As shown, the coal drying mechanism, that is, the coal drying device 110 that dries coal with high moisture content, such as lignite and sub-bituminous coal, that is, low-rank coal (inferior coal) 1 includes: a hopper 111 that receives the low-rank coal 1; cylinder (body trunk) 112, which is rotatably supported, and supplies the low-rank coal 1 in the funnel 111 from one end side (base end side) to the inside; an outer cylinder (skin) 113, which is The inner cylinder 112 is rotatable and fixedly supported by covering the outer peripheral surface of the inner cylinder 112, and the heating medium, namely steam 11, is supplied to the inner side (between the inner cylinder 111); The cylinder 112 is rotatably connected to the other end side (front end ...

no. 2 approach

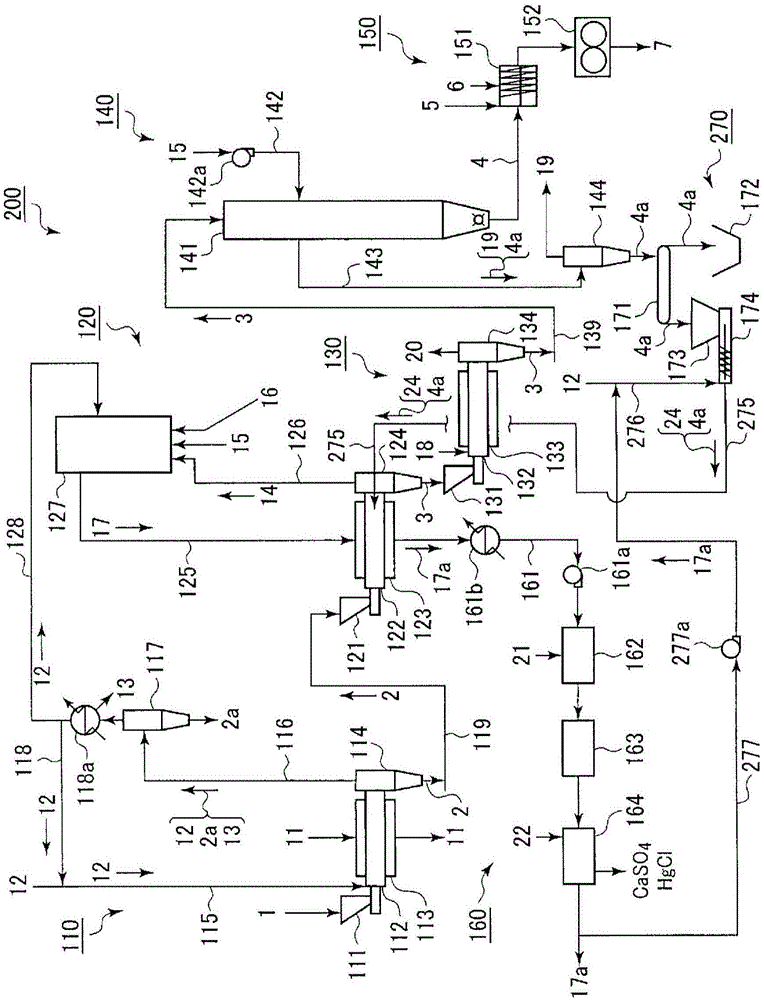

[0089] in accordance with image 3 , 4 A second embodiment of the coal pyrolysis device according to the present invention and the upgraded coal production facility using the coal pyrolysis device will be described. In addition, the same symbols as those used in the description of the above-mentioned embodiment will be used for the same parts as those in the above-mentioned embodiment, and the description that overlaps with the description in the above-mentioned embodiment will be omitted.

[0090] Such as image 3 As shown, one end side (base end side) of a pulverized coal feeding pipe 275 is connected to the front end side of the feeding device 174 . A protective gas supply line 276 for supplying an inert gas 12 such as nitrogen is connected to a connection portion between the front end side of the feeder 174 and the pulverized coal supply pipe 275 . In addition, the gas sending part of the desulfurization device 164 is connected to the outside of the system, and at the s...

no. 3 approach

[0099] in accordance with Figure 5 A third embodiment of the coal pyrolysis device according to the present invention and the upgraded coal production facility using the coal pyrolysis device will be described. In addition, the same symbols as those used in the description of the above-mentioned embodiment will be used for the same parts as those in the above-mentioned embodiment, and the description that overlaps with the description in the above-mentioned embodiment will be omitted.

[0100] Such as Figure 5 As shown, a pyrolysis coal distributing line 371 for dispensing a part of the pyrolysis coal 3 conveyed by the pyrolysis coal conveying line 139 is connected in the middle of the pyrolysis coal conveying line 139 . The dry distillation coal subpackaging line 371 is connected to a dry distillation coal conveying device 372 , and the dry distillation coal conveying device 372 is used to transport the dry distillation coal 3 packaged by the dry distillation coal subpacka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com