General gasoline engine

A general-purpose gasoline engine and general-purpose engine technology, which is applied to cylinders, cylinder heads, mechanical equipment, etc., can solve problems such as the lack of cooperation between the shroud and the fan cover, the impact of the airtightness of the cooling space, and the impact on the heat dissipation effect, etc., to achieve easy disassembly and installation and maintenance, easy operation, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

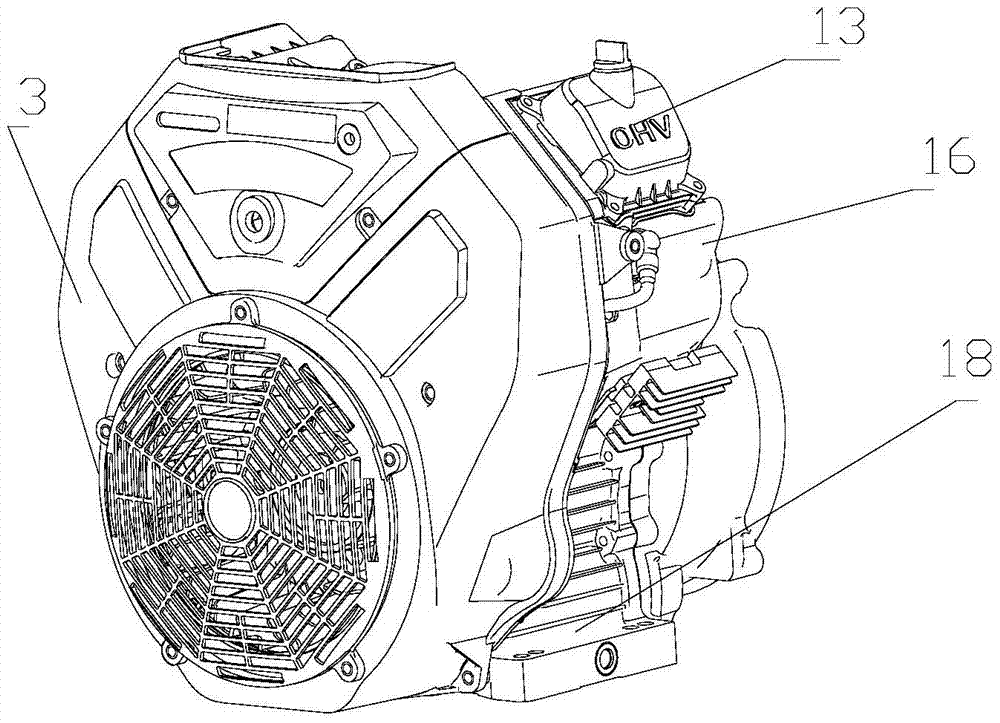

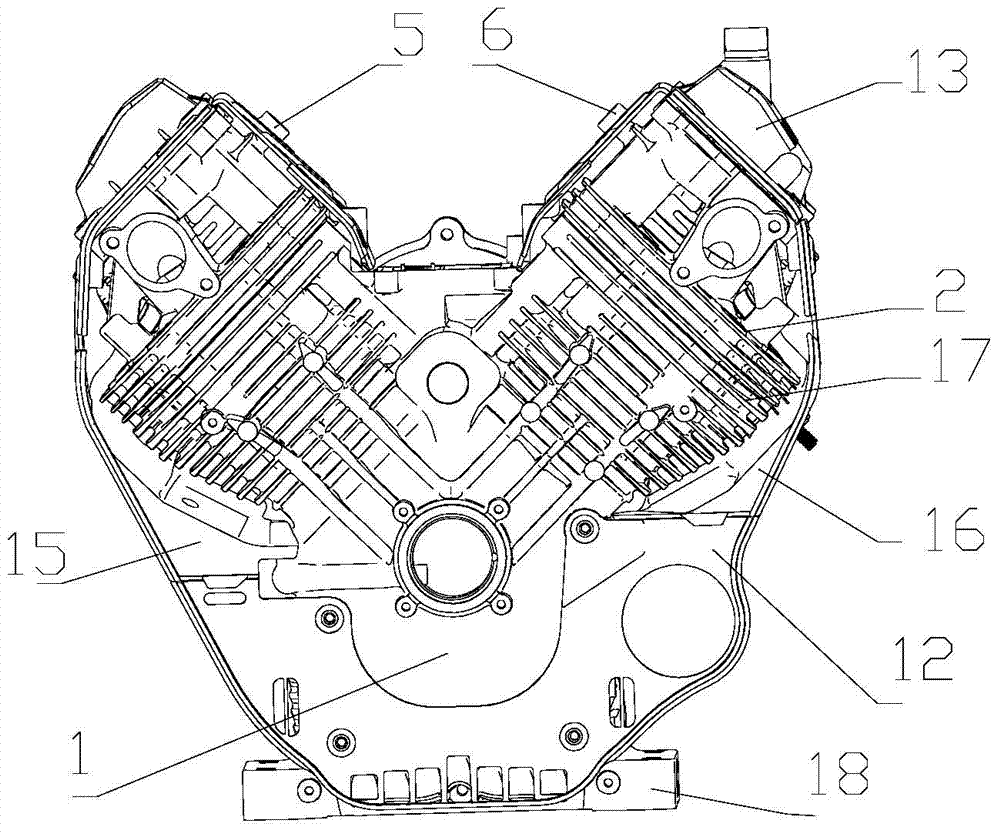

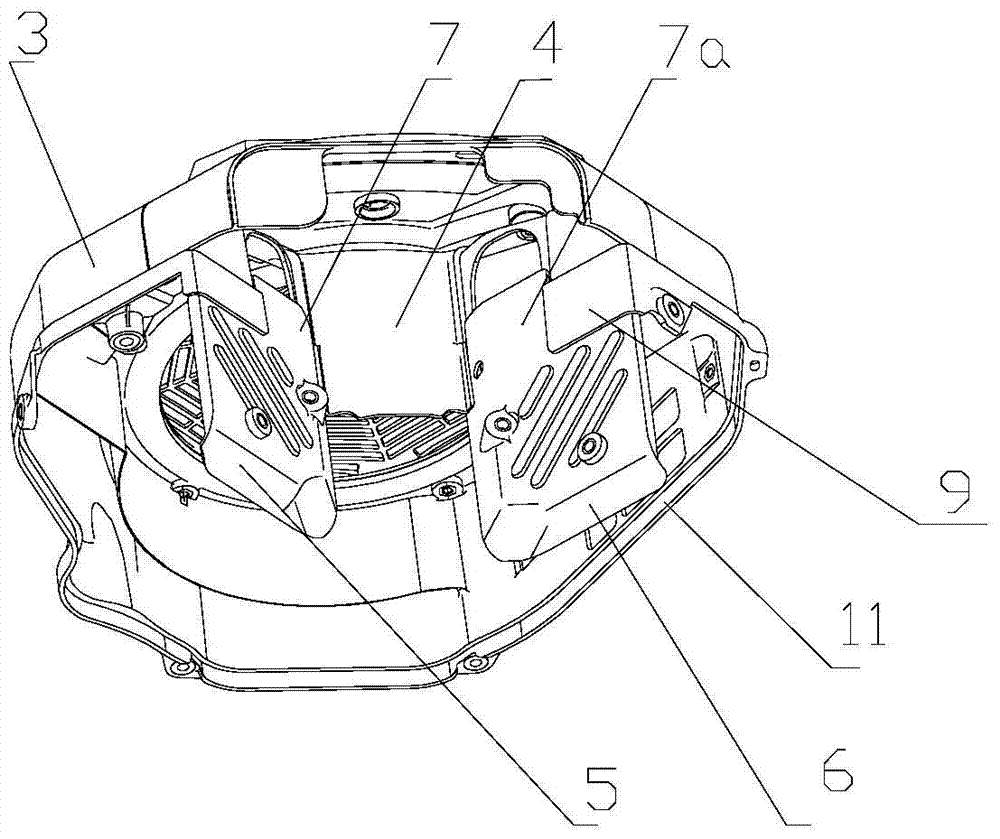

[0025] As shown in the figure: the general-purpose gasoline engine of the present invention includes a general machine casing 1 and a two-way engine cylinder head 2 connected with the general machine casing 1, and an upper air passage assembly that forms an upper cooling air passage at the periphery of the general machine cylinder head 2, so The upper air duct assembly includes a fan cover 3 and a shroud, and the shroud and the fan shroud 3 are plugged together to form a cooling air duct through which cooling air flows between the cylinder heads 2 of the two-way machine; the present invention The structure is suitable for forced air-cooled fans, wherein the fan cover 3 is used to cover the impeller, and the fan cover 3 and the wind guide cover assembly are used to form an upper cooling air passage for cooling the cylinder head 2 of the fan. In this embodiment, The plug-in cooperation between the shroud and the fan cover 3 makes the cooperation between the various parts more clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com