A switch using a torsion spring as a terminal

A technology of torsion springs and terminals, which is applied in the field of electronic switches, can solve the problems affecting the feel and life of keys, and the insufficient strength of metal sheets, etc., and achieve the effects of good application prospects, good feel, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

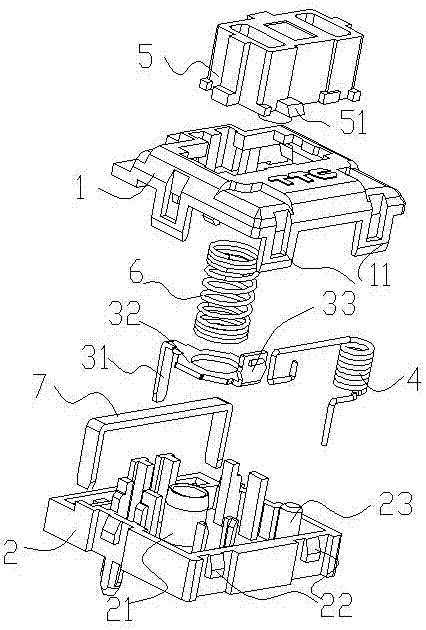

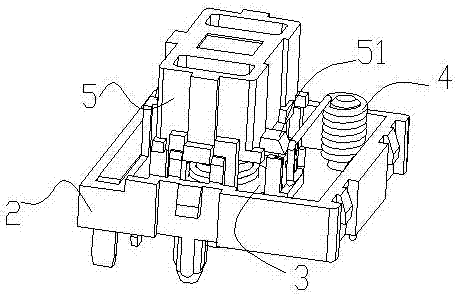

[0027] figure 1 It is the overall structure explosion diagram of embodiment 1, such as figure 1 As shown, the switch using a torsion spring as a terminal according to the present invention includes an upper cover 1, a base 2, a pressing member 5, a return spring 6, a movable terminal 4 and a fixed terminal 3, and a plurality of buttonholes are arranged on the periphery of the upper cover 1 11, and the place where the base 2 corresponds to the button hole 11 of the upper cover 1 is provided with a card position 22, and the upper cover 1 and the base 2 can be fastened through the cooperation of the button hole 11 and the card position 22. After the buckle, the upper cover 1 and the A cavity is formed in the middle of the base 2 for placing the pressing member 5 , the return spring 6 , the movable terminal 4 and the fixed terminal 3 . The base 2 is provided with a guide post 21 , the lower part of the guide post 21 extends out of the bottom of the base 2 , the return spring 6 is...

Embodiment 2

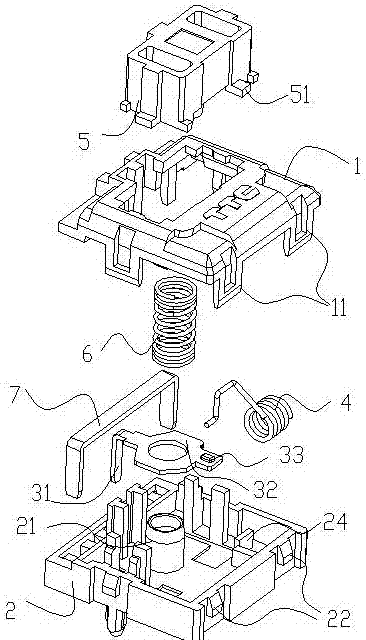

[0032] Figure 4 It is the overall structure explosion diagram of embodiment 2, as Figure 4 As shown, embodiment 2 is the same as embodiment 1, including upper cover 1, base 2, pressing member 5, return spring 6, movable terminal 4 and fixed terminal 3, and the left and right ends of the upper cover 1 are respectively provided with a button hole 11. At the same time, there are two button holes 11 in the lower part, and the base 2 is provided with a card position 22 corresponding to the button holes 11 of the upper cover 1. The upper cover 1 and the base 2 can cooperate with the button holes 11 and the card positions 22. After fastening, a cavity is formed between the upper cover 1 and the base 2 for placing the pressing member 5 , the return spring 6 , the movable terminal 4 and the fixed terminal 3 . The base 2 is provided with a guide post 21, one end of the guide post 21 is fixed on the base 2, and the other end is connected and fixed to the lower part of the pressing mem...

Embodiment 3

[0037] Figure 7 It is the overall structure explosion diagram of embodiment 3, as Figure 7 As shown, the embodiment 3 is the same as the embodiment 2, including the upper cover 1, the base 2, the pressing member 5, the return spring 6, the movable terminal 4 and the fixed terminal 3, and the left and right ends of the upper cover 1 are respectively provided with a button hole 11. At the same time, there are two button holes 11 in the lower part, and the base 2 is provided with a card position 22 corresponding to the button holes 11 of the upper cover 1. The upper cover 1 and the base 2 can cooperate with the button holes 11 and the card positions 22. After fastening, a cavity is formed between the upper cover 1 and the base 2 for placing the pressing member 5 , the return spring 6 , the movable terminal 4 and the fixed terminal 3 . The base 2 is provided with a guide post 21, one end of the guide post 21 is fixed on the base 2, the other end is connected and fixed with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com