Toothed-plate connection structure of roller of crusher

A connection structure and crusher technology, applied in grain processing, etc., can solve problems such as high friction, inconvenient installation, and difficult disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

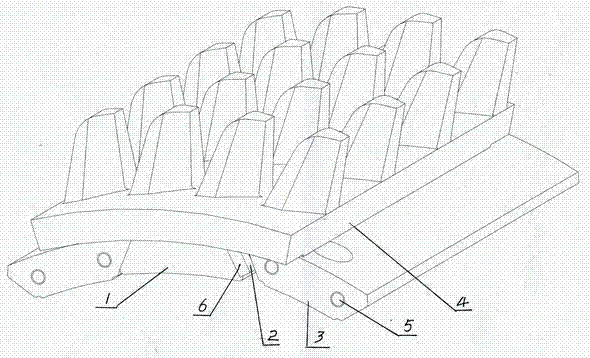

[0007] The embodiment is described in detail in conjunction with the accompanying drawings, which includes a roller crusher roller. The main improvement point is to change the dovetail groove substrate 3 on the roller from the same size at both ends to one side with an angle of 3-6 degrees from one end to the other end. the excessive slope; also change the dovetail chuck 1 at the bottom of the tooth plate to the slope corresponding to the transition slope on the base plate of the dovetail groove, and weld a fixed slope in the transition slope of the substrate, one side is a plane and the other side corresponds to the excessive slope Iron 2, an installation oblique iron 6 is reversely inserted between the contact surface between the fixed oblique iron and the dovetail chuck. Keep the arc-shaped pressing plate 4 and its fixing bolt 5 unchanged. Through the improvement of the dovetail groove between the base plates, the present invention makes the dovetail groove between the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com