A car tire loading and unloading rack

A technology of car tires and loading and unloading racks, which is applied to tire installation, wheel assembly and disassembly equipment, wheels, etc., which can solve the problems of laborious and dangerous loading and unloading of car tires, and achieve the effect of stable structure and convenient and quick tire loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

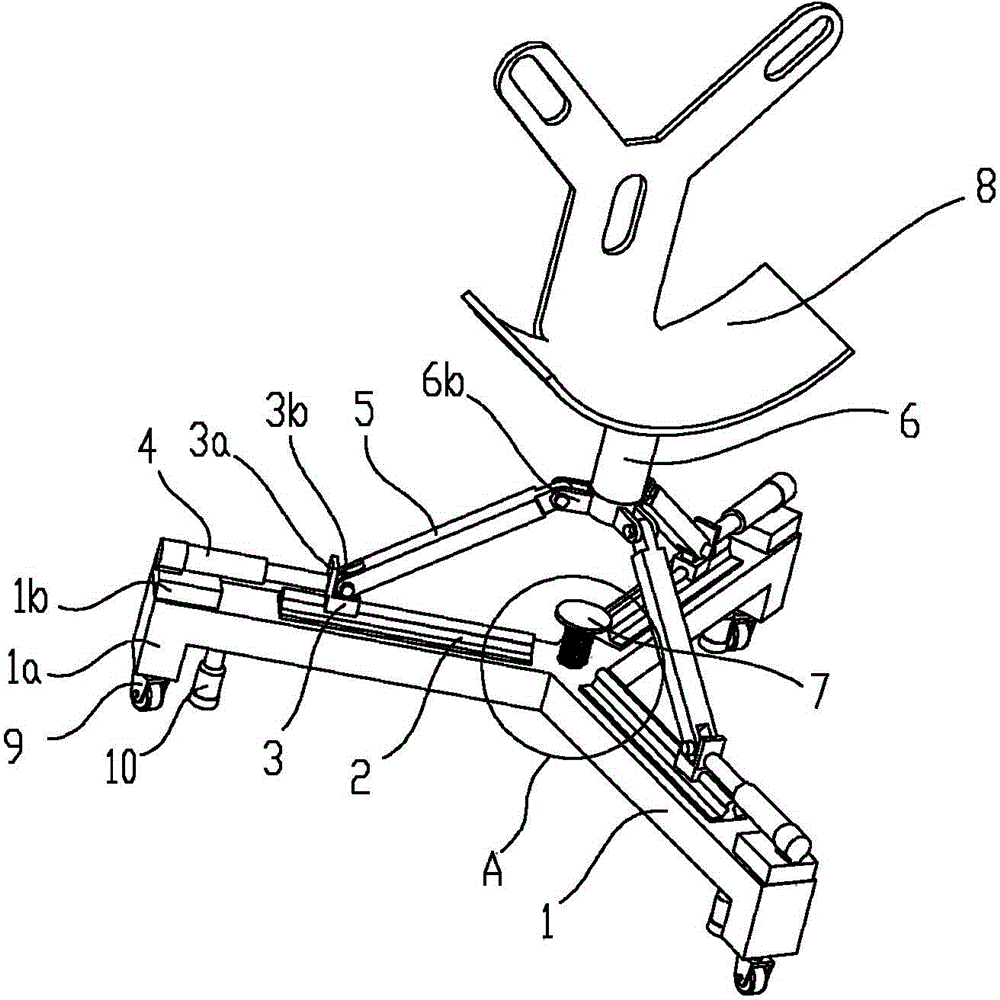

[0016] Such as figure 1 As shown, a kind of automobile tire loading and unloading rack provided by the present invention comprises a Y-shaped base 1 composed of three beams. 6 connected to the tire bracket 8, characterized in that:

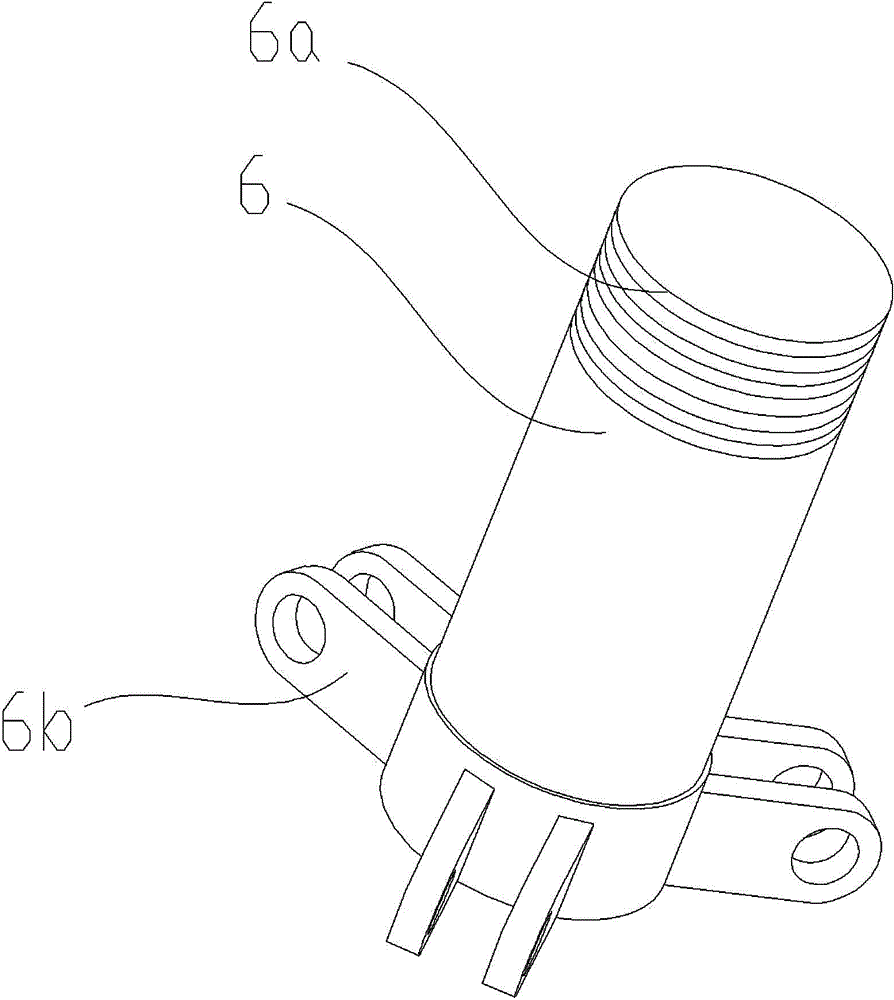

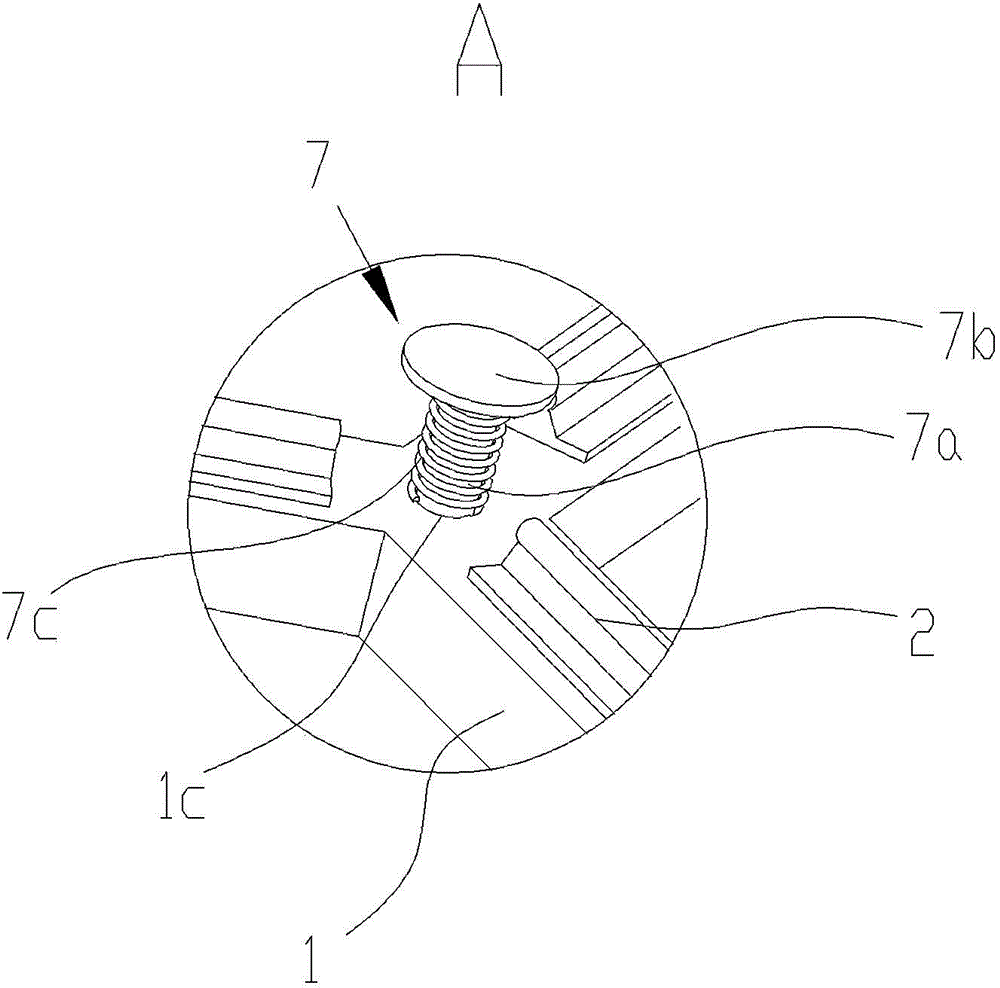

[0017] a. There is a through hole 1c in the middle of the Y-shaped base 1, a spacer 1b is connected above the end of each beam, and a leg 1a is arranged below, and a spacer 1b is connected to each spacer 1b. The jack 4 is connected to the wheel 9 on the support foot 1a, and the wheel 9 adopts a universal wheel, and a telescopic foot 10 is also connected to the bottom of the beam next to the foot 1a, and the telescopic foot 10 adopts a jack. The front side of the upper spacer 1b is matched with a slide rail 2, and a slide block 3 is arranged on the slide rail 2, and each slide block 3 is respectively connected with a vertical plate 3a and a hinge block 3b by bolts. The piston rod of the jack 4 is connected to the vertical plate 3a, and the hinge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com