Bow-like elastic contact spring

An elastic contact, bow-shaped technology, applied in contact parts, connections, parts of connecting devices, etc., can solve the problems of easy fatigue damage of reed contacts, and achieve easy fatigue damage, disperse bending stress, and reduce fatigue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

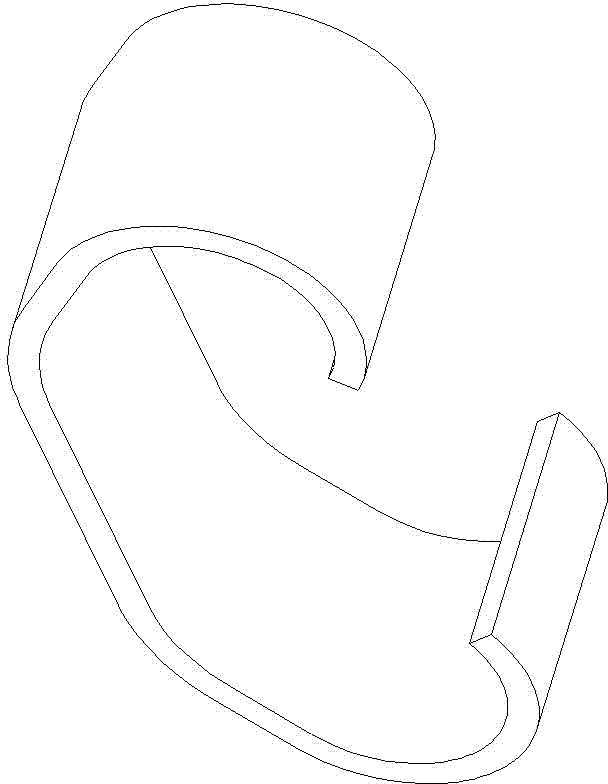

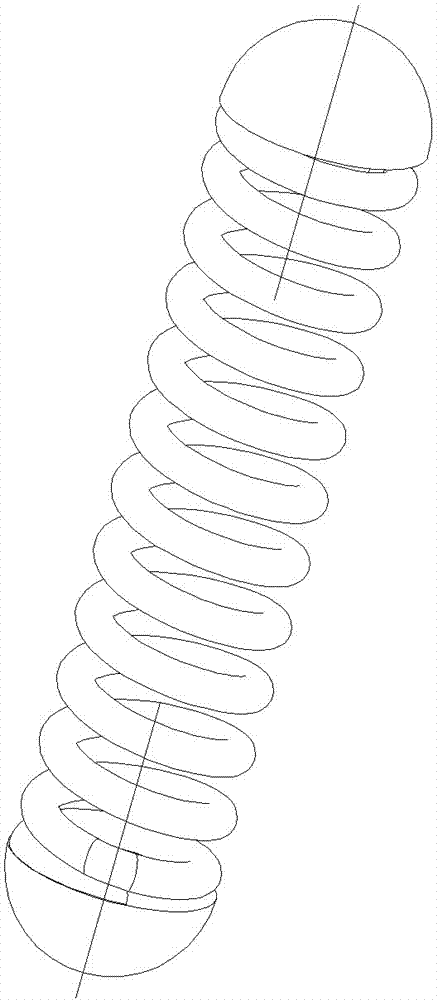

[0018] Examples of bow-shaped elastic contact reeds, such as Figure 4-6 As shown, the bow-shaped elastic contact reed includes two contact portions 11 at both ends and a connecting portion 12 connected between the two contact portions 11 .

[0019] The contact portion 11 is arc-shaped. In this embodiment, the contact portion 11 is arc-shaped. In use, the outer surface of the arc top of the contact portion 11 can be used as a contact surface with the mating connector.

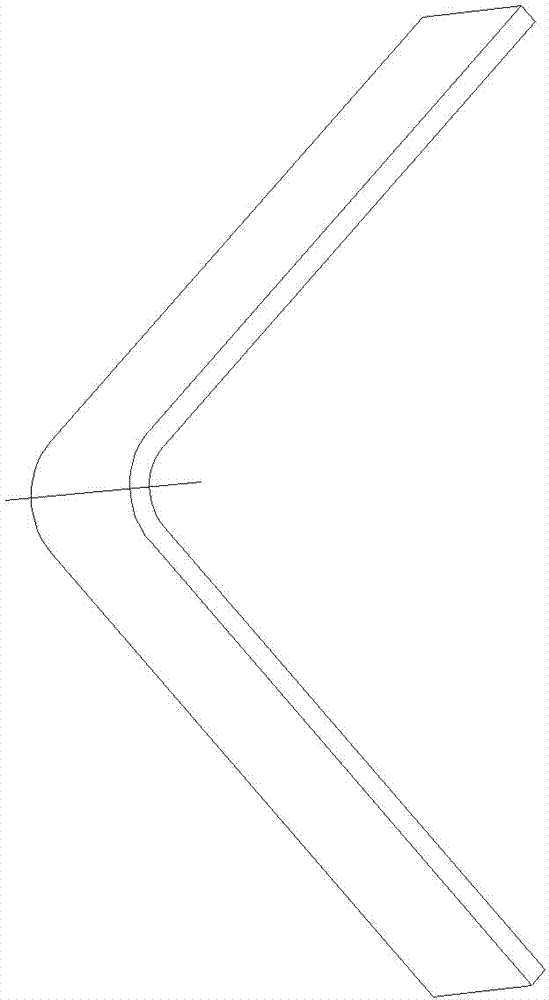

[0020] The connecting portion 12 is U-shaped. In this embodiment, the U-shape formed by the connecting portion 12 is not a standard U-shape. Specifically, it is because the two ends of the connecting portion 12 gradually approach each other, thus making it actually A U-shape with a tendency to close is formed on the upper part. On the one hand, this design is to guide the bending position of the connecting part 12 when both ends are pressed, and on the other hand, it is to increase its bending range, because be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com