Rail construction engineering van capable of changing rails

A technology of variable track and engineering vehicle, which is used in different widths of tracks, passenger cars, railway car body parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

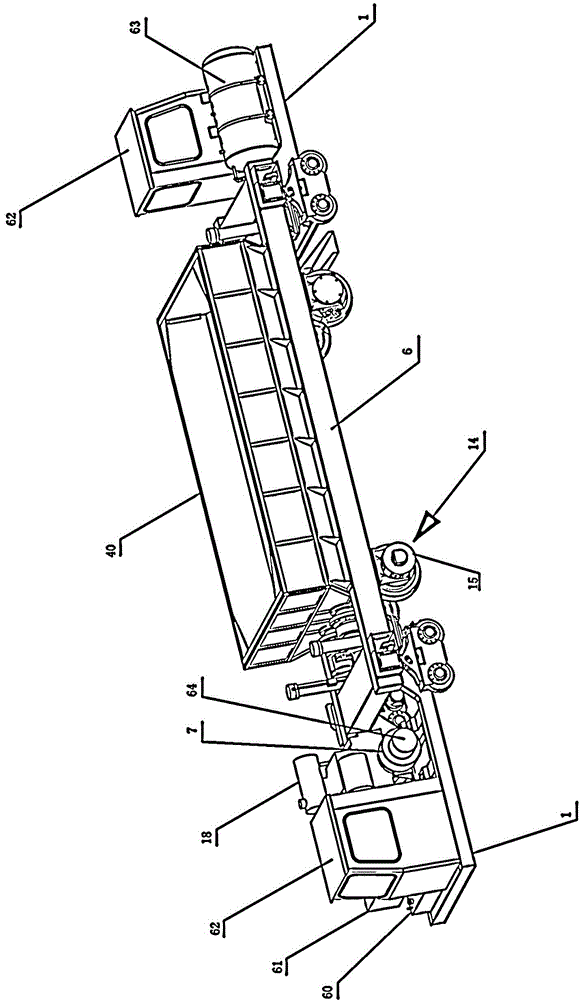

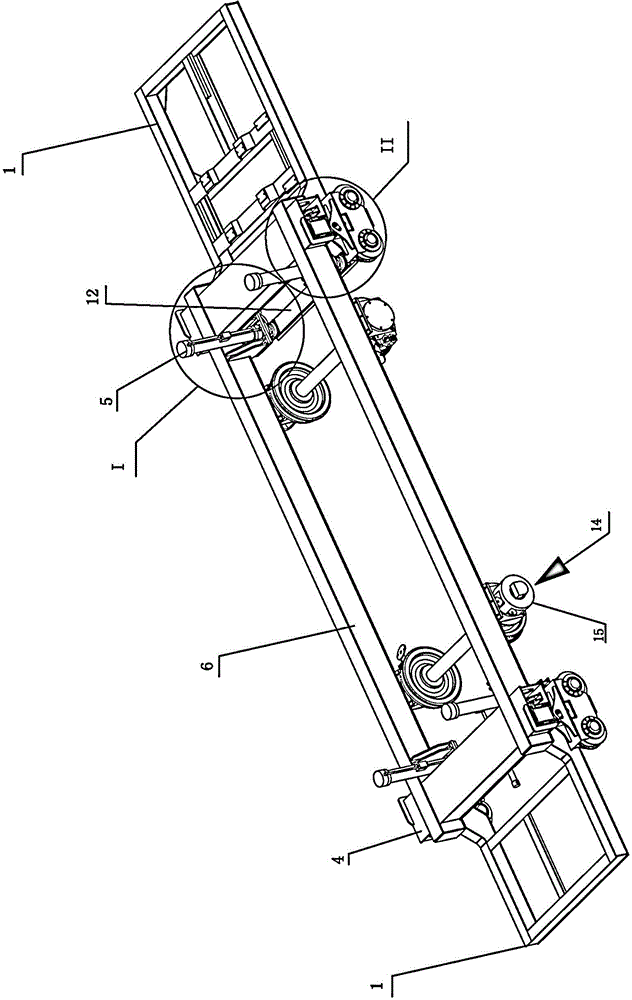

[0028] A variable rail track construction engineering vehicle, such as figure 1 and figure 2 As shown, it includes a main chassis 6, two pairs of inner rail wheels 14 connected with the main chassis 6, at least one pair of inner rail wheels 14 connected to a hydraulic motor 15, at least one pair of inner rail wheels 14 connected to a brake 22, and the main chassis 6 The upper part is connected with the hopper 40, and the two ends of the main chassis 6 are respectively connected with the auxiliary frame 1, and each auxiliary frame 1 is provided with a cab 62, and one end of the auxiliary frame 1 is connected with the engine 18, the fuel tank 61, the hydraulic oil tank 60, the hydraulic oil pump 7, The water pump 64 communicated with the hopper 40 is connected with the flushing water tank 63 communicated with the water pump 64 on the auxiliary frame 1 at the other end, and the following components.

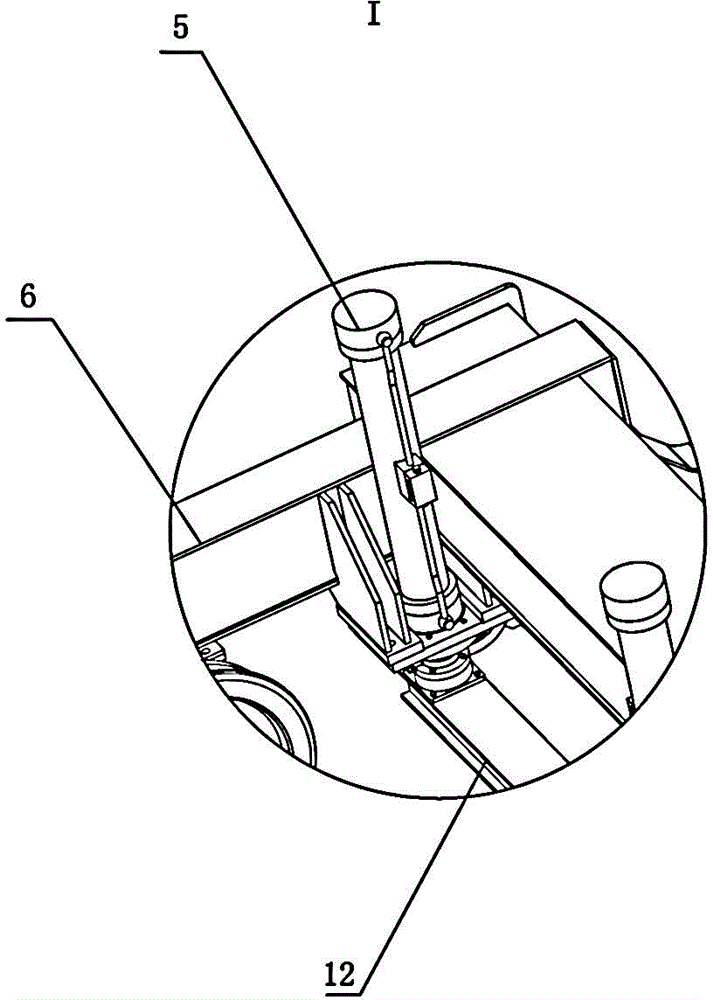

[0029] a. Lifting components:

[0030] Such as figure 2 and image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com