Titanium dioxide-based composite ceramic dielectric material, and preparation method and application thereof

A technology of titanium dioxide and composite ceramics, which is applied in the field of composite ceramic materials, can solve the problems of unfavorable practical application of comprehensive dielectric performance indicators of titanium dioxide ceramics and strontium titanate ceramics, and achieve enhanced electric field strength Eb, enhanced electric field strength, and accelerated crystallization. The effect of particle homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

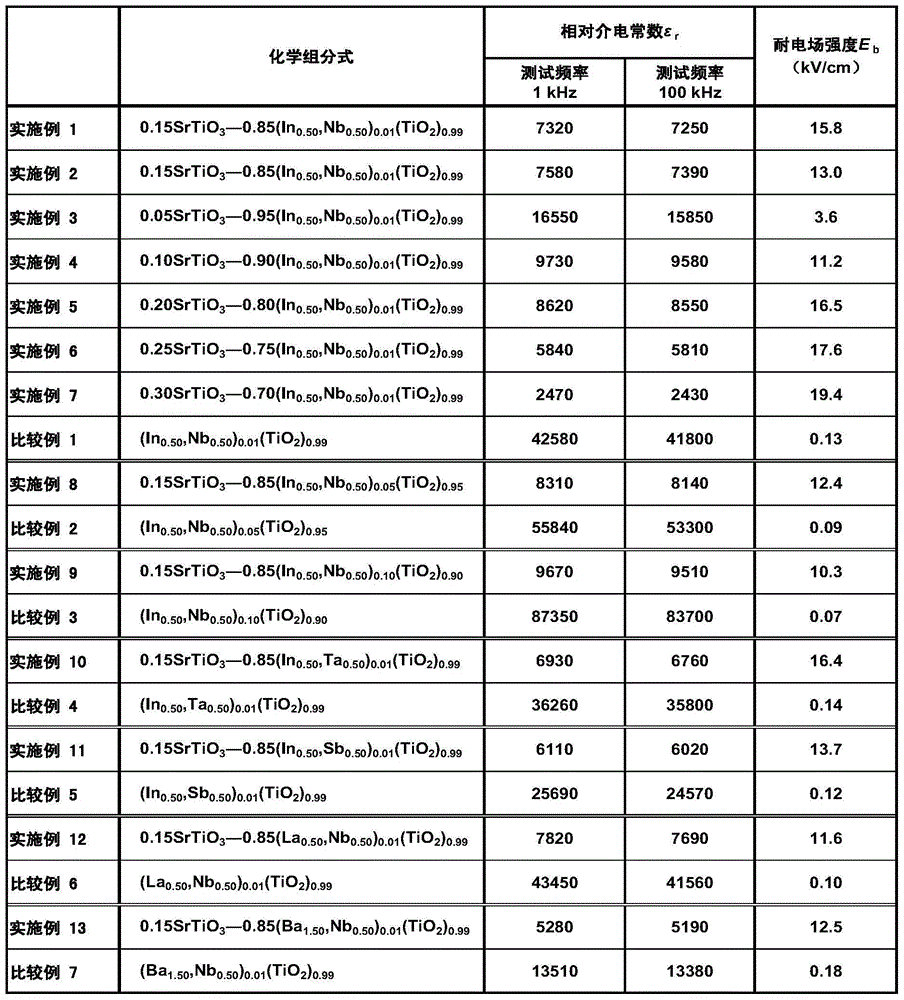

Examples

Embodiment 1

[0034] A titanium dioxide-based composite ceramic dielectric material, the chemical formula is as follows:

[0035] 0.15SrTiO 3 ―0.85 (In 0.50 ,Nb 0.50 ) 0.01 (TiO 2 ) 0.99 .

[0036] The preparation method of the above-mentioned titanium dioxide-based composite ceramic dielectric material adopts carbonate SrCO of analytical purity respectively. 3 (99.0%), oxide TiO 2 (99.8%), In 2 o 3 (99.0%) and Nb 2 o 5 (99.8%) as a raw material, a titanium dioxide-based composite ceramic sample was prepared using a traditional solid-state reaction process, the steps are as follows:

[0037] (1) Chemical expression of SrTiO by composition 3 The stoichiometric ratio of SrCO 3 and TiO 2 , after mixing, it is ball milled and dried, and then pre-fired at 1250°C for 3 hours to make the raw materials fully react; then ball milled and dried to obtain SrTiO 3 ceramic powder;

[0038] (2) Chemical expression by composition (In 0.50 ,Nb 0.50 ) 0.01 (TiO 2 ) 0.99 The stoichiometri...

Embodiment 2

[0042] A titanium dioxide-based composite ceramic dielectric material, the chemical formula is as follows:

[0043] 0.15SrTiO 3 ―0.85 (In 0.50 ,Nb 0.50 ) 0.01 (TiO 2 ) 0.99 .

[0044] The preparation method is as described in Example 1, except that the sintering time in step (4) is 10 h.

Embodiment 3

[0046] A titanium dioxide-based composite ceramic dielectric material, the chemical formula is as follows:

[0047] 0.05SrTiO 3 ―0.95 (In 0.50 ,Nb 0.50 ) 0.01 (TiO 2 ) 0.99 .

[0048] The preparation method is as described in Example 1, except that the ratio of raw materials is different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap