A Coarse and Thin Connection System Layout

An interconnected system and layout technology, applied in the direction of textiles and papermaking, can solve the problems of lack of consistency and versatility, troublesome management of roving varieties, unfavorable labor costs, etc., and achieve the effects of simple structure, improved production efficiency, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

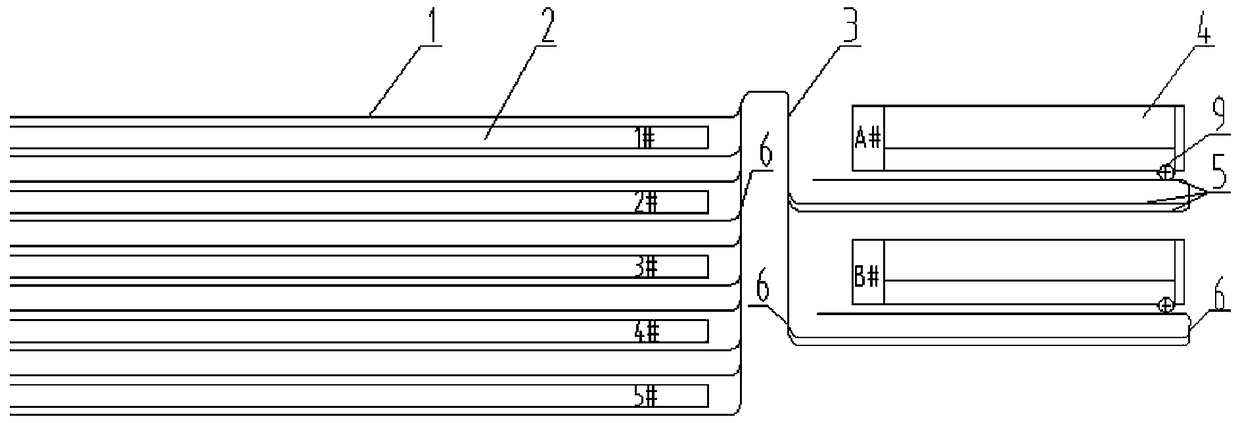

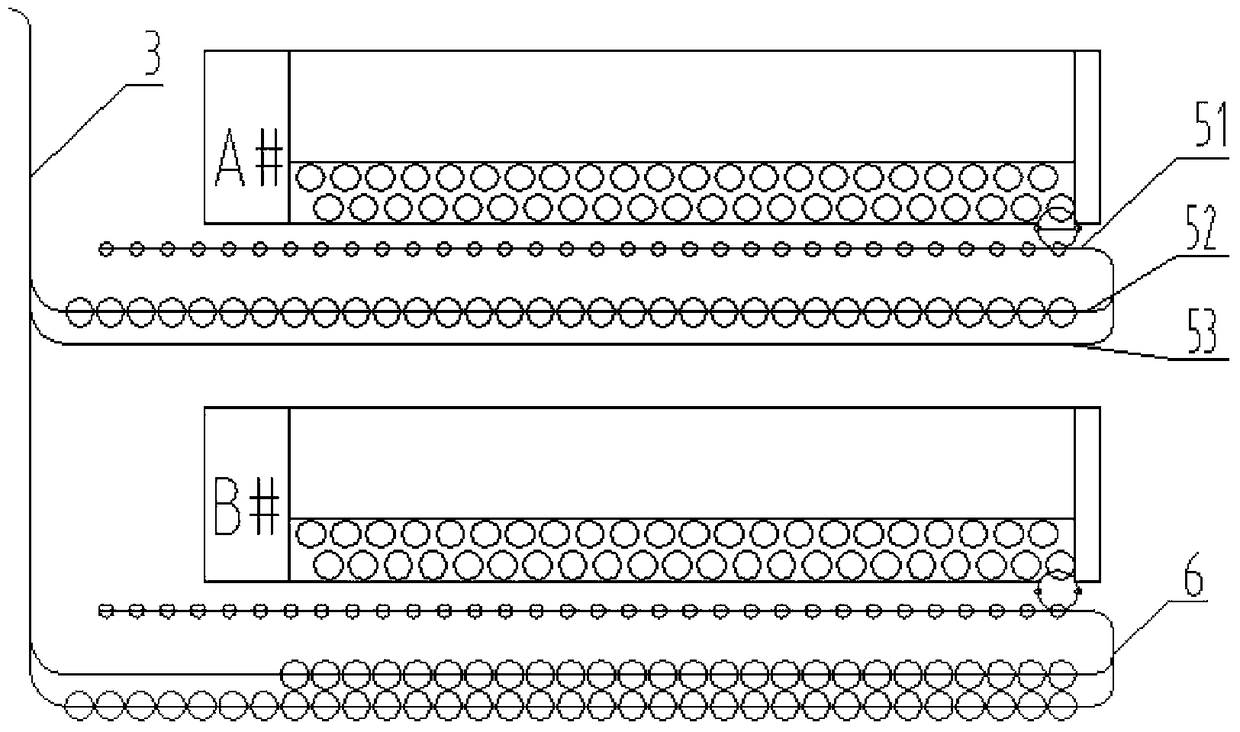

[0015] Embodiment 1: as figure 1 As shown in the figure, a layout of thick and thin interlinked system, including five spinning frames 2 (1#, 2#, 3#, 4#, 5#), each spinning frame corresponds to two rails for a total of ten spinning frames 1, respectively spinning A Two roving frames 4 of the B variety roving and the empty and full tube warehouses 5 corresponding to each roving frame one by one, each empty and full tube warehouse 5 includes an empty tube track 51 and two full tube tracks 52,53, two One end of the full tube track 52, 53 is connected to the empty tube track 51 through the track splitting device 6, and the other end is connected to the main track 3 through the track splitting device 6, and the main track 3 is connected to the spinning frame track 1 through the track splitting device 6. Connected, the empty tube track 51 is connected with the roving frame 4 through the empty and full tube switch 9.

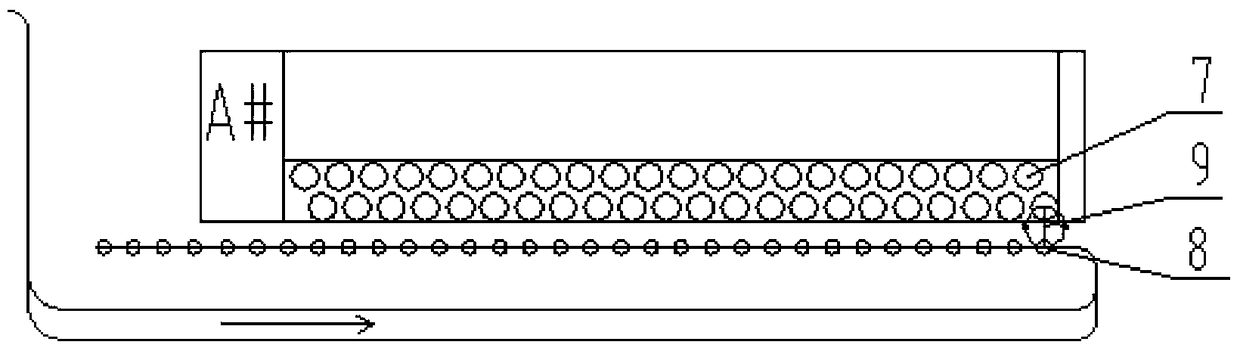

[0016] Such as image 3 As shown, the system transfers the empt...

Embodiment 2

[0021] Embodiment 2: as figure 2 As shown, the working principle is roughly the same as that of Embodiment 1, except that one end of the empty pipe track 51 is connected to two full pipe tracks 52 through the track separation and closing device 6, and the other end is directly connected to the main track 3 through the track separation and closing device 6. connected. Therefore, the empty tubes used up on the spinning frame 2 can directly enter the empty tube track of the roving frame 4 through the main track 3 and wait to be exchanged with the full yarn on the roving frame 4 without passing through two full yarn tracks 52 or 53. This method is sufficient With the effective connection between the tracks, the spinning efficiency can be further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com