Railway ballast sand removal vehicle

A technology for sand removal vehicles and ballast beds, which is applied in track cleaning, construction, cleaning methods, etc. It can solve the problems of high labor intensity, inconvenient handling of equipment, and long time consumption, and achieve good sand absorption effect and high sand absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

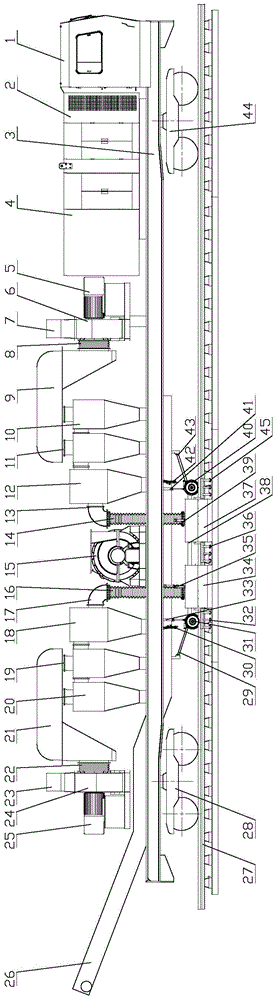

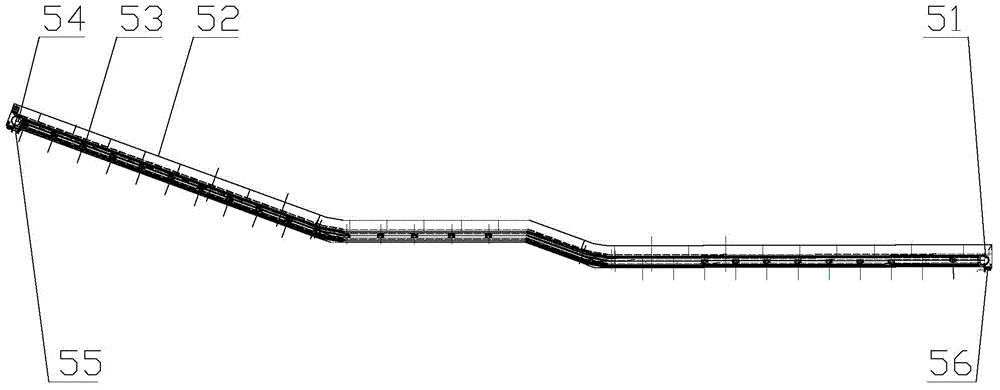

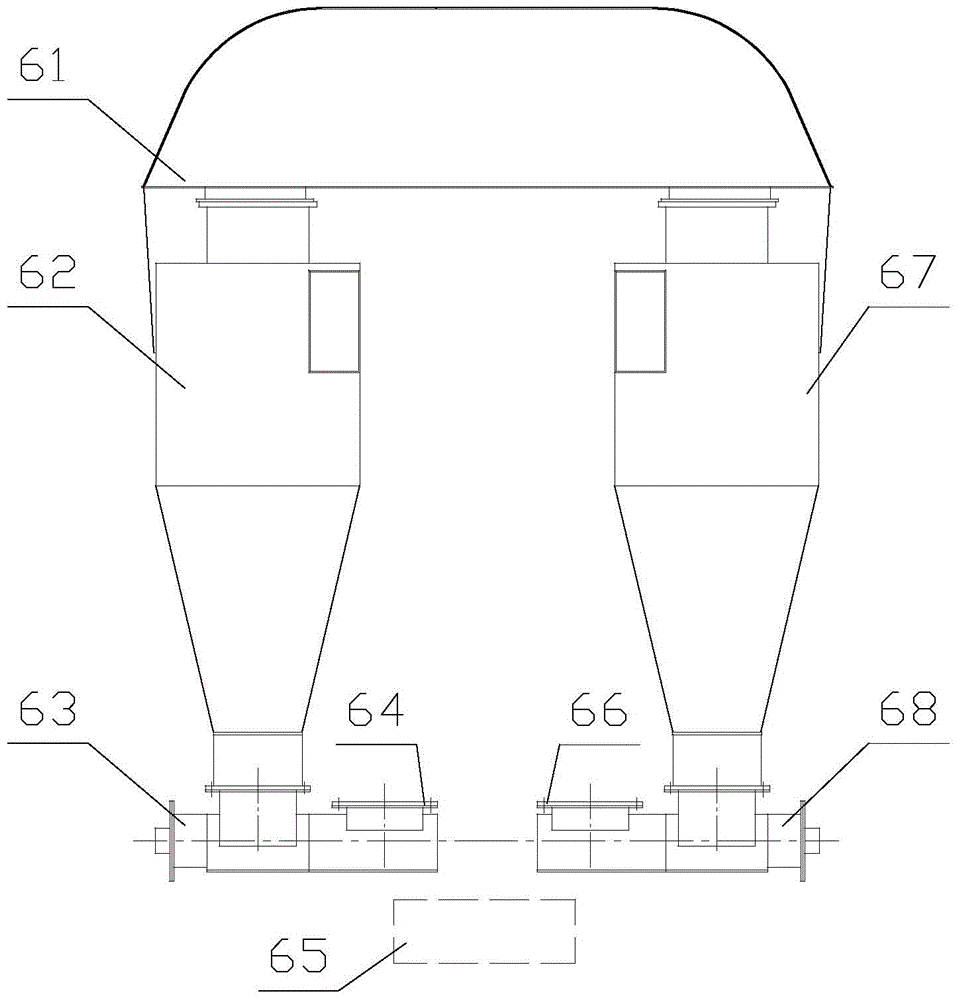

[0051] Embodiment 1.1, a kind of railway track bed desanding car, it comprises vehicle frame 3, and the driver's cab 1 is equipped with in the front of vehicle frame 3 tops, and the rear portion of driver's cab 1 is equipped with power room 2 and generator 4; The sand blowing blower 15 is fixed in the middle part above, and the front sand suction bellows 14 and the front sand suction air duct 13 are installed in front of the sand blower 15. The front end of the front sand suction air duct 13 is connected with a front gravity separator 12, and the front gravity separation The front cyclone separator 10 is connected to the device 12, and the front cyclone separator 10 is connected to the front air channel 9 through the front cyclone air duct 11, and the front air channel 9 is connected to the front sand suction fan 6 by the front suction bellows 8, and the front sand suction The top of the blower fan 6 is connected to the air outlet 7 of the front sand suction fan, and the front ...

Embodiment 12

[0070] Embodiment 1.2, the railway track bed desanding vehicle, is the same as Embodiment 1.1, except that the rear sand blowing pipe 32 is installed in the rear sand suction wind cover 34, and the front sand blowing pipe 45 is installed in the front sand suction wind cover 37.

Embodiment 13

[0071] Embodiment 1.3, railway track bed desanding vehicle, is the same as embodiment 1.1, the difference is that there is only one set of desanding device composed of sand suction bellows, sand suction air pipe, gravity separator and cyclone separator, etc. Be installed in the front or the rear of the sand fan 15 on the top of the vehicle frame 3; Correspondingly, a set of sand suction wind cover, sand blowing pipe, sand suction bellows and wind cover lifting cylinder etc. are only installed at the corresponding positions on the sand suction trolley frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com