Manual permanent magnet sand sucker and application method thereof

A sand suction and permanent magnet technology, applied in the field of manual permanent magnetic sand suction, can solve the problems of abnormal system operation, increase production cost, disadvantageous mass production, etc., and achieve the best sand suction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

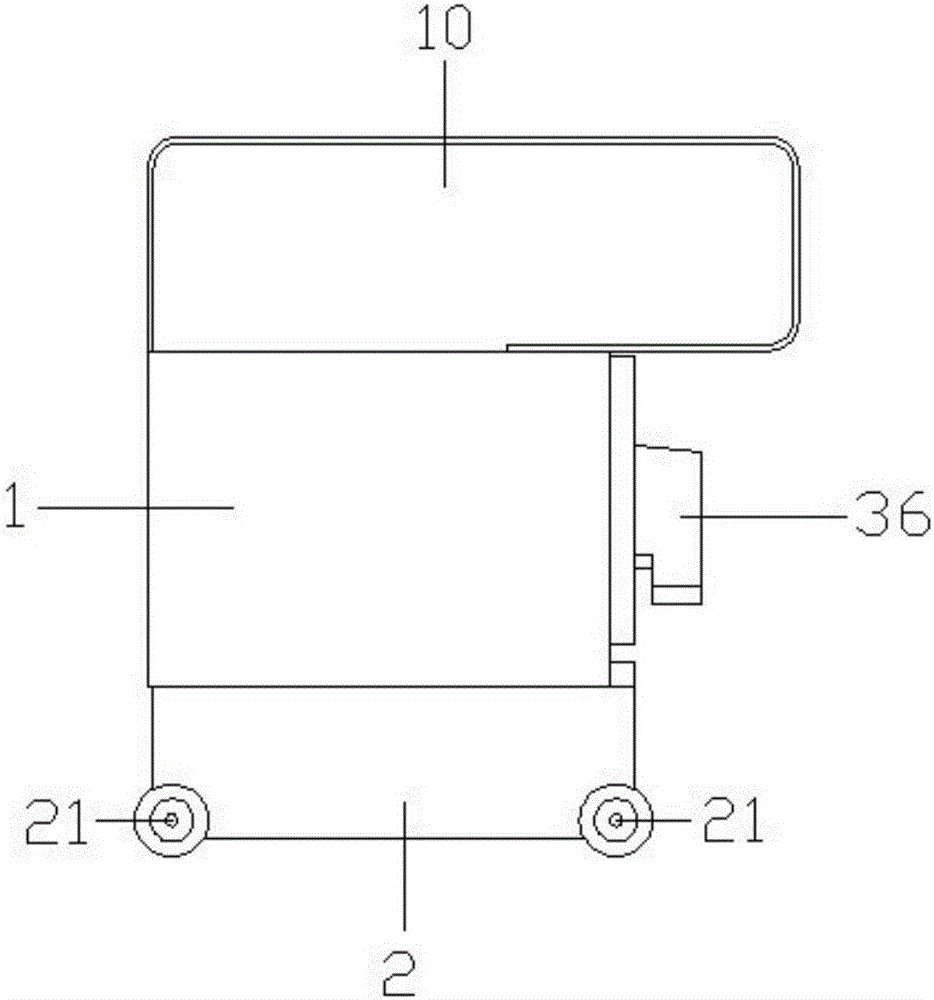

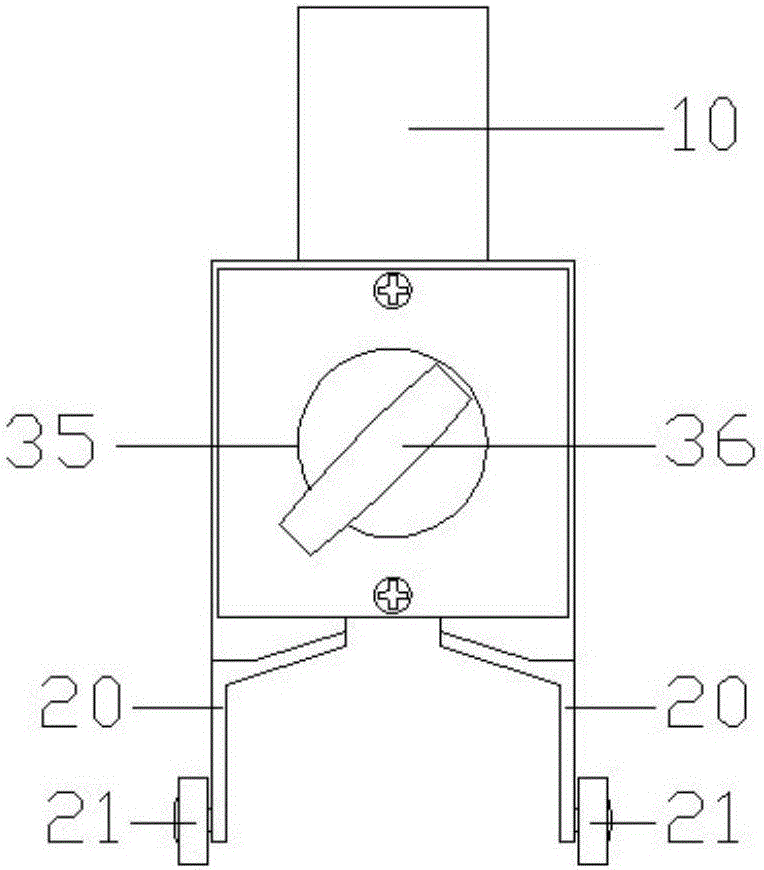

[0037] see figure 1 with figure 2 As shown, a manual permanent magnetic sand sucker of the present invention includes a main body 1, the main body 1 is a hollow shell, and the hollow part of the shell forms a storage space; the upper end of the main body 1 is provided with a hand-held part 10, A support 2 is fixed on the lower surface. The bracket 2 is composed of two parallel support frames 20 , and the two support frames 20 are respectively fixed on both sides of the lower surface of the main body part 1 . Wherein, the materials of the two supporting frames 20 are both A3 steel. The supporting frame 20 is provided with rollers 21, which is convenient for users to operate.

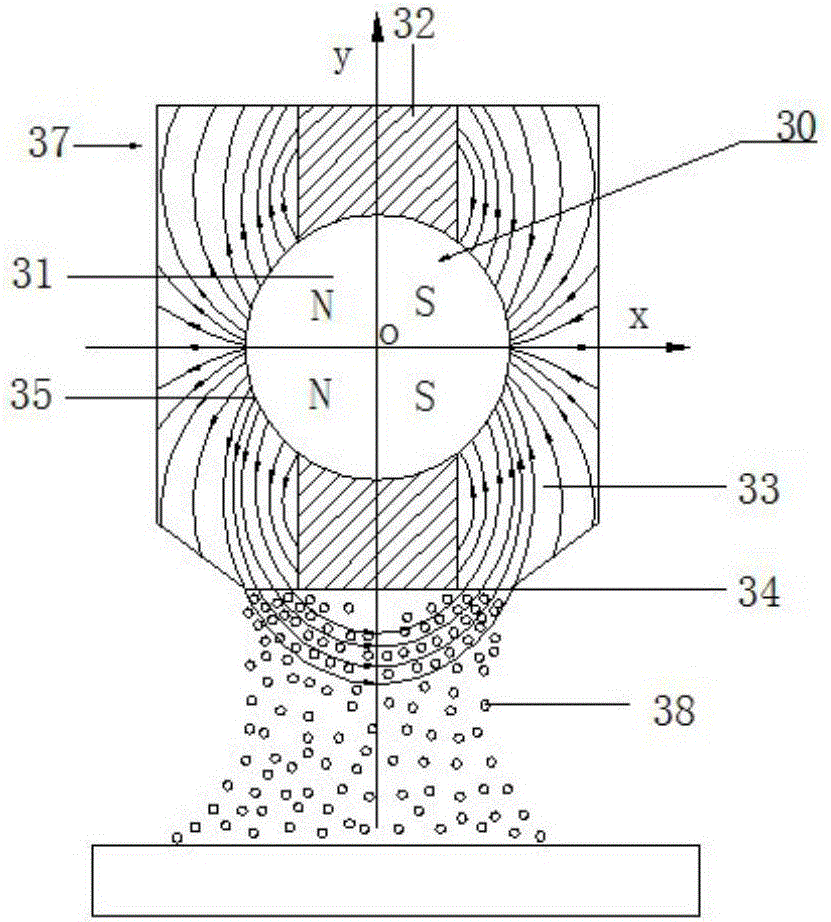

[0038] Please also refer to Figure 1 to Figure 4 A magnetic sand-absorbing device 3 is housed in the housing space of the main body 1 , and the magnetic sand-absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com