An auxiliary coal and sand suction device on the side of the track and its corresponding track sand removal vehicle

A technology for sand removal vehicles and tracks, which is applied in track cleaning, construction, cleaning methods, etc., and can solve problems such as secondary pollution of sand and unsatisfactory sand removal operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

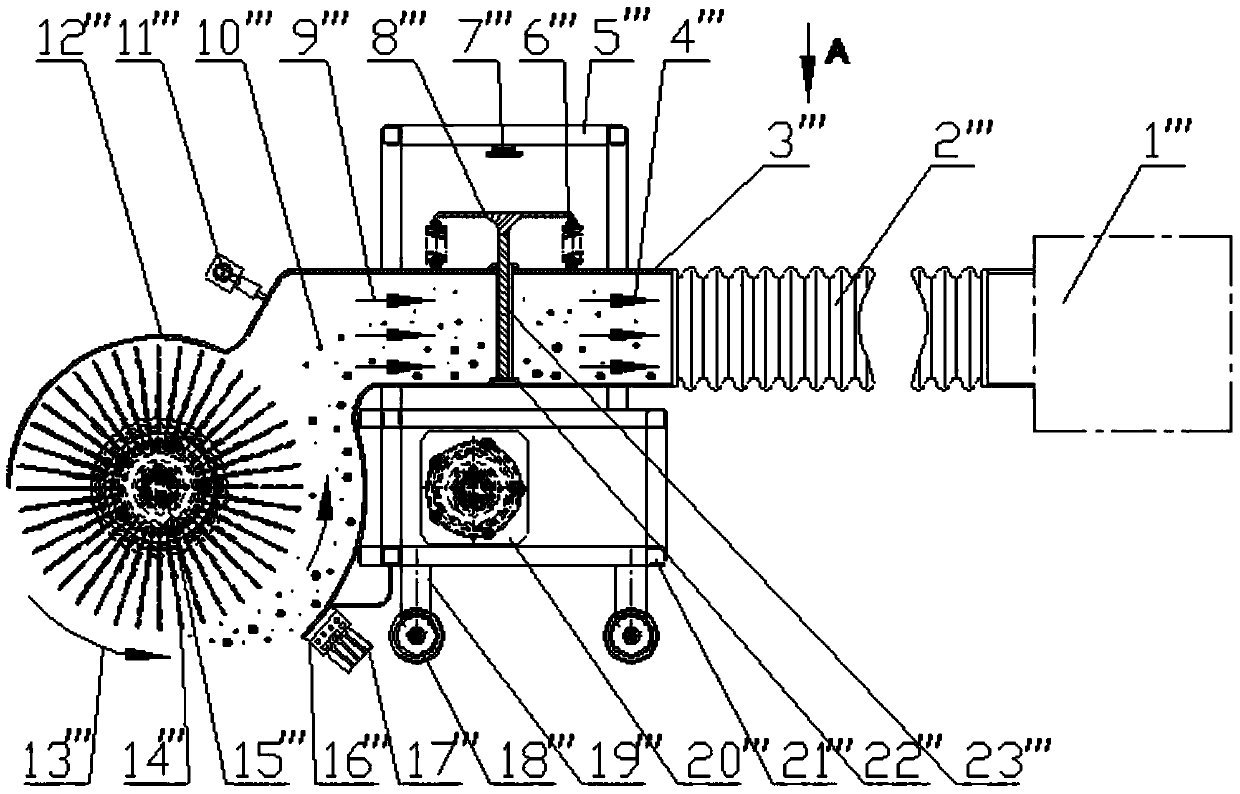

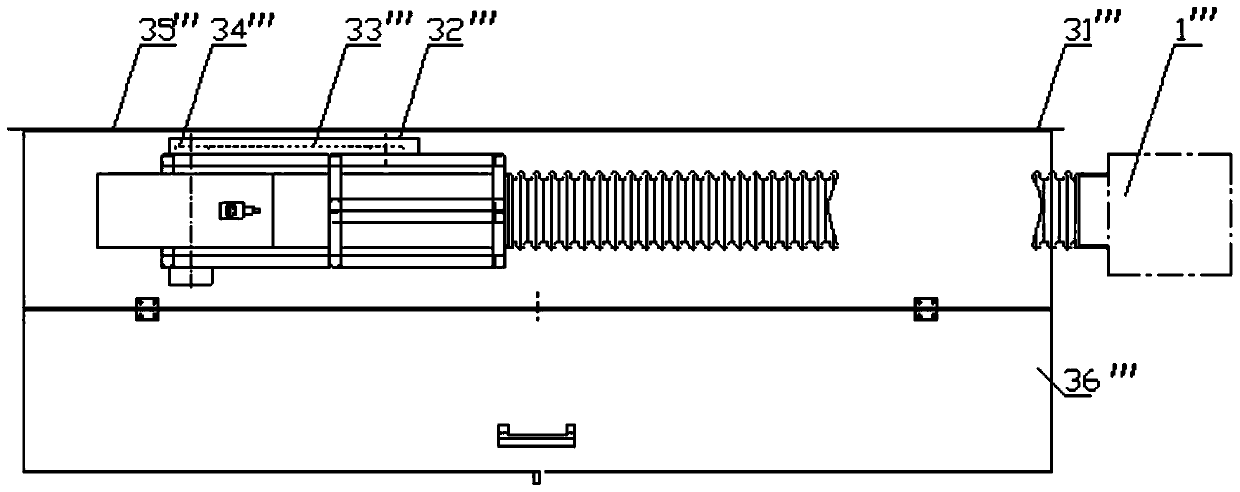

[0070] Embodiment 1.1, an auxiliary coal and sand suction device on the side of the track, which includes a coal suction pipe body 3"', the front end of the coal suction pipe body 3"' is connected to the separation part 1"' through a coal suction hose 2"', The middle of the coal suction pipe body 3"' is fixed with a protrusion 22"', and the coal suction pipe body 3"' above the protrusion 22"' is equipped with a damper 23"', and the upper part of the damper 23"' is connected to the coal suction pipe body 3"' external damper handle 8"', the two sides of the damper handle 8"' hang springs, and the lower part of the spring is connected to the outer side of the coal suction pipe body 3"'; the upper part of the coal suction pipe body 3"' is equipped with an auxiliary Handle 5"', the auxiliary handle 5"' is installed directly above the damper handle 8"', the motor switch 7"' is fixed under the auxiliary handle, and the rear of the coal suction pipe body 3"' is connected to the roller ...

Embodiment 21

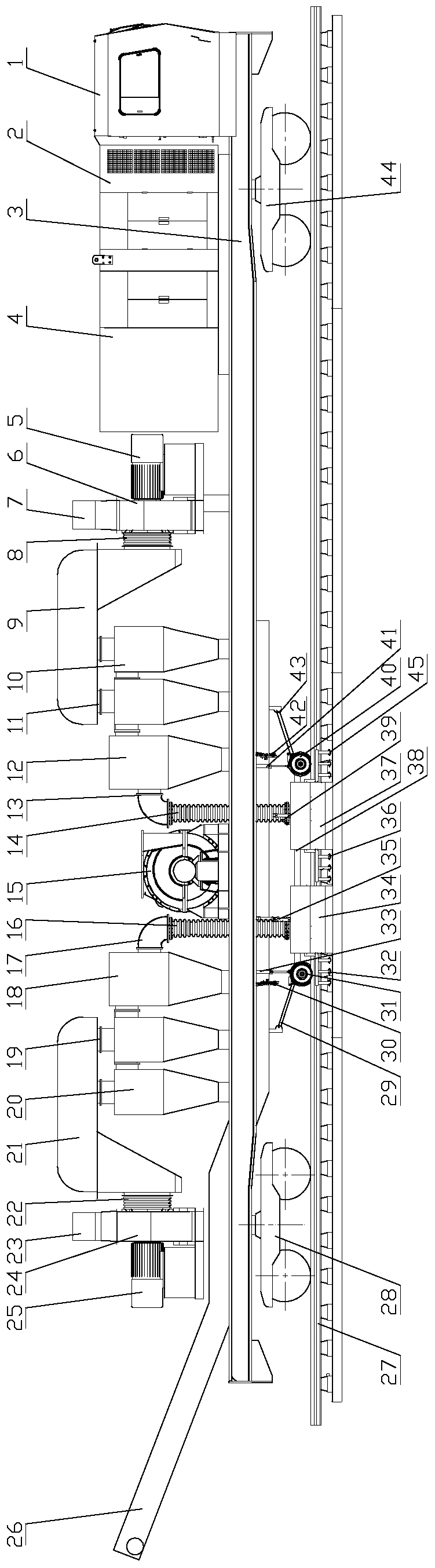

[0080] Embodiment 2.1, a track desanding vehicle with side auxiliary coal suction and sand suction devices, which includes a vehicle frame 3, a driver's cab 1 is installed in front of the upper part of the vehicle frame 3, and a power room 2 is installed in the rear of the driver's cab 1 And generator 4; In the middle part above the vehicle frame 3, the sand-blowing fan 15 is fixed, and the sand-absorbing bellows 14 and the sand-absorbing air duct 13 before the sand-absorbing air duct 13 are installed in the place ahead of the sand-blowing fan 15, and the front end of the sand-absorbing air duct 13 is connected with The front gravity separator 12 is connected to the front cyclone separator 10, the front cyclone separator 10 is connected to the front air channel 9 through the front cyclone air duct 11, and the front air channel 9 is connected to the front air duct 8 by the front suction bellows 8. Sand-absorbing fan 6, the front sand-absorbing fan 6 is connected to the front san...

Embodiment 22

[0099] Embodiment 2.2, a track desanding vehicle with side auxiliary coal suction and sand suction devices, is the same as embodiment 2.1, the difference is that the rear sand blowing pipe 32 is installed in the rear sand suction wind hood 34, and the front sand blowing pipe 45 are installed in front suction sand wind cover 37.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com