Casting sand cleaning equipment

A technology for cleaning sand and equipment, which is applied in the direction of casting molding equipment, cleaning/processing machinery for casting mold materials, metal processing equipment, etc. It can solve the problem of granular debris splashing into adjacent pits, which is difficult to clean It is difficult to control the angle to achieve the effect of wide sand suction range, high sand suction efficiency and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in combination with specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

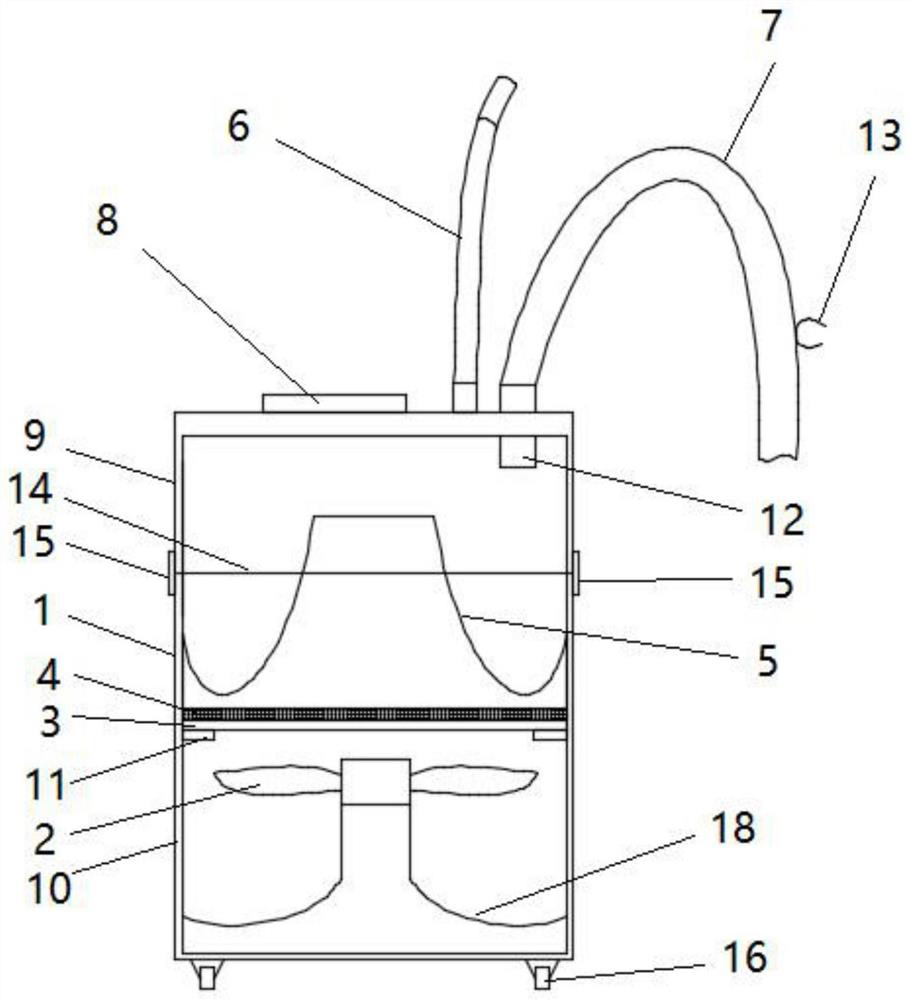

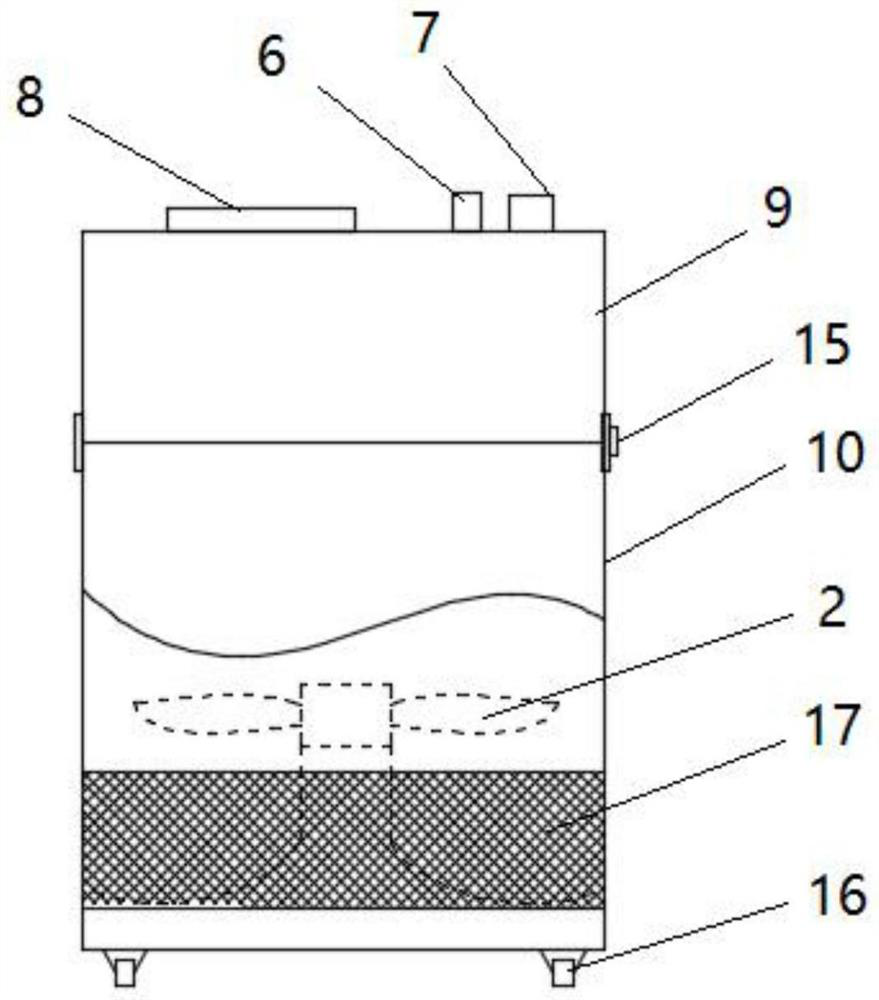

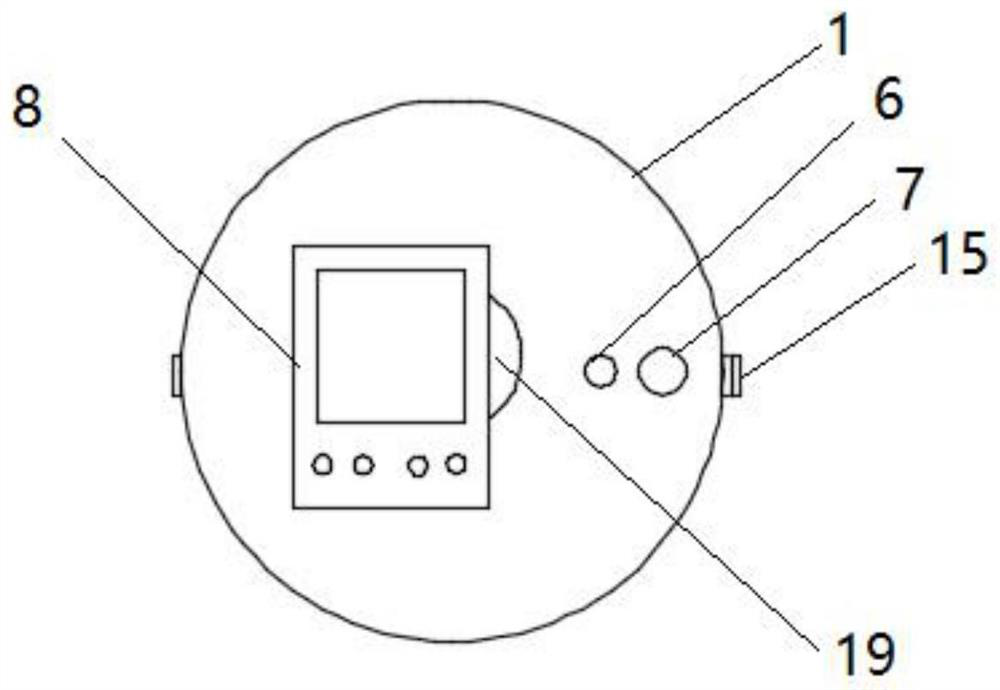

[0024] Such as Figure 1-7 As shown, the mold sand cleaning equipment is characterized in that it includes a sand suction box 1, a suction fan 2, a filter screen 3, a filter element 4, a sand collecting device 5, an endoscope 6, a sand suction pipe 7, a control device 8; the sand suction box 1 is divided into an upper box body 9 and a lower box body 10, the sand suction box 1 is cylindrical, and a limit end 11 is provided on the inner side of the middle part of the lower box body 10 for installation Filter screen 3, filter core 4 and sand collection device 5, the top of the right end of the upper box 9 is provided with a sand suction hole 12 for installing the sand suction pipe 7; the suction fan 2 is installed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com