Suction shield head for seabed sand suction operation

A shield head and water inlet technology, applied in mechanically driven excavators/dredgers, etc., can solve the problems of material wear, large resistance, and high requirements for equipment materials, and achieve high efficiency, reasonable structure design, and high sand suction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

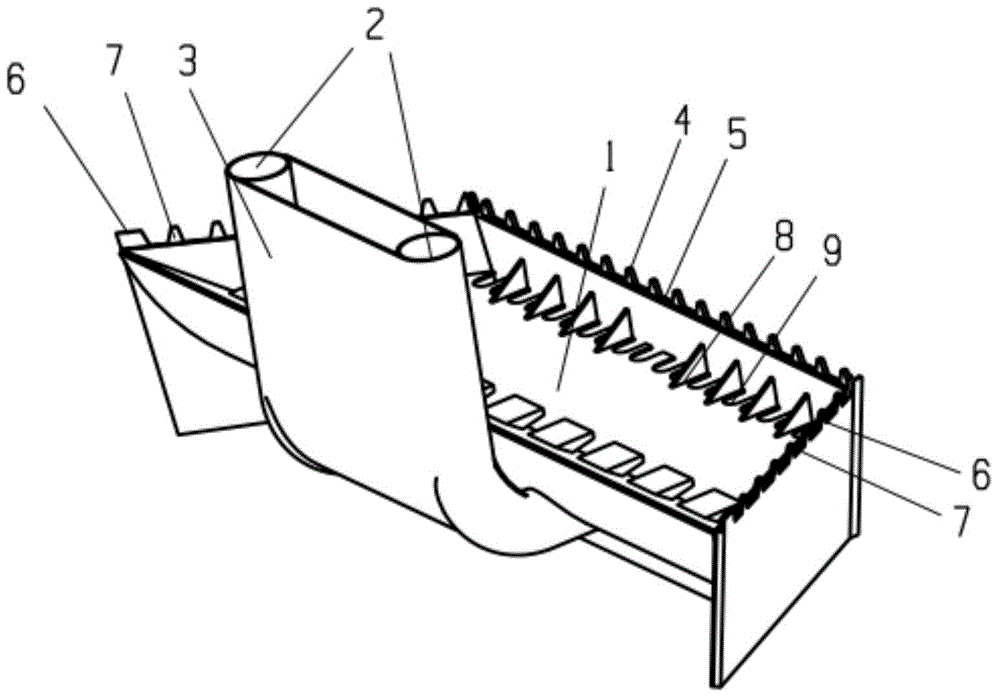

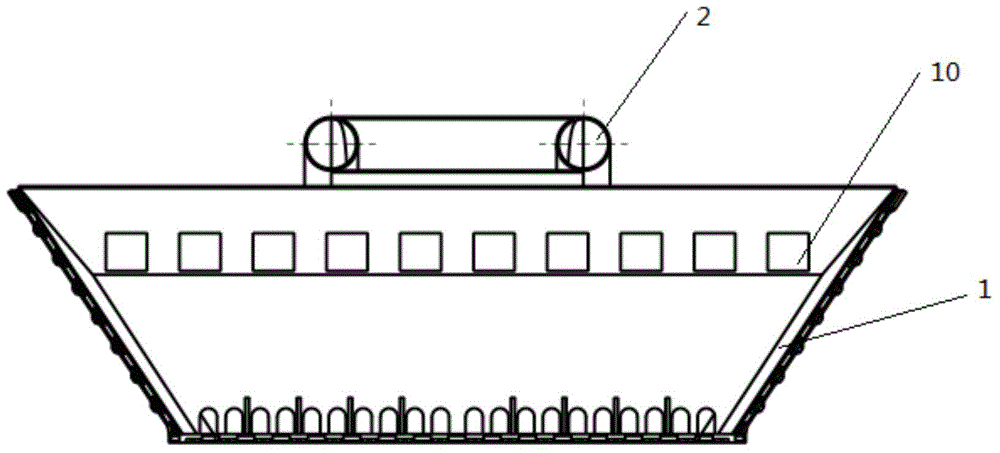

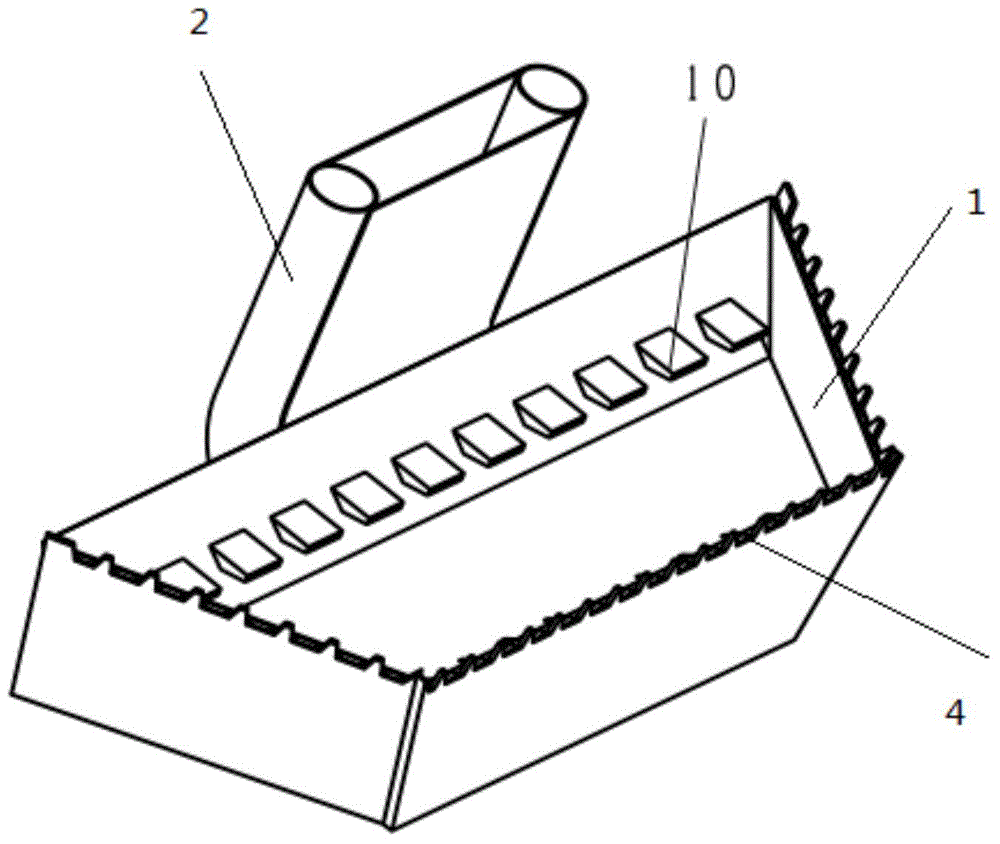

[0015] Referring to the accompanying drawings, the special suction shield for seabed sand suction operation includes a sand bin 1, the sand bin has a trapezoidal structure, and a water inlet 2 is welded on the front end of the sand bin, and the water inlet 2 is formed by two round pipes. Composition, the square structure in the middle of the water inlet 2 is the sand pumping port 3; there is a toothed structure 4 on the rear end surface of the sand bin 1, and the gap opened between the toothed structures 4 is the water outlet 5, and the sand bin 1 There are zigzag structures 6 respectively on the left and right end surfaces of the zigzag structures 6, and the gaps opened between the zigzag structures 6 are water outlets 7; the bottom surface of the sand bin 1 near the rear end surface is separated by a triangular plate 8 as a sand suction port. 9. A water outlet 10 is welded below the front end of the sand bin 1 .

[0016] When the special suction shield head for seabed sand s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com