Vibration rod guiding device

A technology of guiding device and vibrating rod, which is applied in the direction of construction, building structure, and building material processing, etc., and can solve the problems of formwork friction, difficult insertion of vibrating rods, and failure of vibrating rods to be correctly positioned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

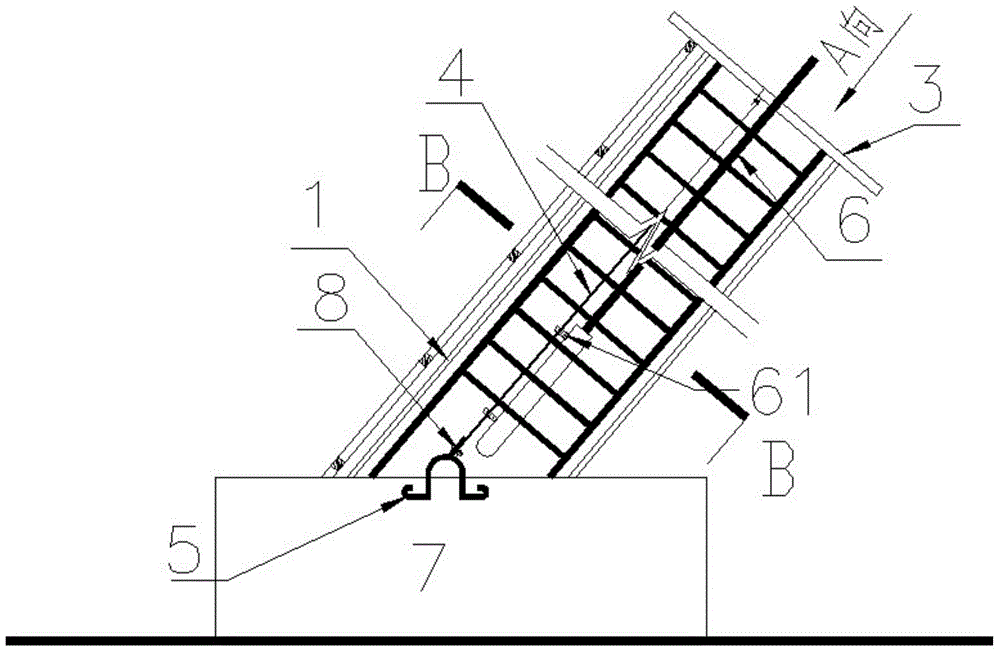

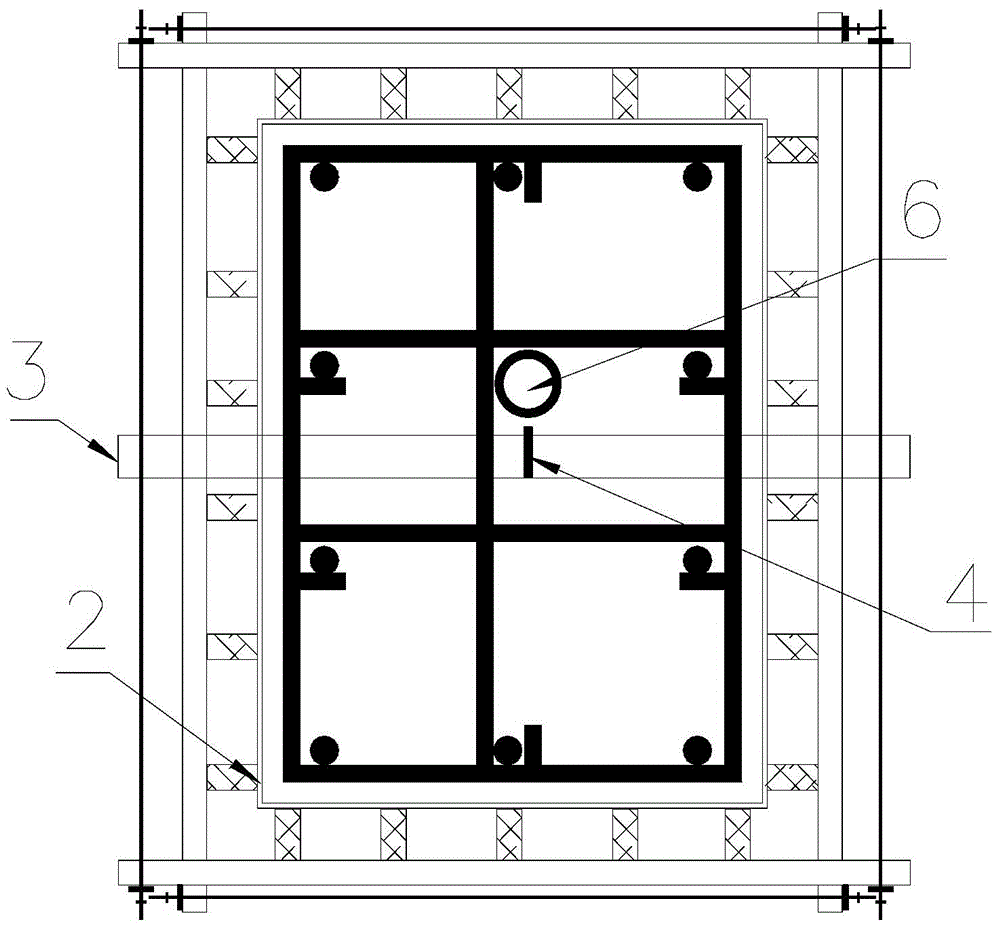

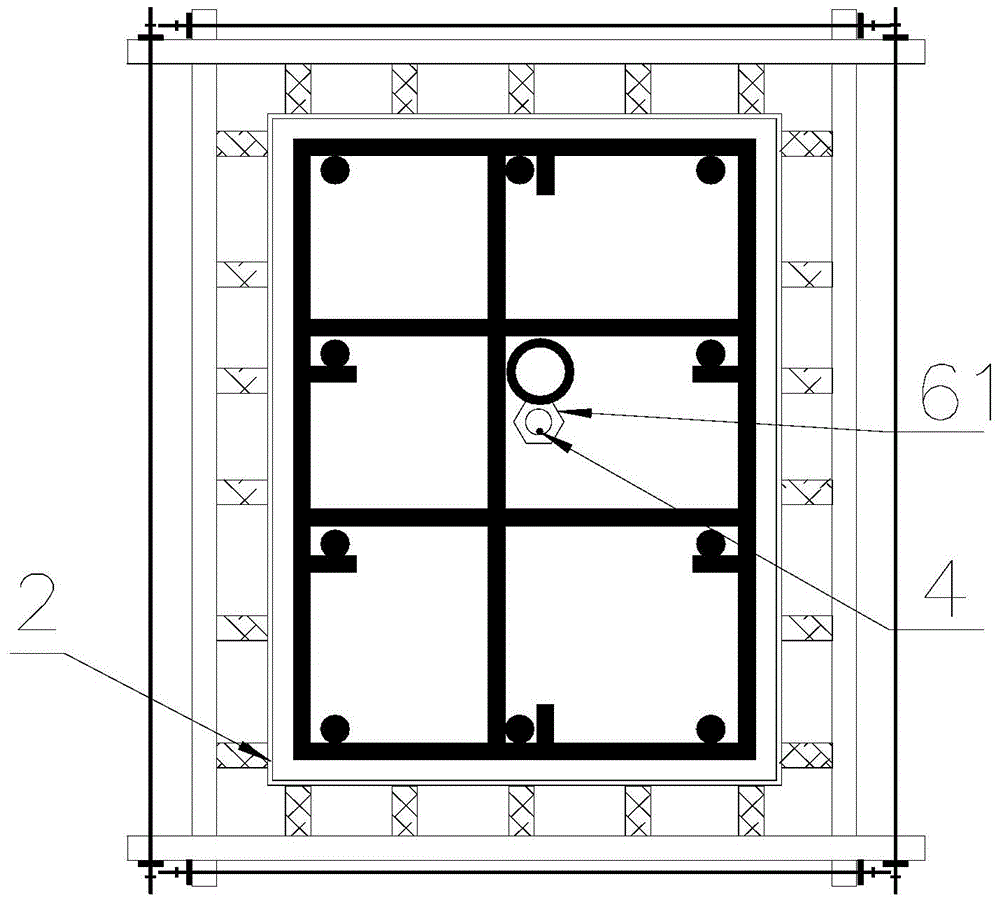

[0019] Embodiment 1 The vibrator guide device of the present invention includes an outer frame 1, a cross arm 3, a guide wire rope 4, and a pre-embedded collar 5 that are set outside the formwork frame 2. The bottom of the outer frame 1 is fixed on the On the corresponding foundation 7 at the bottom of the vibrating rod 6, and the embedded collar 5 is fixed on the foundation 7; the cross arm 3 is fixed on the top of the outer frame 1, and the side of the vibrating rod 6 A plurality of guide rings 61 for penetrating guide wire ropes are arranged in the axial direction of the wall; the bottom of the guide wire rope 4 is fixed on the embedded collar 5, and the upper end passes through the guide rings 61 and is fixed on the cross arm 3 to keep the whole The guide wire rope 4 is under tension.

[0020] The outer frame 1 is in the same shape as the formwork frame 2 surrounding the vibrating rod 6, and the cross section is square.

[0021] The central axis of the cross arm 3 is perp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com