Heat gun and heat gun system

A technology of hot air gun and hot air gun barrel, which is applied in the direction of air heater, fluid heater, lighting and heating equipment, etc., and can solve the problems of overheating and blowing of heating elements, damage of hot air gun fan, and air supply of fan blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

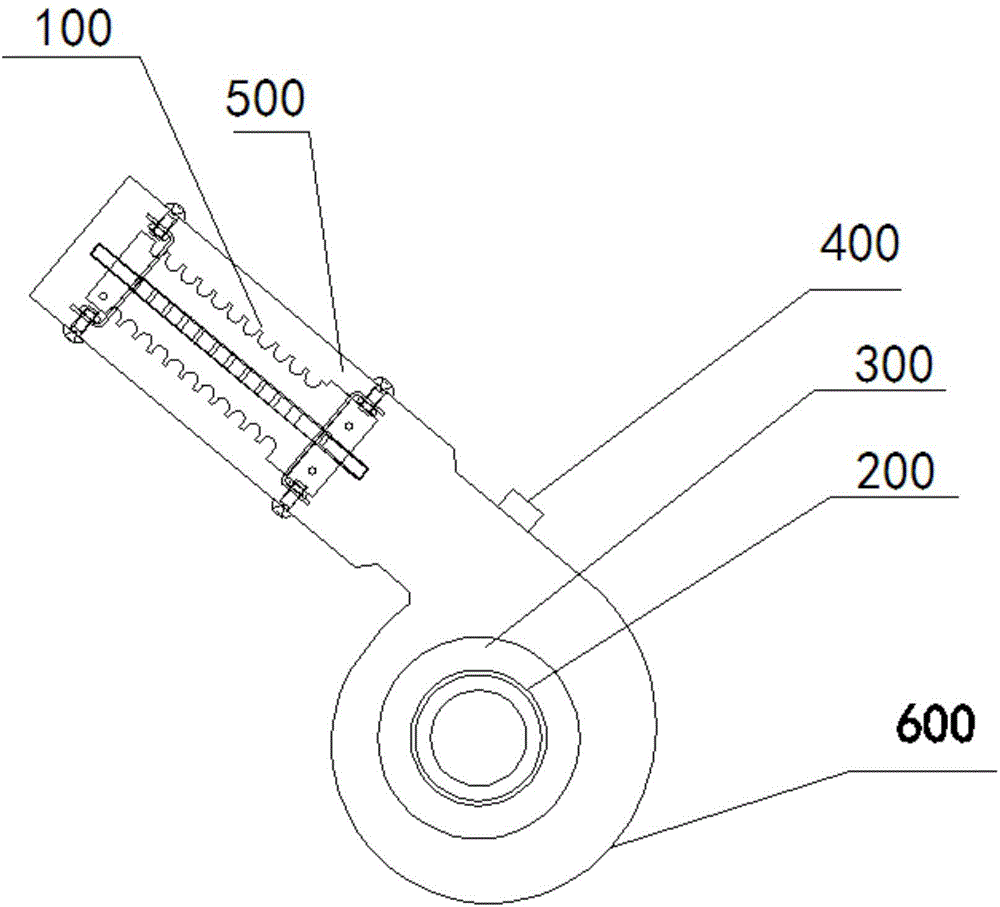

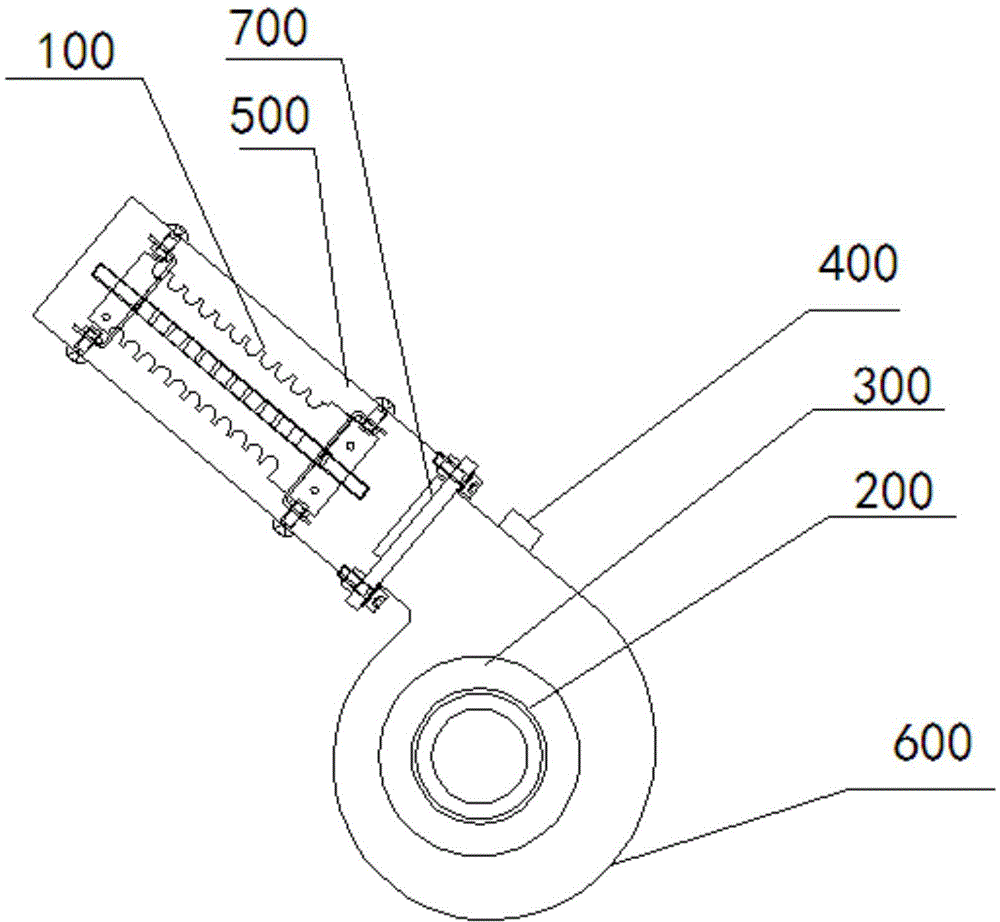

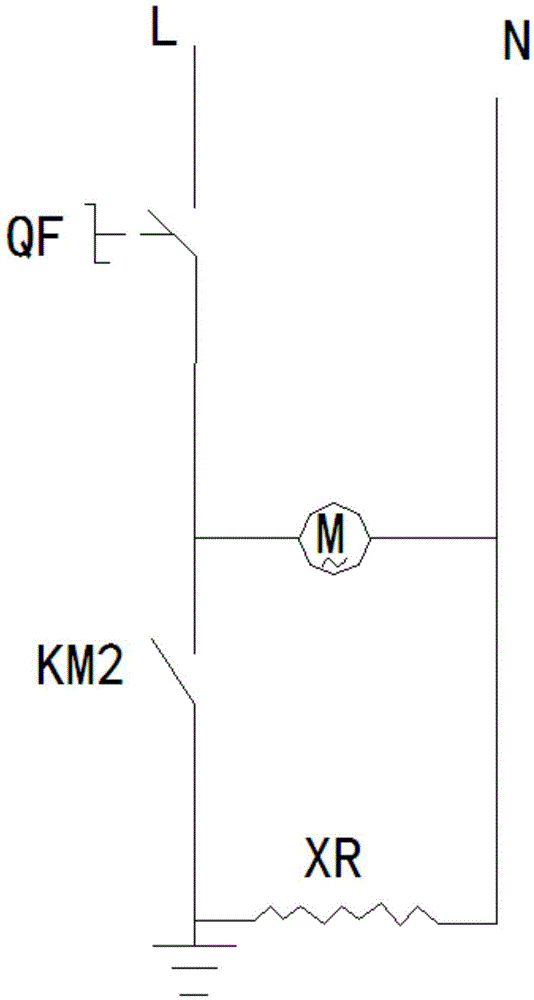

[0025] see figure 2 According to the advantages of the present invention, a heat gun is provided, including a heat gun body, a heating element 100, a fan 200, fan blades 300 and a control switch 400, where the heating element can be a heating wire; the heat gun body includes a hot air The gun barrel 500, the heat gun chamber 600, the heat gun barrel 500 is connected with the heat gun chamber 600; the heating element 100 is fixed in the heat gun barrel 500, the fan 200 is connected with the fan blade 300, and the fan and the fan blade are fixed in the heat gun chamber. The heat gun also includes a pressure sensor 700, which is fixed in the heat gun barrel. The pressure sensor is used to detect whether the fan is running. When the fan is not running, the pressure sensor can control the heating element to be powered off. The fixing of the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com