Single camera based power device shaft torque, rotation speed and power parameter measurement methods

A power device and single-camera technology, applied to devices using optical methods, power metering, measuring devices, etc., to achieve high precision, real-time power monitoring, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

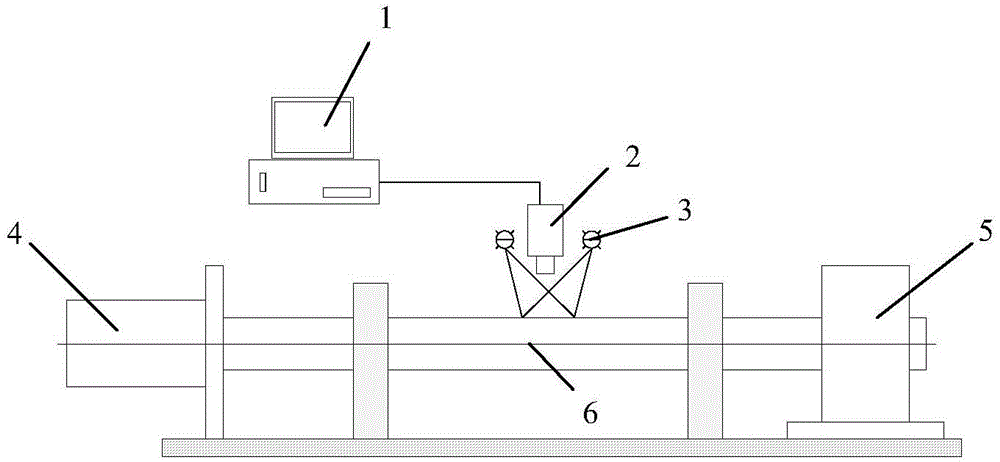

[0030] combine figure 1 , illustrate the implementation process of the present invention:

[0031] Based on the single camera shaft torque, speed, and power measurement method of the power unit, the power unit 4, the transmission shaft 6, and the load 5 are connected in sequence;

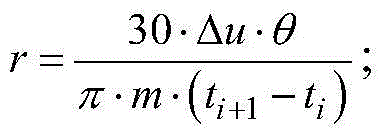

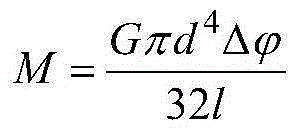

[0032] On the outer peripheral surface of the drive shaft, a circle of random marking patterns is arranged. The above random marking patterns are formed by grinding the shaft surface and repeatedly spraying black and white glass bead paint to form randomly distributed discrete spots, that is, artificial digital speckle fields; The corresponding camera 2 is arranged at the random logo pattern, and a pair of ring-shaped LED light sources 3 are placed near the camera to provide light for the camera; the camera is connected to the host computer 1, and an image storage unit is distributed in the host computer to store the camera image data, and includes shooting Time information; the upper computer uses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com