A sealing structure suitable for thin bipolar plate with position limiting function

A sealing structure and bipolar plate technology, which is applied in fuel cells, solid electrolyte fuel cells, sustainable manufacturing/processing, etc., can solve the problems of insufficient bonding force and friction between sealing sheets and polar plates, difficulty in ensuring sealing reliability, membrane Electrode physical structure failure and other problems, to achieve the effect of preventing short circuit between thin metal bipolar plates, stable and reliable sealing performance, and preventing single cell overpressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

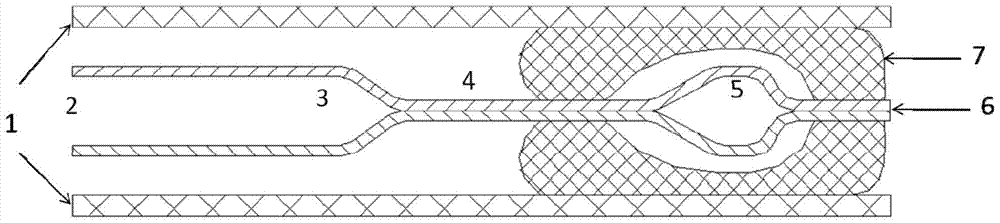

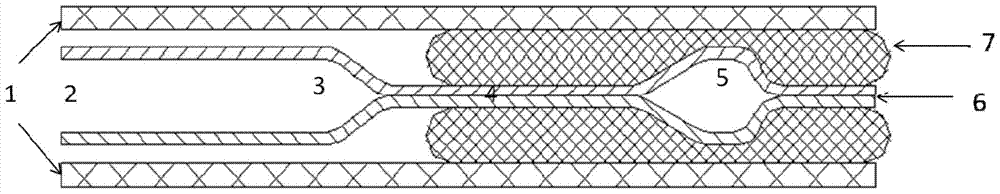

[0022] The proton exchange membrane fuel thin bipolar plate is a 0.2mm thick 304SS stainless steel thin bipolar plate. There is a sealing groove on the thin bipolar plate, and there are raised thin bipolar plate sealing groove inner edges 3 and thin double The outer edge 5 of the sealing groove of the electrode plate; there is a groove on the sealing glue line 7 corresponding to the protrusion on the outer edge 5 of the thin bipolar plate sealing groove; the thickness of the groove of the sealing glue line 7 is that the center of the membrane electrode is higher than the frame of the membrane electrode 1 times the height difference; the volume of the sealing glue line 7 in the sealing groove accounts for 60% of the total cross-sectional area of the sealing groove; the outer edge of the sealing glue line 7 is flush with the outer edge of the thin bipolar plate 2 and the membrane electrode frame 1 The surface of the glue line 7 in contact with the membrane electrode frame 1 is ...

Embodiment 2

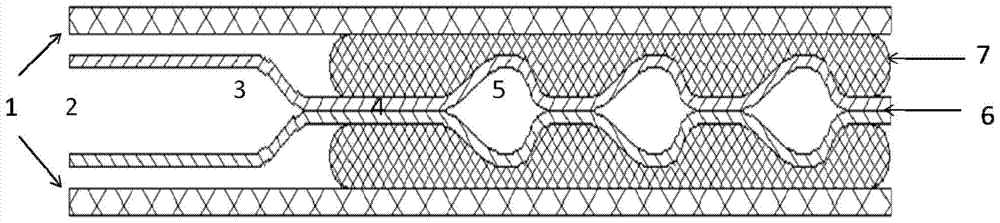

[0024] The proton exchange membrane fuel thin bipolar plate is a 0.08mm thick 316L stainless steel thin bipolar plate. There are 3 sealing grooves on the thin bipolar plate, and there are protruding thin bipolar plates on both sides of each sealing groove. The outer edge 5 of the sealing groove of the bipolar plate; there are three grooves on the sealing glue line 7 corresponding to the protrusions on the outer edge 5 of the thin bipolar plate sealing groove; the thickness of the groove of the sealing glue line 7 is the height of the membrane electrode center above the frame 3 times of the difference; the ratio of the volume of the sealing glue line 7 in the three sealing grooves 4 to the total cross-sectional area of the sealing groove here is 60%, 100% and 100% from the inside to the outside; the outer edge of the sealing glue line 7 and the The outer edges of the thin bipolar plate 2 and the membrane electrode frame 1 are flush, and the contact surface between the sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com