The electromagnetic valve

A solenoid valve and valve seat technology, applied in the field of solenoid valves, can solve the problem of inability to discharge air to the outside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

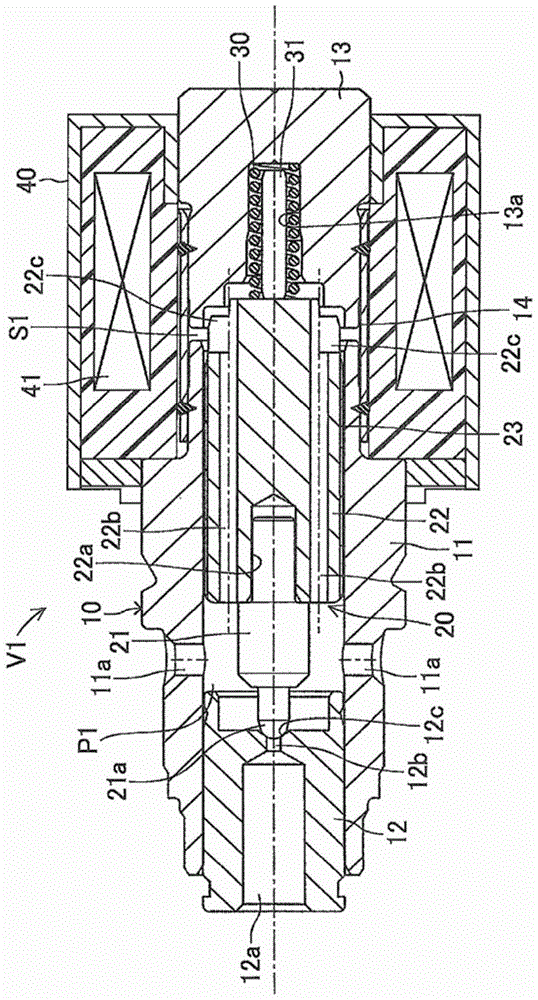

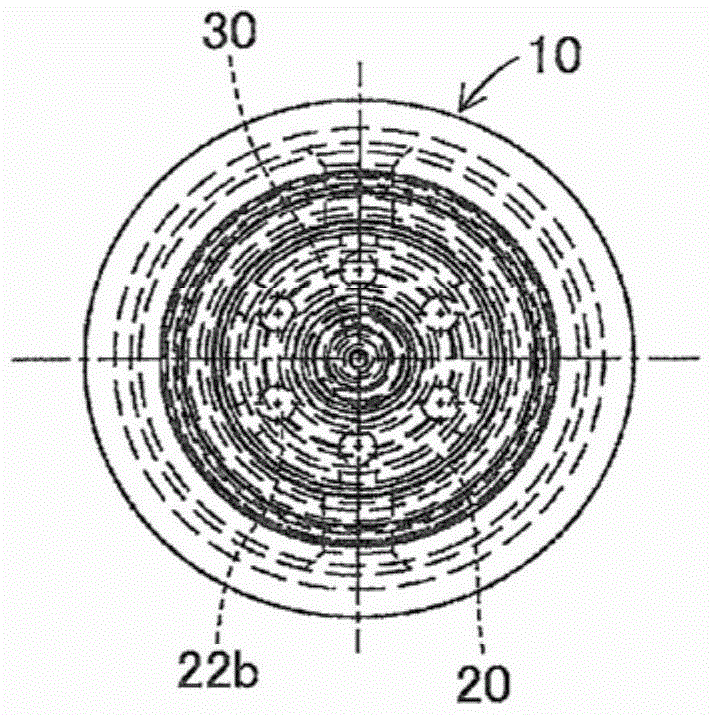

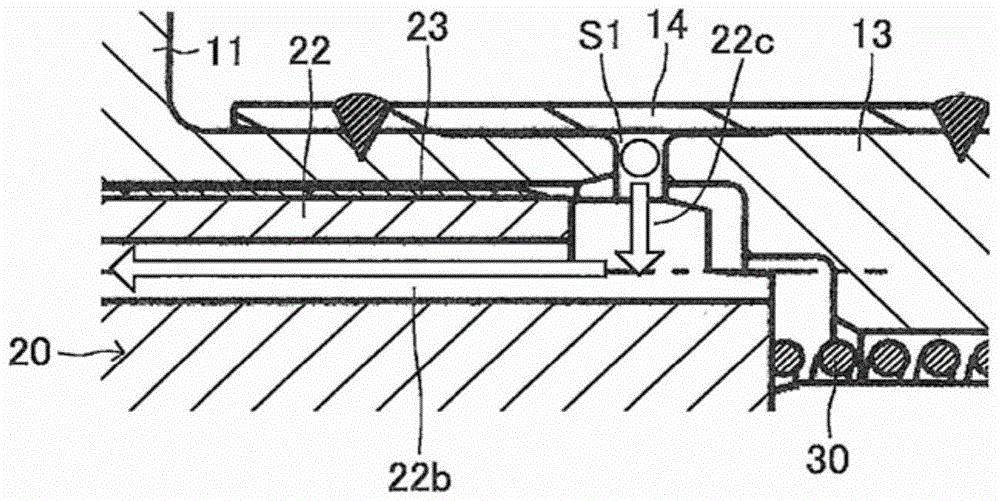

[0080] Embodiments of the present invention will be described below based on the drawings. Figure 1 ~ Figure 4 The first embodiment of the solenoid valve according to the present invention is shown. The solenoid valve V1 of this embodiment is, for example, a normally closed solenoid valve that is incorporated in a hydraulic control device of a hydraulic brake device for a vehicle and that is placed in the brake fluid. Used in hydraulic control. In addition, in this solenoid valve V1 , a plunger 20 , a spring 30 , a solenoid 40 , and the like are assembled in a case 10 .

[0081] The case 10 accommodates the plunger 20 , the spring 30 , etc. inside, and includes: a cylindrical guide member 11 that assists axial movement of the plunger 20 ; and a cylindrical seat member 12 . , the seat member 12 is fluid-tightly assembled to the guide member 11 so that its position can be adjusted in the axial direction. figure 1 The inner circumference of the left end. Furthermore, the hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com