Grommet

A grommet and ring-shaped technology, applied in the field of grommets, can solve the problem that the grommet cannot be assembled to the installation parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

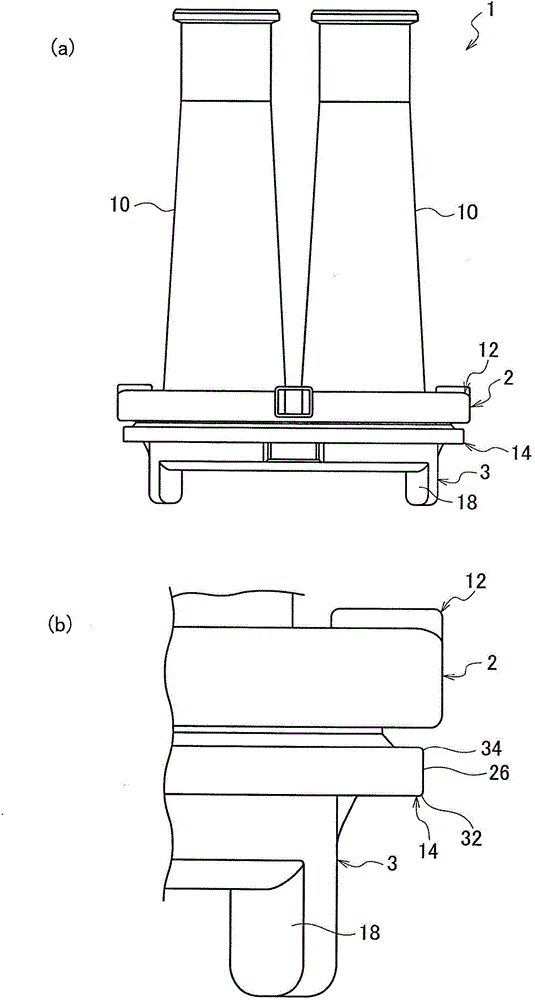

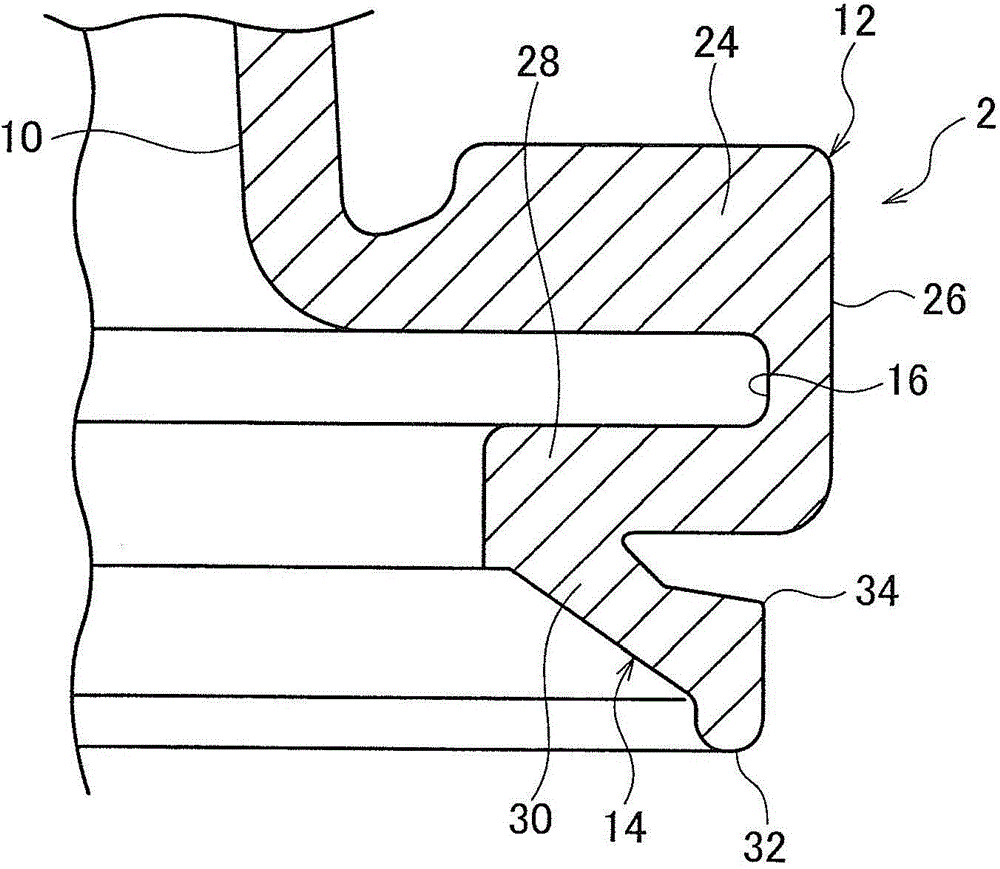

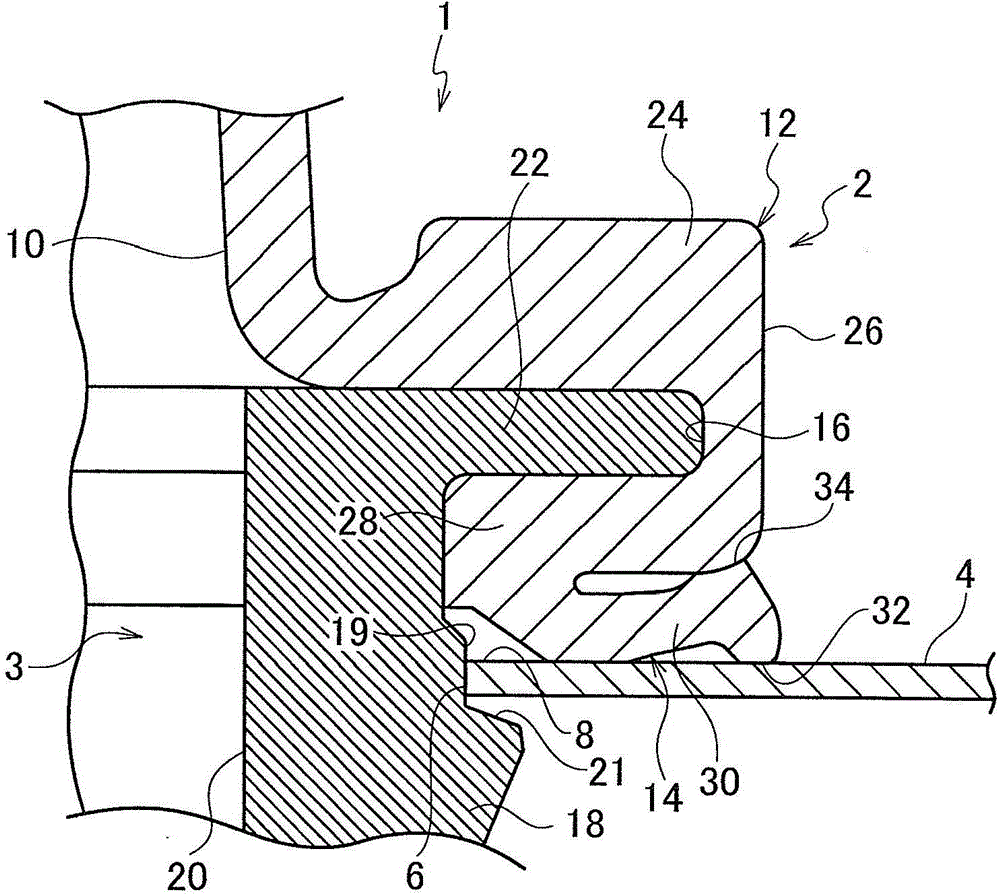

[0021] Such as figure 1 As shown in -3, the grommet 1 of the embodiment includes: a cylindrical inner grommet 3; Outer grommet2.

[0022] The outer grommet 2 includes: an electric wire insertion cylinder 10 formed integrally with soft material and through which electric wires are inserted; the flange portion 12; and the annular lip portion 14 extending from the flange portion 12 and closely abutting against the opening edge of the mounting hole 6.

[0023] The wire insertion tube 10 is formed with a plurality of (two in the embodiment) substantially cylindrical tubes. An elliptical flange portion 12 is formed on one end side of these cylindrical portions. These cylindrical portions are formed by reducing the diameter from the flange portion 12 side. In this way, the flange portion 12 is integrally formed with the wire insertion tube portion 10 .

[0024]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com