Mold laser adjusting scale

A laser and mold technology, applied in the field of adjusting ruler, can solve the problems of inability to see the adjustment degree, difficult to master, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

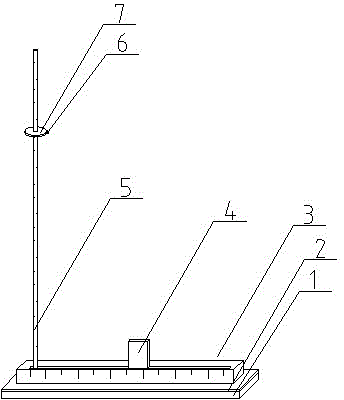

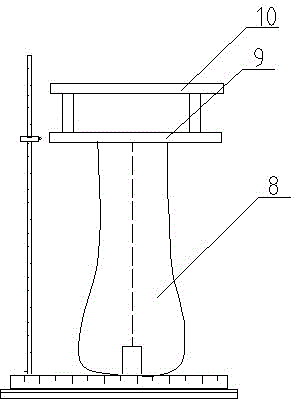

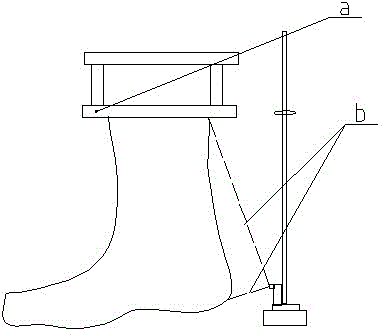

[0011] Such as figure 1 The shown mold laser calibration ruler includes a base 2 mounted on a magnetic base 1 . The magnetic base can be adsorbed to the surface of metal objects, stably ensuring accurate measurement results. The base 2 is provided with a support 3, the support 3 is a support with a horizontal scale, the upper surface of the support 3 is provided with a bar-shaped groove, and the centerline laser projector 4 is arranged in the bar-shaped groove through a slider, which is convenient Move the centerline laser projector to the centerline position of the iron foot mould, set a vertical scale bar 5 on the left end of the strip groove, and set a laser projection lamp on the vertical scale bar 5, and the laser head on the laser projection lamp is dot-shaped The laser head 6, the laser projection lamp is arranged on the vertical scale rod 5 through the slider 7, the middle of the slider is provided with a mounting hole matching with the vertical scale rod, and the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com