A control valve point riveting machine device for vacuum booster production line

A technology of vacuum booster and production line, which is applied to manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of poor spot riveting quality, low spot riveting efficiency, difficult spot riveting operation, etc., and achieves high qualification rate and spot riveting. The effect of convenient operation and easy pressing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

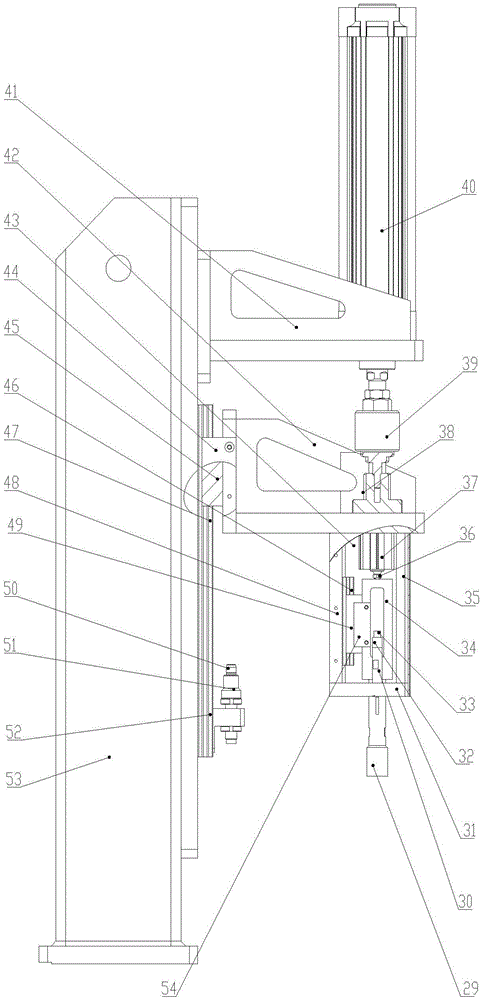

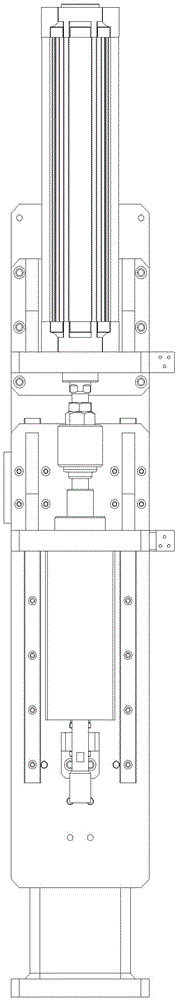

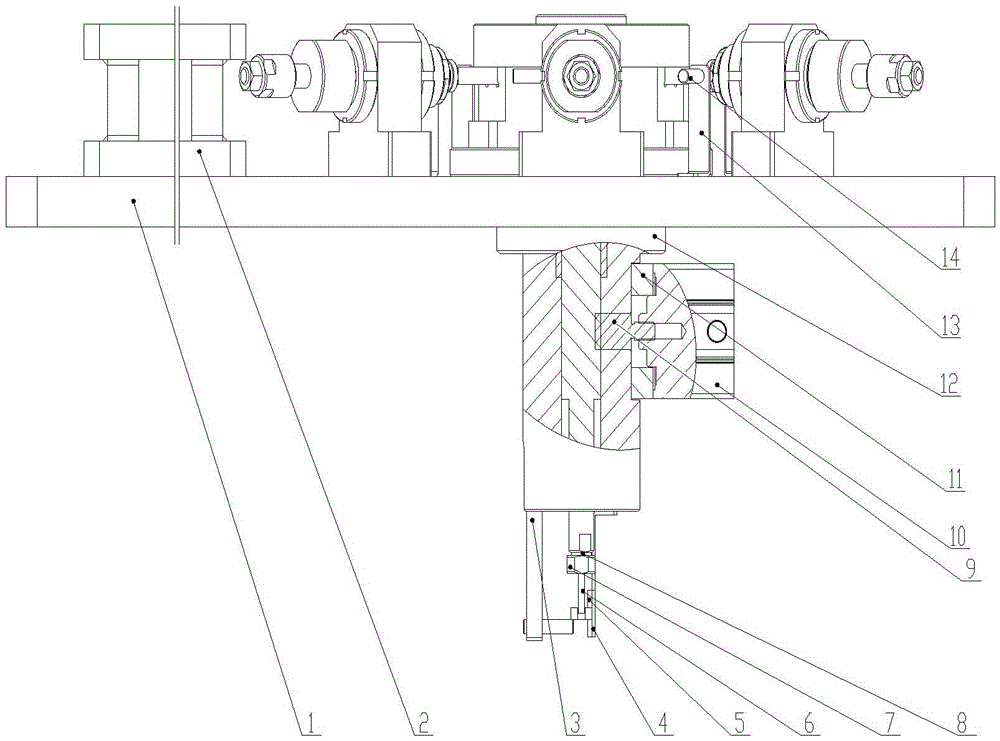

[0020] Reference attached figure 1 , attached figure 2 , a control valve point riveting machine device for a vacuum booster production line of the present invention, including a mounting base plate 1, a column seat 2 fixedly connected to the mounting base plate 1 and a riveting assembly, and a column 53 fixed to the column seat 2 Connected test fixture.

[0021] In this embodiment, the test fixture includes a first linear slide rail 47 connected to the column, a cylinder base 41 and a guide seat 42, the cylinder 40 is located above the cylinder base 41, and the guide base 42 is connected to the first linear slide rail 47 , can slide up and down along the first linear slide rail 47. A joint 38 and a floating joint 39 are respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com