Cam confirming device when camshaft is press-fitted

A technology for confirming devices and camshafts, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of unqualified press-fitting and low press-fitting efficiency, and achieve higher press-fitting pass rate and high accuracy of orientation determination , to meet the effect of high-efficiency assembly line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 is basically as follows:

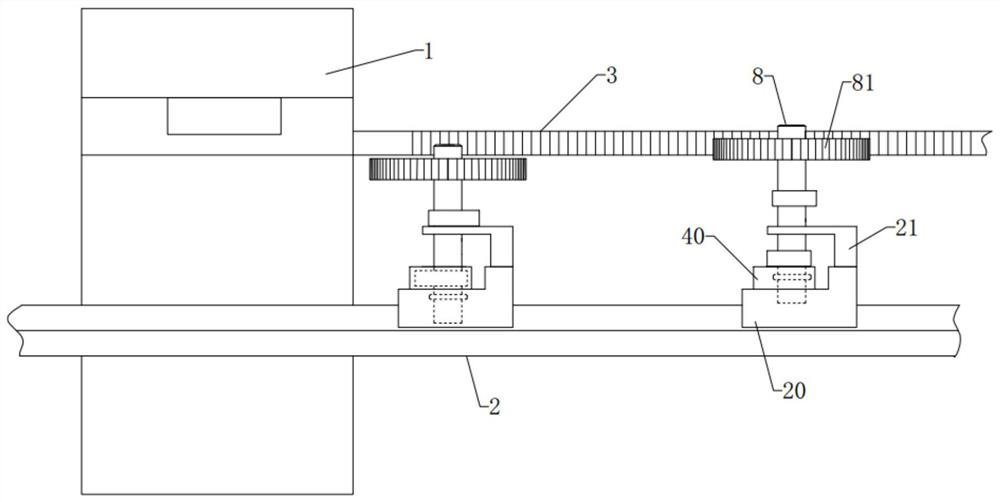

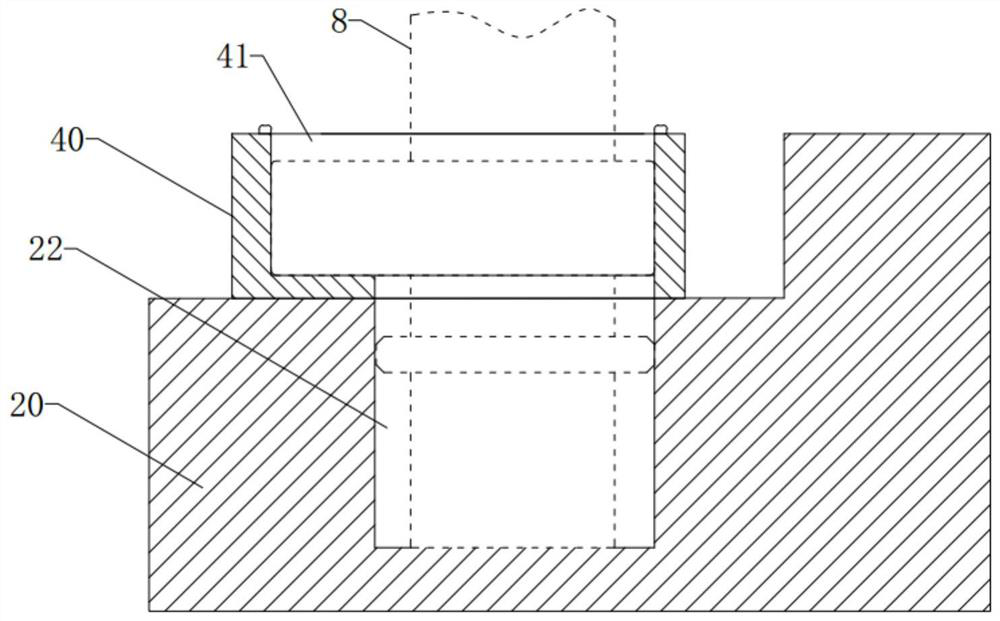

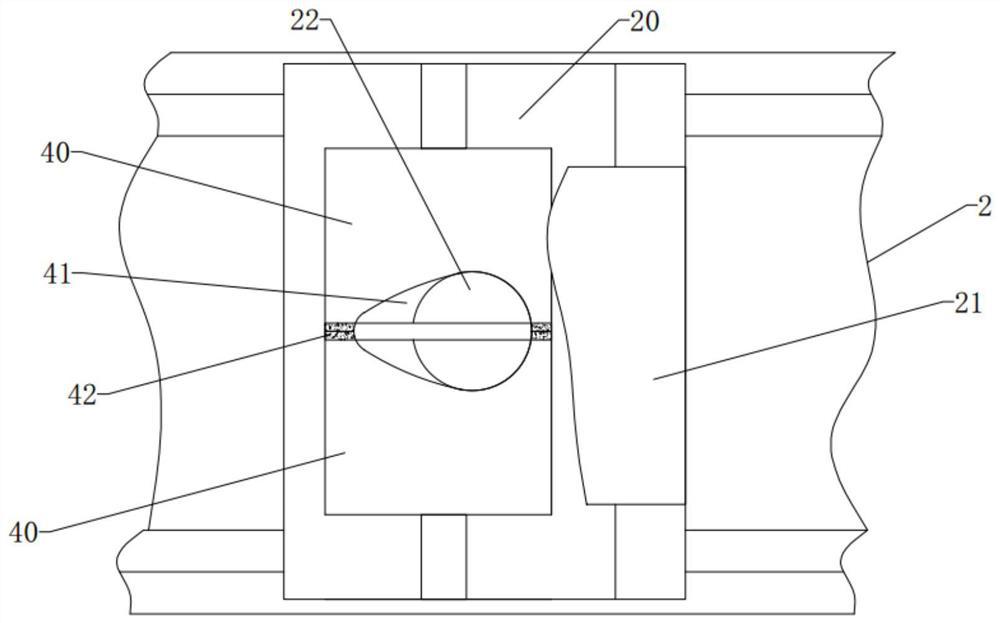

[0034] Cam confirming device when camshaft is press-fitted, such as figure 1 As shown, it includes the transmission mechanism 2 passing through the pressing machine 1. The transmission mechanism 2 in this embodiment specifically selects a chain conveyor belt, and the chain conveyor belt is fixedly connected with a moving seat 20 by bolts; The moving base 20 is slidably connected with the guide rail, and a motor driving mechanism for driving the moving base 20 to move toward the direction of the rail needs to be set on the moving base 20 . The movement of the moving seat 20 can send the camshaft 8 into the press-fitting machine 1 .

[0035] The top of the transmission mechanism 2 is provided with a rack 3 fixed to the press machine 1, and the rack 3 is parallel to the transmission direction of the transmission mechanism 2. When the camshaft 8 is transported by the moving seat 20, the gear plate 81 on the camshaft 8 is aligned wit...

Embodiment 2

[0042] The difference from Embodiment 1 is that, as Figure 5 As shown, the opening groove 23 has a matching portion matching the shape of the cam I82. The orientations of the cams I 82 on the camshaft 8 are perpendicular to each other, and the matching portion of the opening groove 23 can be used to cooperate with the cam I 82 that is closer to the gear plate 81 . In this way, the cam II 83 and the cam I 82 on the camshaft 8 are respectively aligned with the fitting groove 41 of the clamping block 40 and the matching portion of the opening groove 23, and the camshaft 8 will fall downward, thereby improving the accuracy of determining the direction of the cam II 83 and the cam I 82. sex.

Embodiment 3

[0044] The difference from Embodiment 1 and Embodiment 2 is that, as Image 6 As mentioned above, wedge-shaped blocks 6 are welded and fixed on the two clamping plates, and two fixed blocks 7 that can offset the wedge-shaped blocks 6 are welded and fixed on the press machine 1. Compatible inclined surfaces.

[0045] The moving seat 20 moves toward the press machine 1 with the camshaft 8, and the wedge block 6 is opposed to the fixed block 7, and the fixed block 7 can push the clamping plates close to each other through the wedge block 6, thereby clamping and fixing the camshaft 8. Compared with Embodiment 1 and Embodiment 2, power equipment such as motors and cylinders are not used, thereby reducing the cost of the device and reducing the wiring requirements of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com