Press-fitting process equipment of vehicle plate body assembly

A technology of process equipment and plate body, which is applied in the field of vehicles, can solve the problems of labor intensity not directly proportional to production capacity, labor-intensive production methods, easy deformation of plate pin rubber sleeves, etc., to achieve convenient and quick adjustment, ensure production progress, and reduce manpower. The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

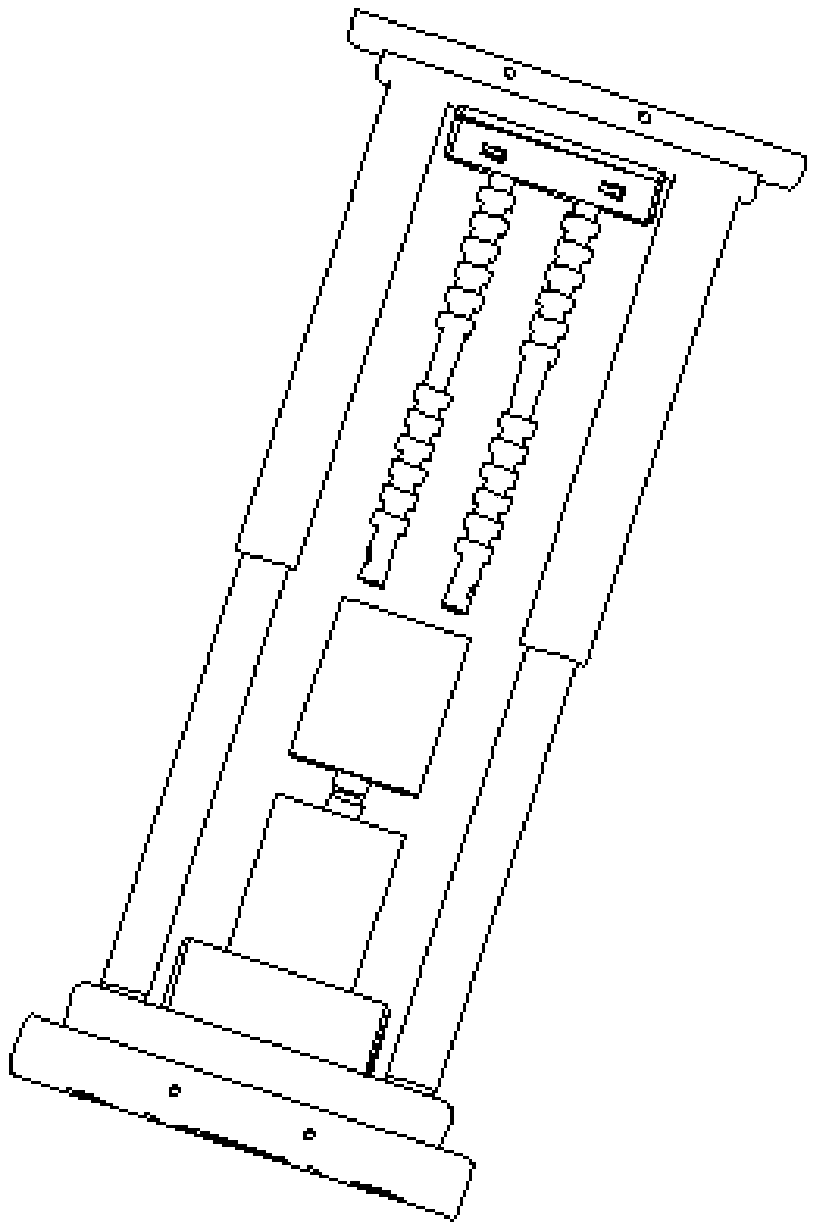

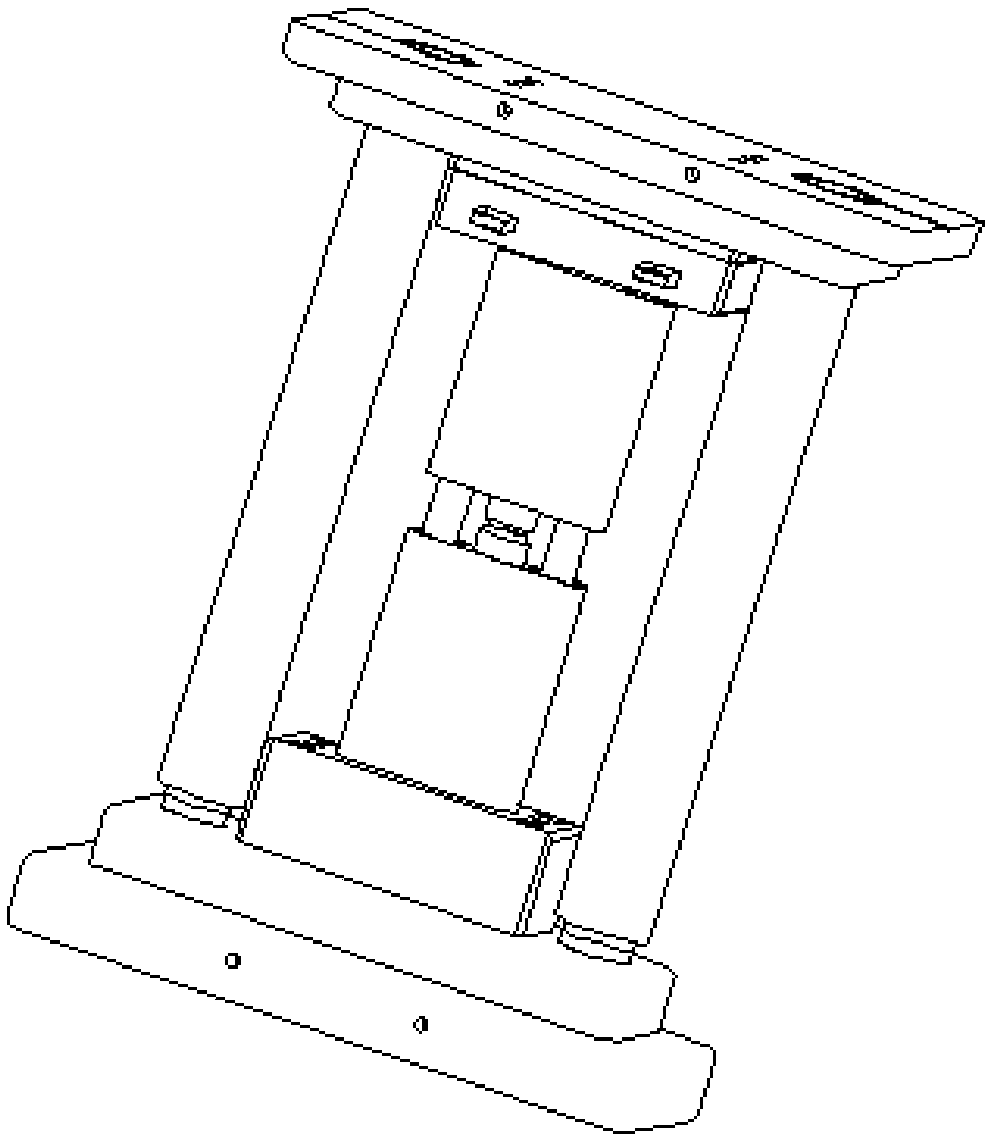

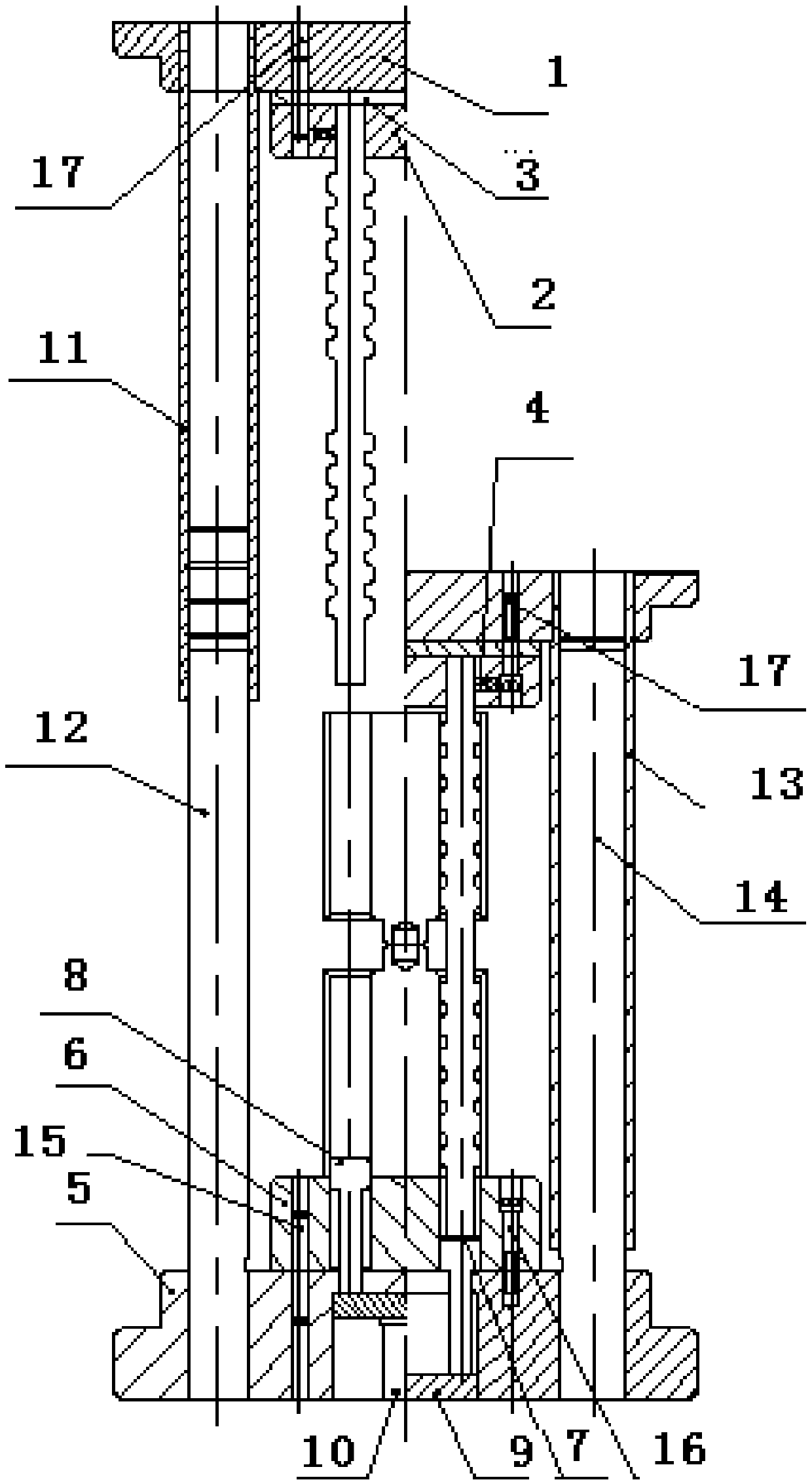

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] A press-fit process equipment for a vehicle panel body assembly, comprising a lower seat, a lower plate, an upper seat, an upper plate, a backing plate, a positioning plate, a left guide sleeve, a left guide post, a right guide sleeve, a right guide post, a pad, Ejector A, push plate, ejector B.

[0030] The backing plate is located between the upper seat and the upper plate, and the upper plate is fixed under the backing plate; the lower seat, the backing plate, and the lower plate are positioned by fixing pins and fixedly connected together with fastening screws.

[0031] The upper plate has pin holes in the vertical direction and upper plate positioning holes in the horizontal direction. The pin holes are used for inserting plate pins, and the positioning holes of the upper plate are used for inserting positioning blocks; the positioning holes of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com