Double-head stapler capable of aligning paper

A stapler and paper technology, which is applied in the direction of nailing U-shaped nail tools, nailing tools, manufacturing tools, etc., can solve the problems of inconvenient use, and achieve the effects of easy storage, small size, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

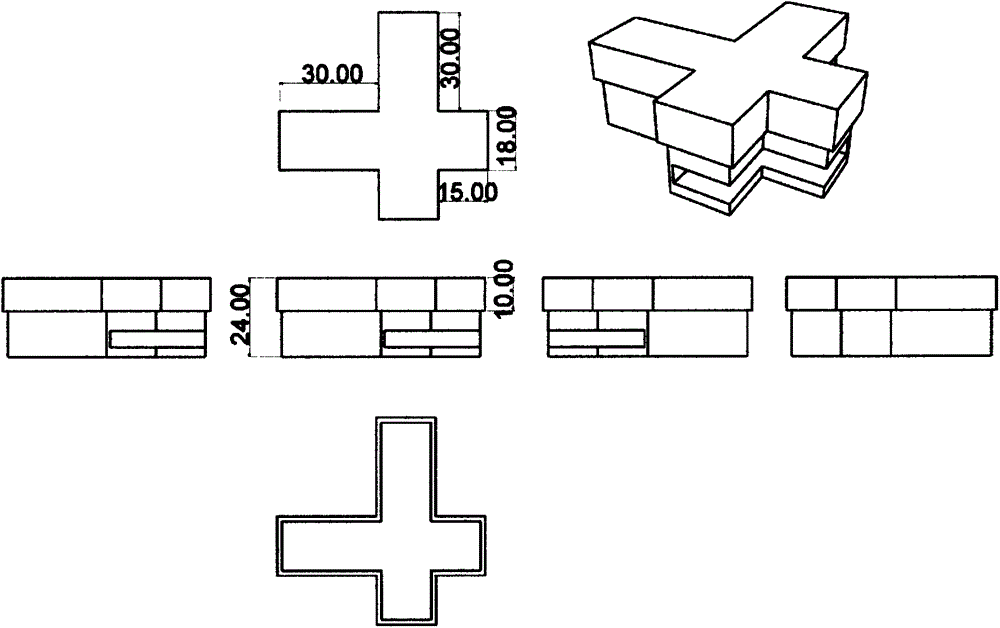

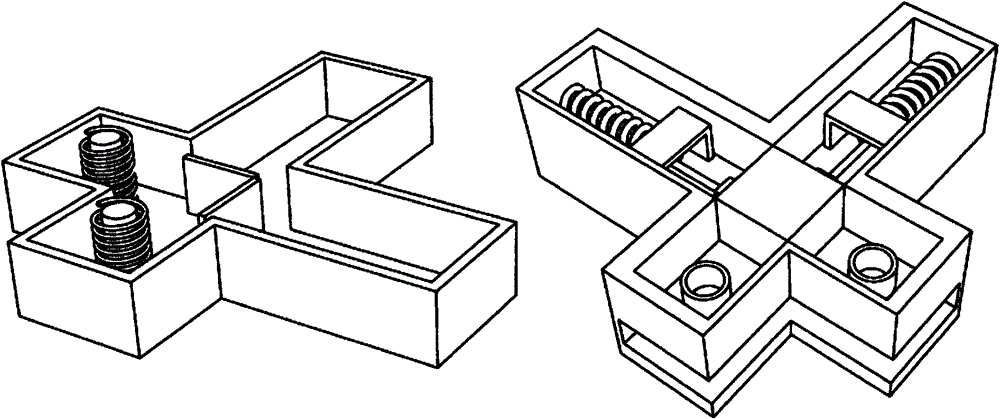

[0015] A double-headed binding and aligned paper stapler, which consists of an upper shell, two pressure plates, two large springs, a base, two nail storage slots, two push nail modules, two push nail springs, and a nail folding mold. Function To align the binding paper, two staples are nailed to the corner of the paper at right angles to prevent the corner from warping and abrasion. When using, first put the paper to be bound into the binding groove, and align it according to the limit, press the upper shell with the palm, make the pressure plate press down the two staples, and make the staple feet fold up according to the folding nail mold, the palm slowly Slowly loosen, the upper shell slowly rises under the action of the spring until it returns to its original shape. When replacing the staples, you only need to take off the upper shell and put the staples into the two staple storage slots respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com