Solid wood floor capable of preventing corners from tilting and production process thereof

A technology of solid wood flooring and corners, which is applied to wood processing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems that the floor is susceptible to moisture, affects the appearance and use, and the foundation is not well laid, so as to avoid the corners from warping , increase the service life, improve the effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

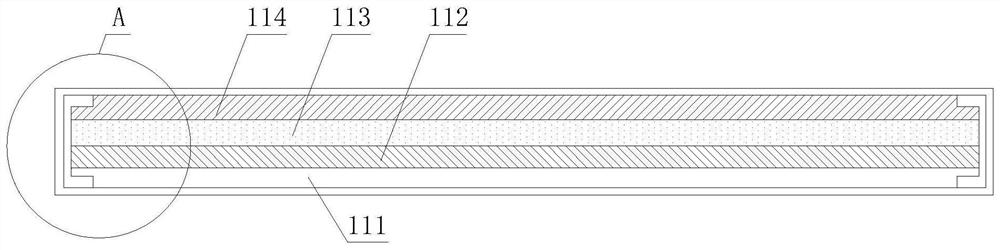

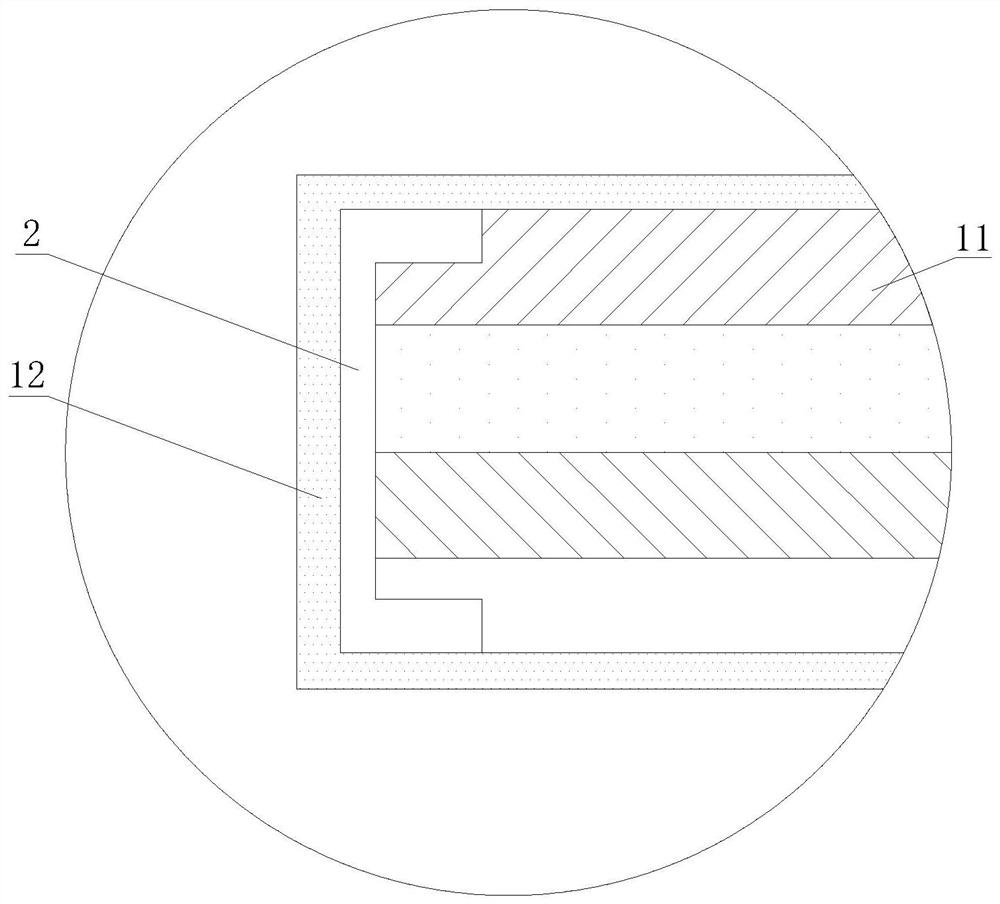

[0033] see Figure 1-3 , a kind of solid wood floor that prevents corners from warping, comprising a solid wood floor body 1, the solid wood floor body 1 includes a substrate layer 11 and an outer coating layer 12, and the substrate layer 11 includes an extruded layer 111, a bottom plate layer 112, a sound-absorbing layer 113 and The upper layer 114 is connected to the bottom layer 112 above the extruded layer 111, the sound-absorbing layer 113 is connected above the bottom layer 112, the upper layer 114 is connected above the sound-absorbing layer 113, and the outer coating layer 12 is coated on the outside of the substrate layer 11, and Fasteners 2 are arranged between the outer coating layer 12 and both sides of the substrate layer 11, the sound-absorbing layer 113, the bottom layer 112 and the upper layer 114 are bonded and connected by adhesive, and a layer is poured on the bottom layer 112. Extruded layer 111, extruded layer 111 is made of resin glue material, by coating...

Embodiment 2

[0046] In order to better demonstrate the production process of the solid wood floor that prevents the corners from warping, this embodiment proposes a production process of the solid wood floor that prevents the corners from warping, including the following steps:

[0047] Step 1: Timber pressing: Select solid wood plates as the material of the bottom layer 112 and the upper layer 114, apply adhesive on the joint surface of the bottom layer 112 and the upper layer 114, and heat the bottom layer 112, sound-absorbing layer 113 and The upper ply 114 is compacted;

[0048] Step 2: Surface processing: put the compacted sheet into a drying box for drying, take it out after drying for 7 minutes, put it into a mold, and pour a layer of resin glue on the bottom of the bottom layer 112 to make it The extruded layer 111 is cut into the desired shape after the surface is polished flat by a grinding device;

[0049] Step 3: Groove surface processing: Grind the two ends of the cut sheet t...

Embodiment 3

[0056] In order to better demonstrate the production process of the solid wood floor that prevents the corners from warping, this embodiment proposes a production process of the solid wood floor that prevents the corners from warping, including the following steps:

[0057] Step 1: Timber pressing: Select solid wood plates as the material of the bottom layer 112 and the upper layer 114, apply adhesive on the joint surface of the bottom layer 112 and the upper layer 114, and heat the bottom layer 112, sound-absorbing layer 113 and The upper ply 114 is compacted;

[0058] Step 2: Surface processing: put the compacted sheet into a drying box for drying, take it out after drying for 7 minutes, put it into a mold, and pour a layer of resin glue on the bottom of the bottom layer 112 to make it The extruded layer 111 is cut into the desired shape after the surface is polished flat by a grinding device;

[0059] Step 3: Groove surface processing: Grind the two ends of the cut sheet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com