The head three-way diversion device of the belt conveyor transfer station

A belt conveyor and diversion device technology, which is applied in the direction of conveyor objects, transportation and packaging, and slideway, can solve problems such as difficult maintenance and blockage, and achieve the effects of reducing equipment cost, convenient maintenance, and solving blockages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

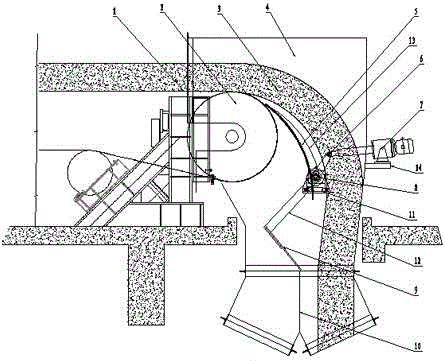

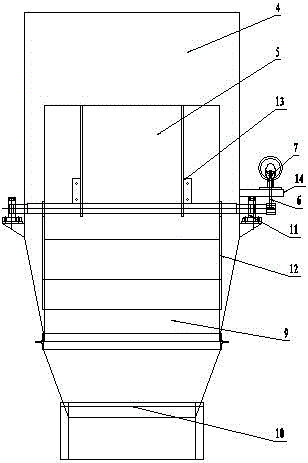

[0008] The head three-way diversion device of the belt conveyor transfer station of the present invention has a head drop hopper 4, and a deflector 5, an auxiliary deflector 9 and a three-way pipe 10 are installed in the head drop hopper 4, and in the drop hopper The outer wall of the middle part of 4 is fixed with an organic base 14, and the deflector driving device 7 is installed on the base 14. The deflector driving device 7 is an electric push rod or a power device that can drive the deflector 5 to generate displacement. 7 is connected with one end of the moment arm 6, and the other end of the moment arm 6 is connected with one end of the main shaft 8. The central part of the main shaft 8 in the cavity of the falling hopper 4 is welded with a deflector support frame 13, and the deflector 5 is connected with the deflector support frame 13. The main shaft 8 in the inner cavity of the hopper 4 is welded with the deflector 5 and the auxiliary bracket 12 at a certain angle, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com