A working method of a weaving tissue woven machine

A working method and technology of a knitting machine, which are applied in the directions of knitting, textile and paper making, and conveying filamentous materials, etc., can solve the problems of reducing production efficiency, deformation, broken goods, etc., so as to reduce labor costs, save labor costs, Satisfy the effect of long working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

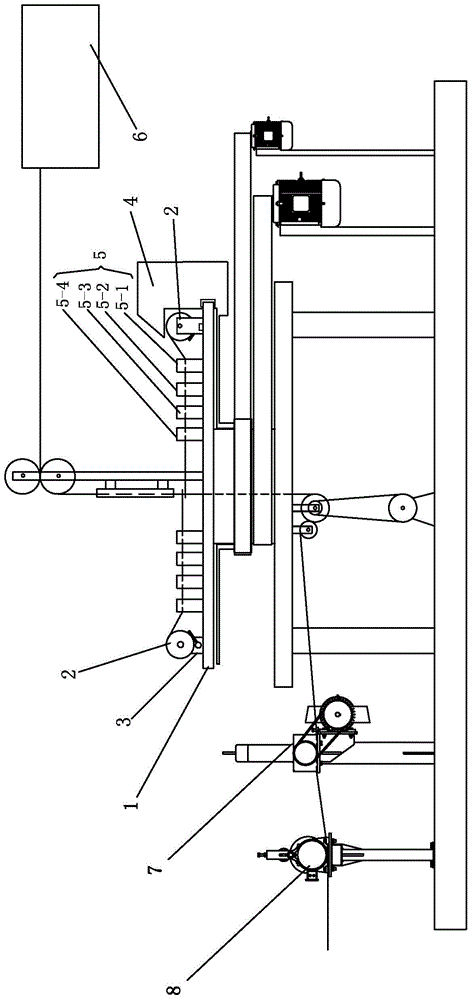

[0029] See Figure 1-Figure 3 with Image 6 , a kind of knitting machine for weaving net-shaped tie bars, comprising:

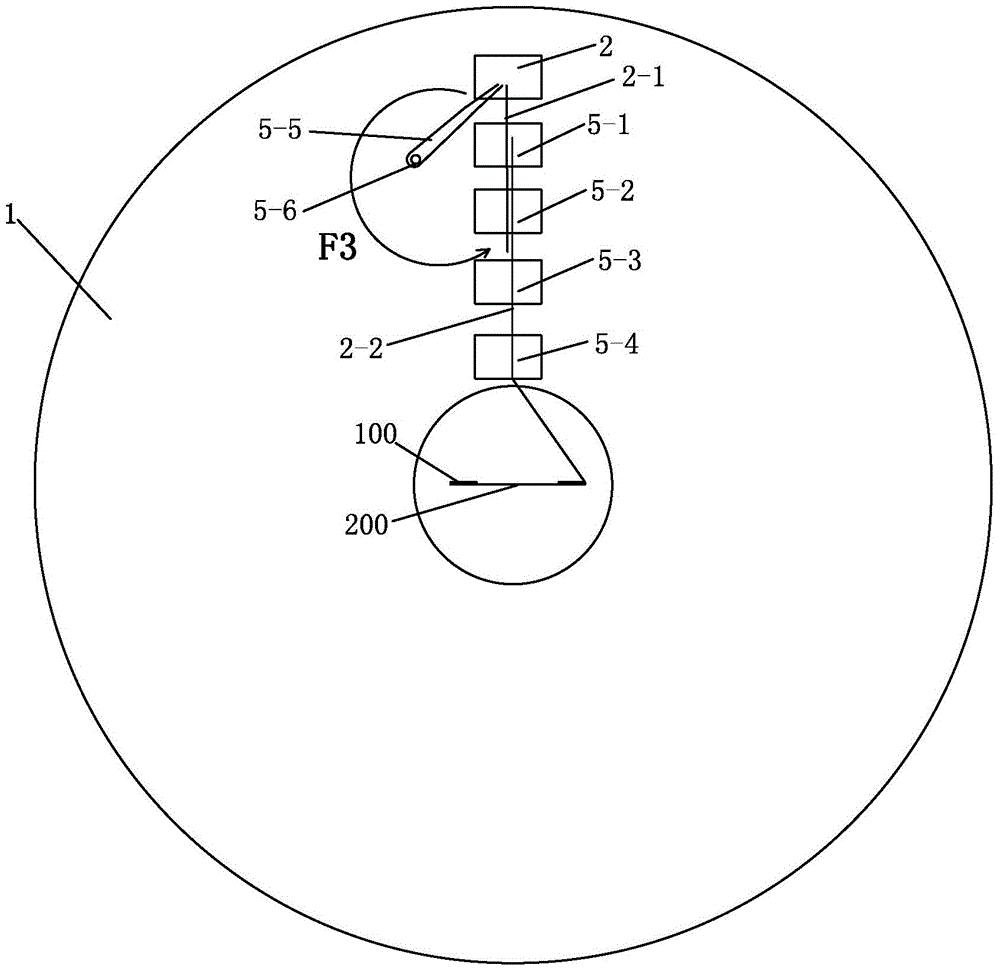

[0030] A winding system, the winding system includes: a spindle turntable 1, on which at least two spindle stations for placing spindles 2 are arranged; the spindle turntable 1 is suitable for rotating the yarn output from each spindle station as a secondary The reinforcement strips 200 are evenly distributed and wrapped around the two parallel main reinforcement strips 100 .

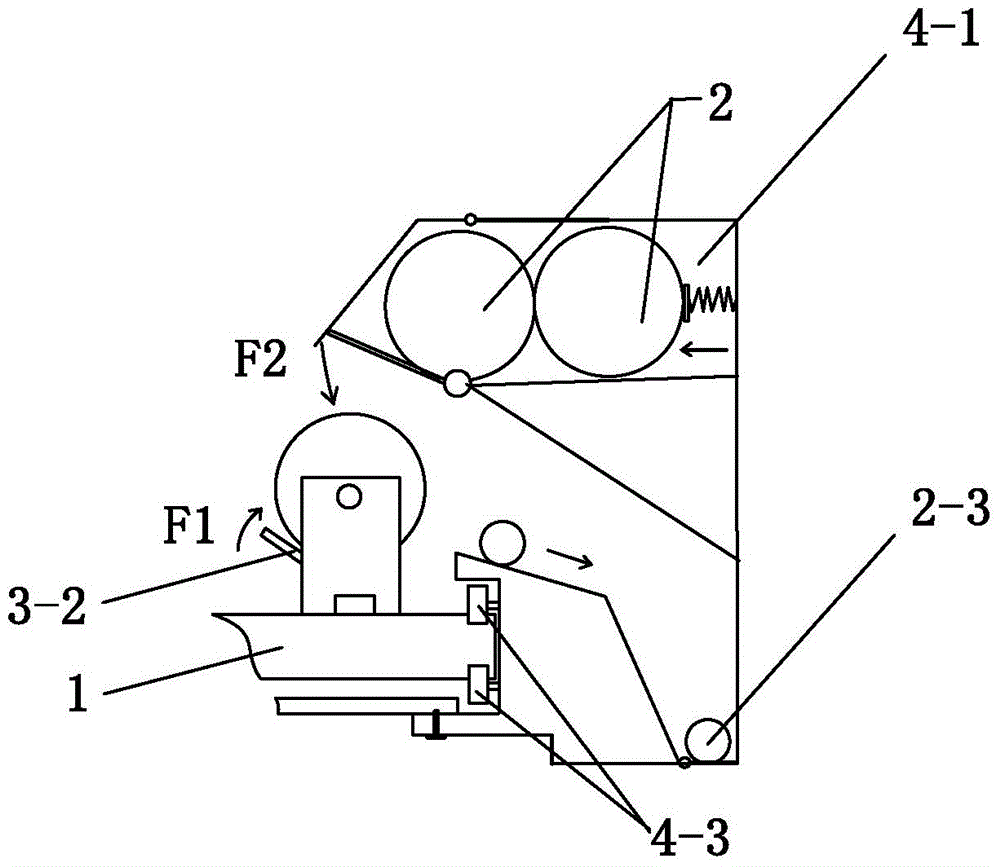

[0031] See image 3 with Figure 4 , the spindle station is provided with a sensor for detecting whether the unwinding of the spindle is complete; and a spindle frame suitable for removing the spindle bobbin 2-3 after detecting that the spindle 2 is unwinded.

[0032] The specific embodiment of the spindle frame, the spindle frame includes: a creel 3 suitable for clamping the spindle 2; Describe the baffle plate 3-1 of the spindle bobbin.

[0033] When replacing the spindle, the ...

Embodiment 2

[0061] A kind of working method of the knitting machine for weaving the mesh tie bar on the basis of embodiment 1, wherein, the knitting machine comprises:

[0062] A winding system, the winding system includes: a spindle turntable 1, on which at least two spindle stations for placing spindles 2 are arranged; the spindle turntable 1 is suitable for rotating the yarn output from each spindle station as a secondary The reinforcement strips 200 are surrounded and evenly distributed on the two main reinforcement strips 100 parallel to each other.

[0063]The spindle station is provided with a sensor for detecting whether the spindle has been completely unwound; and a spindle frame suitable for removing the spindle bobbin after detecting that the spindle is completely unwound.

[0064] And, the spindle changing mechanism 4 and the yarn connecting mechanism 5 located on the spindle rotating disk 1 .

[0065] The working method of described knitting machine comprises:

[0066] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com