Method for producing aromatic substances by Trichoderma reesei

A technology of Trichoderma reesei and fermentation substrate, applied in the field of producing beta-phenylethanol and/or phenylacetaldehyde, can solve the problems of expensive L-phenylalanine raw material, limited initial raw material of phenylethanol, and high fermentation cost , to achieve the effect of shortening production time, non-toxic growth, and diversifying metabolic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

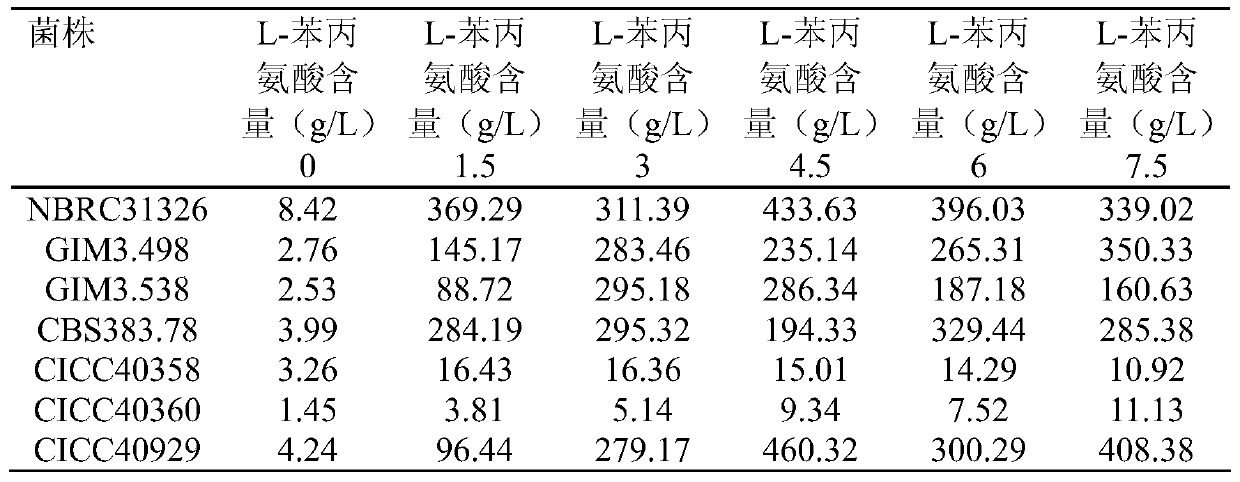

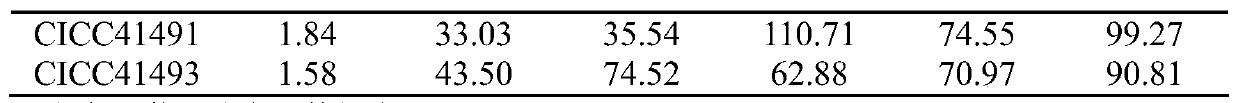

[0037] Example 1 Trichoderma reesei utilizes bran to produce β-phenylethanol

[0038] Fermentation medium (g / L): bran 60 (Yihai Kerry (Kunshan) Food Industry Co., Ltd.), glucose 1, ammonium sulfate 1.84, yeast extract 0.5 (OXOID, product number LP0021), potassium dihydrogen phosphate 0.2, Magnesium sulfate heptahydrate 0.5, calcium chloride dihydrate 0.03, L-phenylalanine added at 0, 1.5, 3, 4.5, 6 and 7.5 g / L, pH natural.

[0039] The above medium was divided into 250mL shake flasks, 50ml per bottle, and sterilized at 115°C for 20min.

[0040] Strain cultivation: inoculate the spores of nine kinds of Trichoderma reesei in Table 1 on PDA medium respectively, and culture them at 28° C. for 7 days. PDA medium formula: boil 200g potatoes for half an hour, filter through 4 layers of gauze, and make 1 liter. After sterilization at 115°C, add 20 g of glucose.

[0041] Preparation of spore suspension: the Trichoderma reesei strains cultured on the PDA culture plate for 7 days we...

Embodiment 2

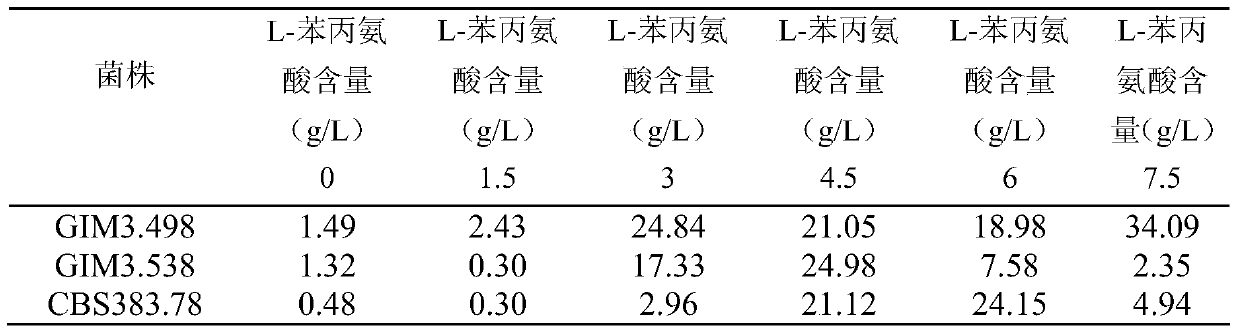

[0050] Example 2 Trichoderma reesei utilizes defatted rice bran meal to produce β-phenylethanol

[0051] In order to further investigate the effect of using other cheap carbon sources to cultivate Trichoderma reesei to produce β-phenylethanol, randomly selected strains GIM3.498, GIM3.538, and CBS383.78 were fermented on the medium with defatted rice bran meal as the carbon source.

[0052] Fermentation medium (g / L): defatted rice bran meal 60 (Yihai Kerry (Jiamusi) Grain and Oil Industry Co., Ltd.), glucose 1, ammonium sulfate 1.84, yeast extract (OXOID, product number LP0021) 0.5, potassium dihydrogen phosphate 0.2 , magnesium sulfate heptahydrate 0.5, calcium chloride dihydrate 0.03, L-phenylalanine addition 0, 1.5, 3, 4.5, 6 and 7.5, pH natural.

[0053] The above medium was divided into 250mL shake flasks, 50mL per shake flask, and sterilized at 115°C for 20min.

[0054] The experimental method is the same as in Example 1, except that the culture medium used is different....

Embodiment 3

[0062] Example 3 Fermentation in 7.5L and 30L fermenters using fermentation strain CICC40929

[0063] In combination with Examples 1-2, we proved that CICC40929, BRC31326, GIM3.498, GIM3.538, CBS383.78, CICC40358, CICC40360, CICC41491, and CICC41493 can produce β-phenylethanol at the shake flask level. Through Example 3, we further verified the ability of the Trichoderma reesei strain to produce phenylethanol at the fermenter level, wherein CICC40929 was randomly selected for fermentation in a 7.5-liter tank and a 30-liter tank, respectively. For the 7.5 liter fermenter experiment, the main carbon source used was bran; the 30 liter fermenter used glucose as the carbon source.

[0064] (1) Fermentation of CICC40929 in 7.5L tank

[0065] Fermentation medium

[0066] Fermented seed medium (g / L): malt extract 20, glucose 20, ammonium sulfate 1.84, yeast extract 0.5, potassium dihydrogen phosphate 0.2, magnesium sulfate heptahydrate 0.5, calcium chloride dihydrate 0.03, pH natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com