Method for type selection of short-wall mining working face equipment of continuous miner

A technology for equipment selection and shearer, which is applied in the directions of surface mining, earthwork drilling, underground mining, etc., can solve the blank of equipment selection method, and cannot guide the short-wall mining work of continuous shearer quickly, accurately and standardizedly. equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

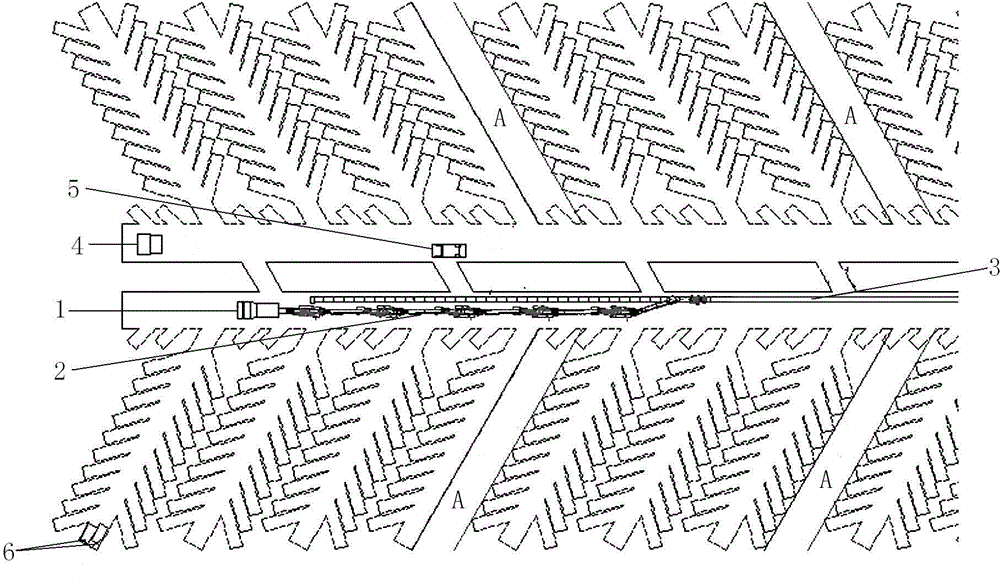

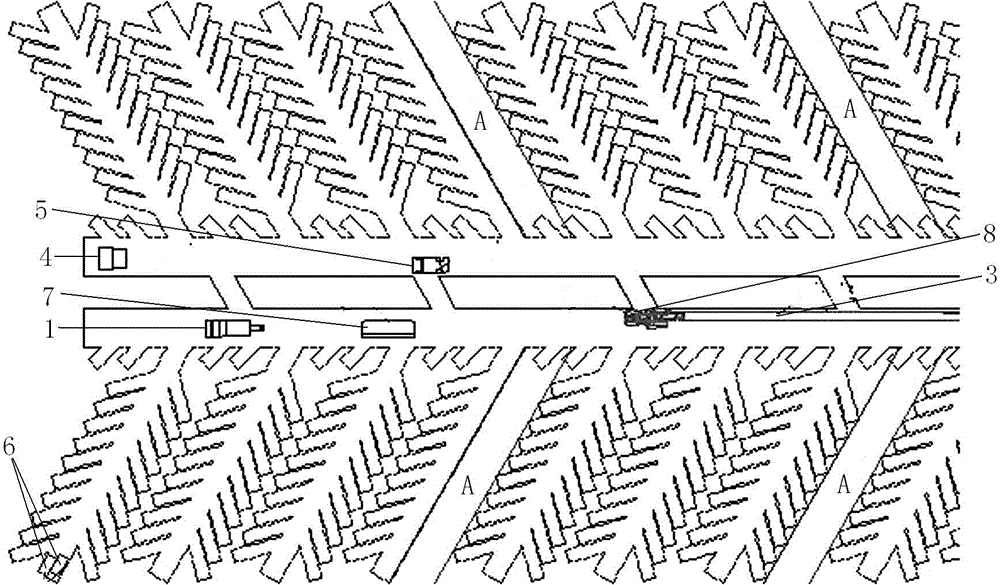

[0018] A type selection method for continuous coal miner short-wall mining equipment, the equipment used in the method includes continuous coal miner, transfer equipment, support equipment, feeding and crushing equipment, roadway cleaning and auxiliary equipment, and other supporting equipment; For the short-wall mining face of the continuous coal mining machine, the continuous coal mining machine in the head-on mining link, the crawler scraper type continuous transport system in the subsequent transfer link, the rubber wheel transport equipment, the support equipment in the process of tunneling and mining, After the rubber-wheeled transportation equipment, it is used for feeding and crushing equipment for large coal crushing, for roadway floating coal cleaning and material auxiliary transportation equipment, and for the complete set of equipment for ventilation, drainage, power supply, protection, lighting and other auxiliary equipment. Proceed as follows:

[0019] (1) Accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com