Conveying device and conveying method of sample container

A technology of sample container and conveying device, applied in the direction of instruments, analytical materials, etc., can solve the problems of backlog, low efficiency, traffic jam, etc., and achieve the effect of high conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

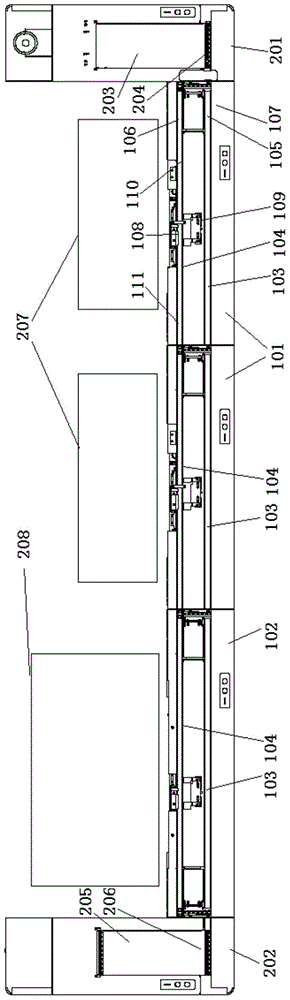

[0012] An implementation of the sample container transport device of the present invention can be referred to figure 1 , including a loading module 201 , an unloading module 202 and a track module 101 . In this embodiment, the track module 101 track module includes an inner track (104), an outer track (103) and a track changing area, and the track changing area is provided with a track changing mechanism for placing the sample container between the inner track and the outer track. Change the track, the inner track includes the analysis area (108), specifically the structure in Embodiment 2 can be used, of course, in other implementation manners, various deformed structures can also be used.

[0013] The loading module 201 has a loading area 203 for storing the sample containers 100 and an ejection channel 204 communicating with the loading area. The unloading module 202 has an unloading area 205 for storing the sample containers and a receiving channel 206 communicating with t...

Embodiment 2

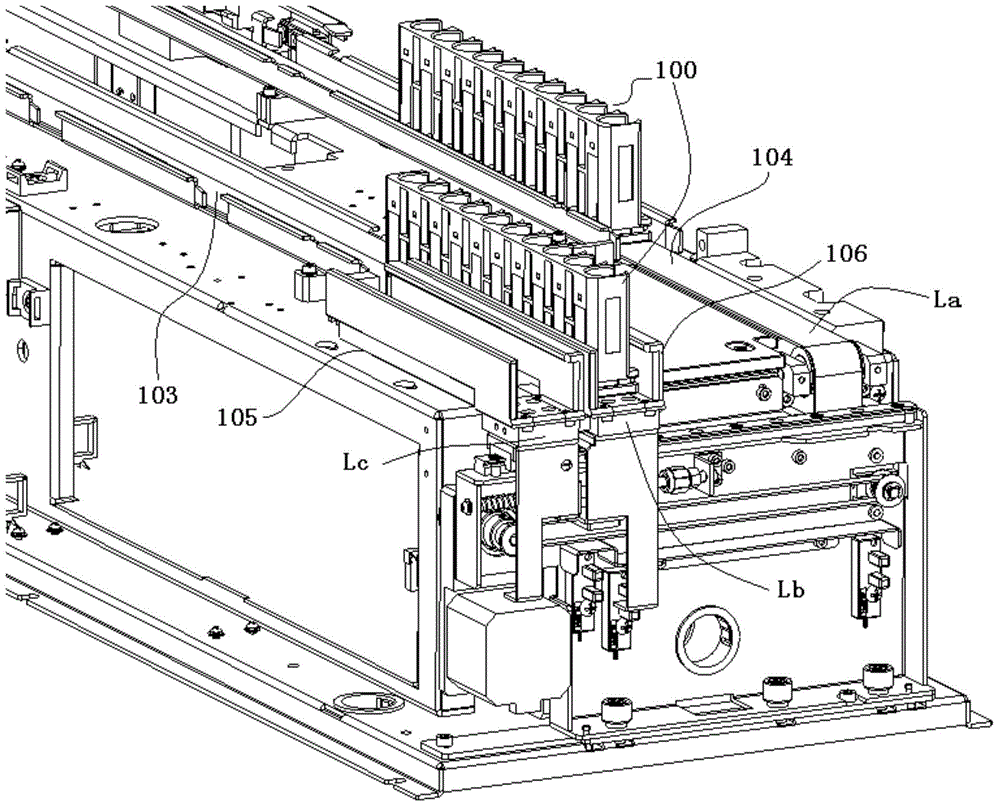

[0025] The track changing mechanism in the conveying device of the present invention may be a finger track changing mechanism, which is specifically described as follows.

[0026] refer to figure 2 , the claw track change mechanism includes an outer claw 105 and an inner claw 106 parallel to the track, and an outer claw stay area 107 outside the outer track (for clarity, figure 1Only one track module is marked with the labels of the various parts of the claw track change mechanism, and the rest of the track modules are not marked), and the outer claw stay area 107 can be concealed in the housing of the track module. Each finger includes two side walls 1101 that can move along the direction perpendicular to the track. When the finger is on the track, the side walls of the finger constitute the track side wall of the track. When the inner finger moves to the outer track , the outer claw originally located on the outer track moves to the rest area of the outer claw. In other...

Embodiment 3

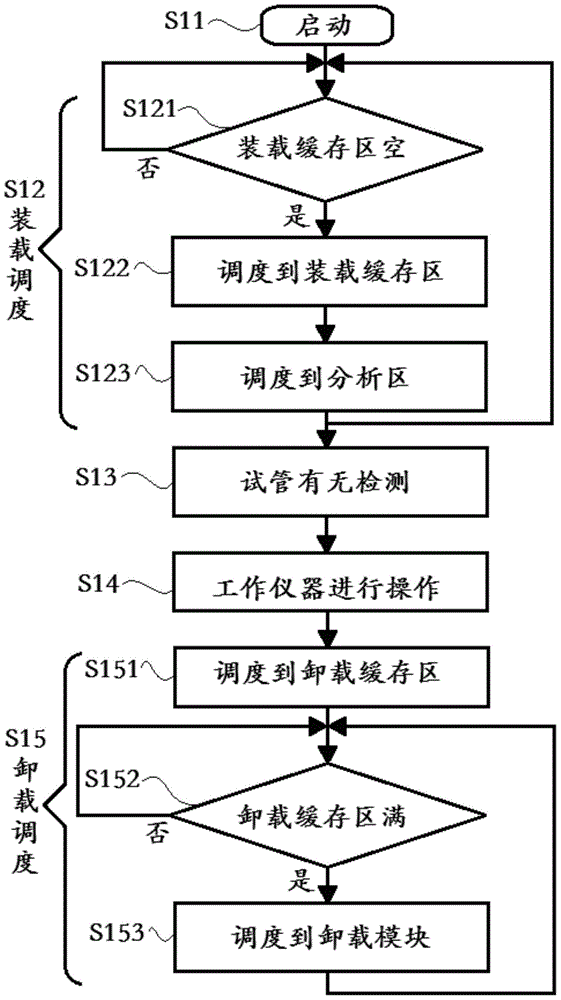

[0029] refer to image 3 , the transporting method of sample container of the present invention, adopts the transporting device among the embodiment 1, and method comprises the following steps:

[0030] S11. Start: Obtain a start command of the pipeline. The so-called start instruction can be an instruction issued by the user through a software operation interface or a hardware button, or an instruction automatically generated by the loading module after detecting that the loading area is loaded with a sample container through an automatic detection device.

[0031] S12. Loading scheduling: control the transmission mechanism on the track and the track change operation of the track change area, and dispatch the sample container pushed out by the loading module to the analysis area where the working instrument needs to be used. Among them, the control track change mechanism does not need track change Align the outer track when operating. In the case that the inner track of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com