High-speed rail sand table train control system

A train control system and sand table technology, applied in instruments, simulators, space navigation equipment, etc., can solve problems such as affecting the quality of practical training and teaching in railway colleges and universities, unfavorable students' skills, and inability to meet the needs of teaching in terms of practical effects. The effect of locomotive signal lighting control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

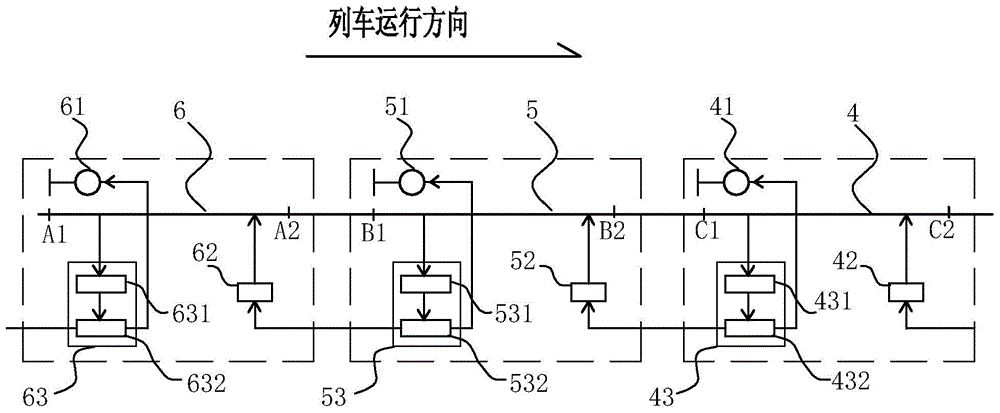

[0051] A sand table train control system for high-speed rail, including a simulated track and a simulated train, the simulated track includes three track sections: track section 6 between A1 and A2, track section 5 between B1 and B2, and track section 5 between C1 and B2. Between C2 is the track section 4, and train control devices and ground signals are installed in each track section;

[0052] The train control devices have the same structure, including a frequency-shifting signal transmitter and a frequency-shifting signal receiver, namely:

[0053] Ground signal machine 41, frequency-shifting signal transmitter 42 and frequency-shifting signal receiver 43 are arranged in track section 4, and frequency-shifting signal transmitter 42 and frequency-shifting signal receiver 43 are installed at the two ends of track section 4 respectively;

[0054] The input end of the frequency-shifting signal receiver 43 is connected with the analog track through a transmission line,

[0055...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com