A front rubber core structure for usb connector

A front rubber core and connector technology, which is applied to the parts of the connection device, computer peripheral equipment connectors, connections, etc., can solve the problems of unguaranteed installation quality, easy loosening of ground shrapnel, and complicated installation process, etc., to achieve The male-female mating is stable, the installation is firm, and the effect of improving the installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

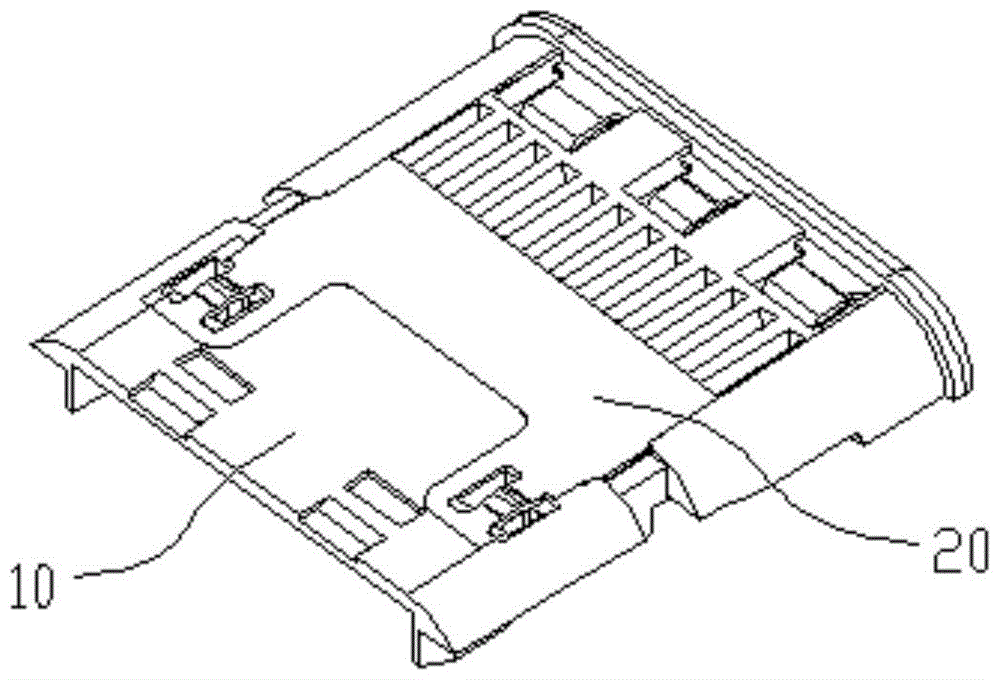

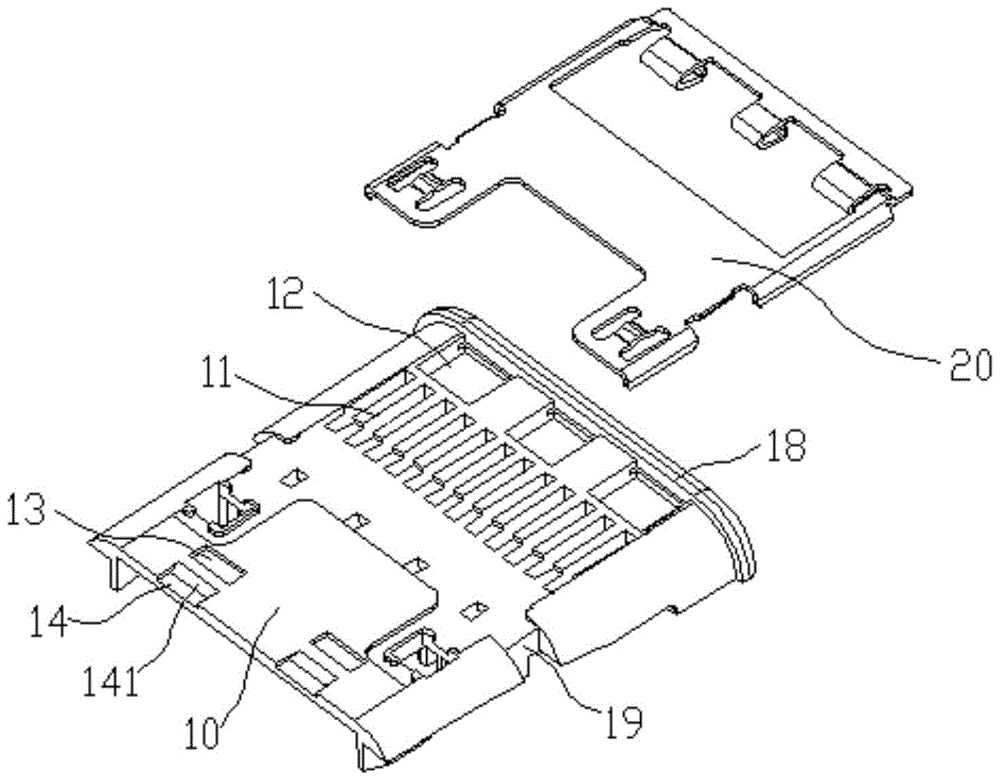

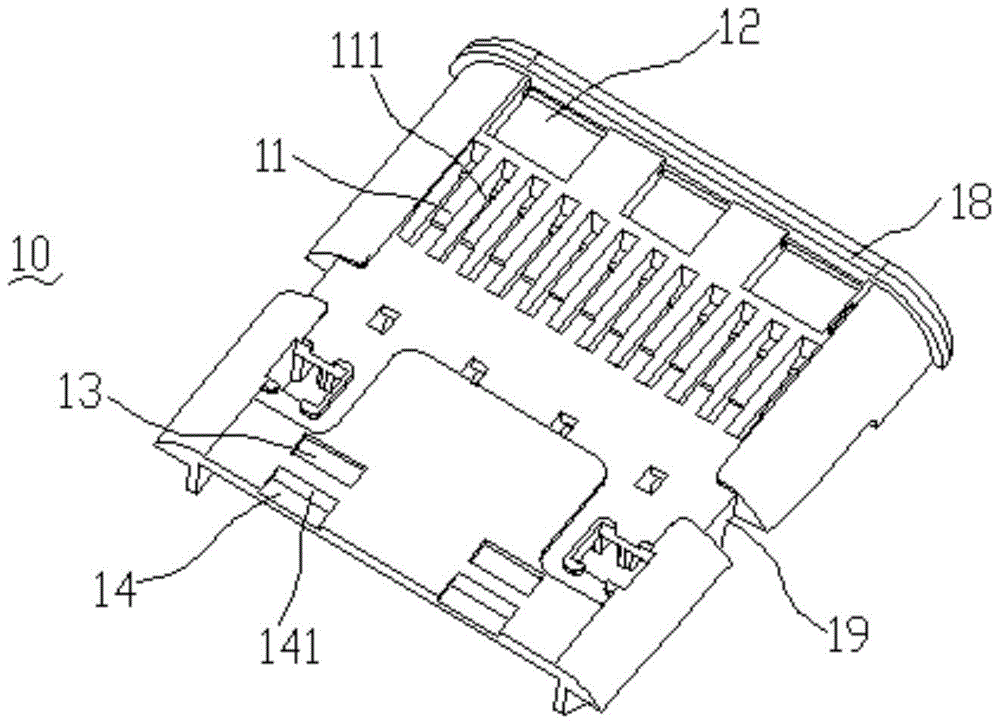

[0034] See figure 1 and figure 2 As shown, a front rubber core structure for a USB connector includes: a front rubber core body 10 and a grounding spring plate 20 fixedly arranged on the front rubber core body 10, and the grounding spring plate 20 is injected with plastic It is fixed on the front rubber core body 10 .

[0035] See Figure 4 and Figure 7 As shown, a number of ribs 11 are uniformly arranged on the inner side of the front rubber core body 10 , accommodating grooves 111 are formed between the ribs 11 , and terminals 30 are inserted in the accommodating grooves 111 . A protrusion 112 is fixedly arranged on the rib 11 , and the protrusion 112 abuts against the position-limiting end surface 41 of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com