Processing method and mold of ring-type diamond composite wear-resistant belt

A technology of composite materials and processing methods, which is applied in the processing method of ring-type diamond composite wear-resistant belt and the field of molds, can solve the problems of sleeve wear, inconsistent wear of polycrystalline diamond, and chaotic diamond arrangement, so as to improve processing quality and efficiency, reduce processing costs, and optimize the effect of orderly arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

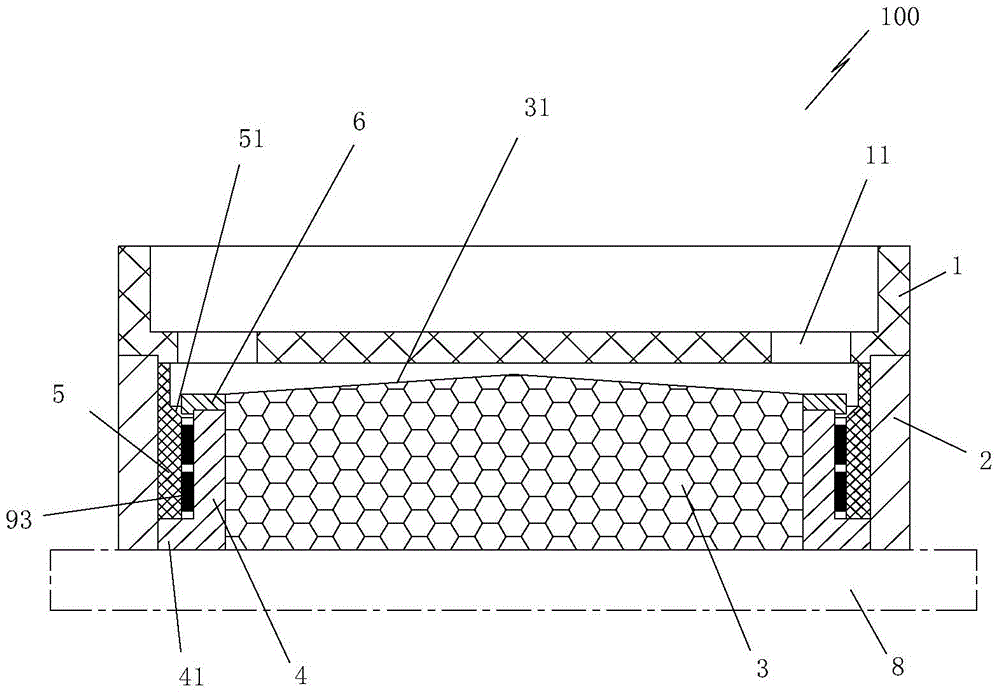

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

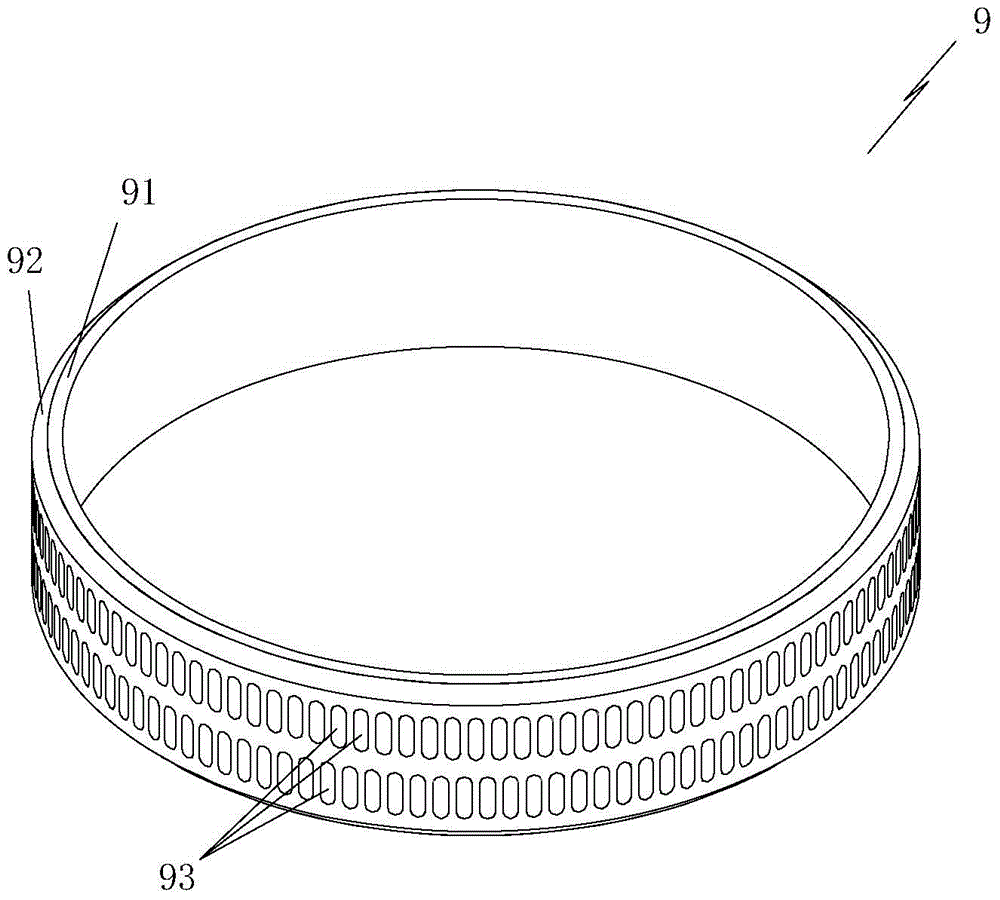

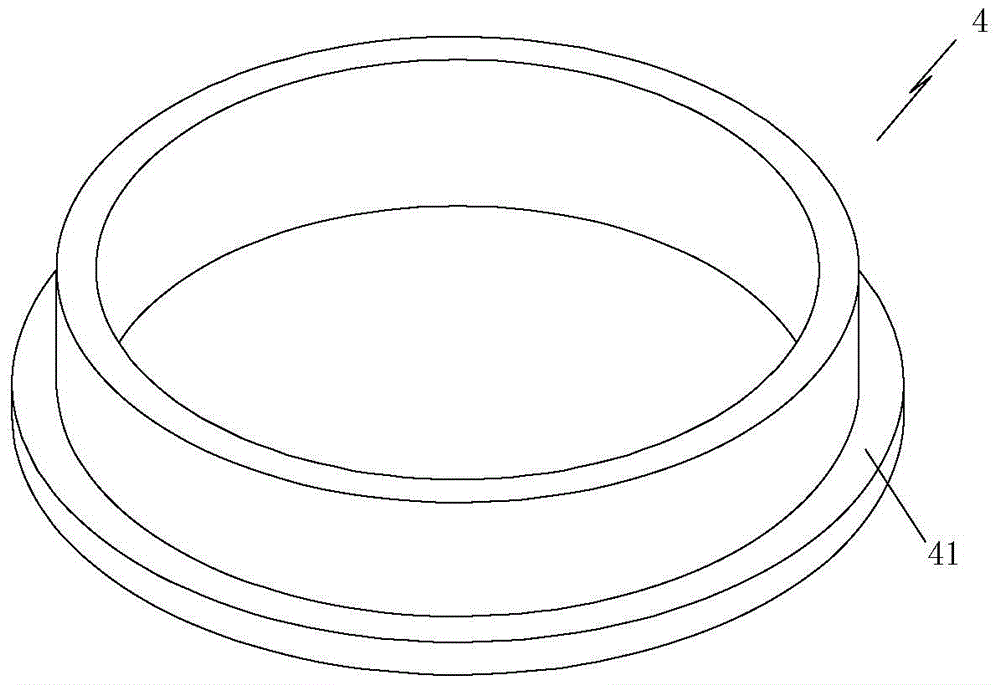

[0040] Such as figure 1 Shown, is the wear-resistant belt 9 that adopts the processing method of ring-type diamond composite material wear-resistant belt of the present invention to make, and this wear-resistant belt 9 is ring-shaped, is made of steel substrate 91, wear-resistant base material layer 92 and steel lining The outer surface of the bottom 91 is composed of a plurality of massive polycrystalline diamonds 93 arranged in an orderly manner; this anti-wear belt 9 not only has extremely strong wear resistance, but also can enhance the wear resistance of the drill pipe joint. At the same time, the friction coefficient is small, and the friction The resistance is low, the wear ability to the casing is weak, and the casing has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com