Impact type high-speed weft cutting device

An impact-type, high-speed technology, applied in textiles, textiles, papermaking, looms, etc., can solve problems affecting the beating speed and quality, unbalanced force, easy damage, etc., and achieve energy utilization rate improvement, shear force big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

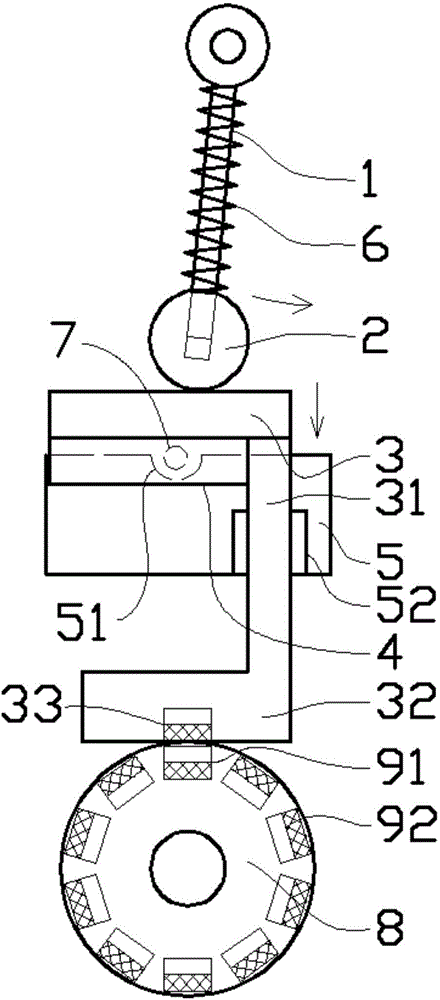

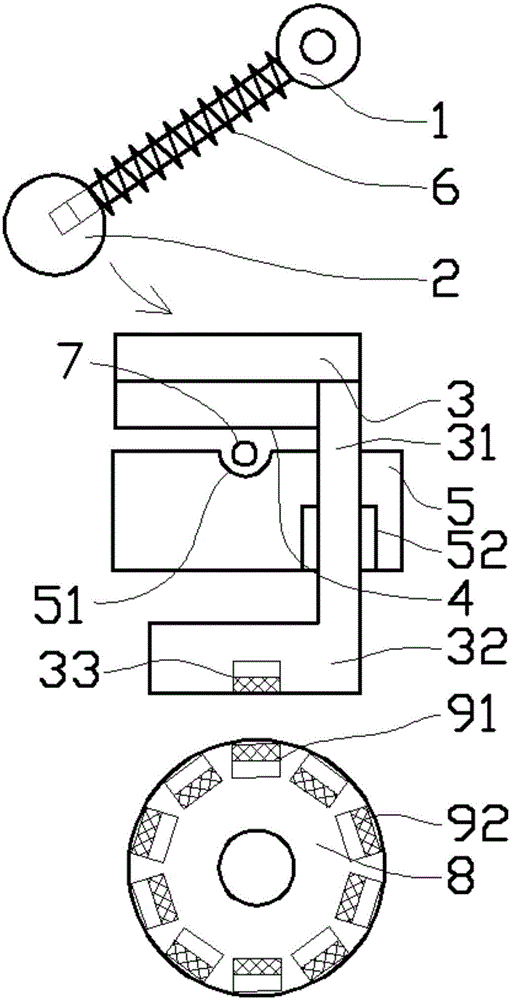

[0012] Such as figure 1 and figure 2 As shown in the embodiment, the impact type high-speed weft shearing device includes a rotating rod 1, a striking ball 2, a bumped block 3, an upper cutting head 4, and a lower cutting head 5; the rotating rod 1 is driven by The device is driven to rotate, the outer end of the rotating rod 1 penetrates into the impact ball 2, the impact ball 2 is connected to the inner side of the rotating rod 1 through the spring 6 sleeved on the rotating rod, and the impacted block 3 can be moved up and down Slidingly installed on the lower part of the rotating rod 1, with the rotation of the rotating rod 1, the impact ball 2 collides with the impacted block 3 periodically, and the upper shear head 4 is assembled on the impacted block 3 The lower part of the lower shearing cutter head 5 is fixedly assembled, and the weft thread 7 to be cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com