Halfen curtain wall embedded part installation device and Halfen curtain wall embedded part installation method

A technology of installation device and embedded parts, which is applied in the field of installation devices of HALFEN curtain wall embedded parts, can solve the problems of poor installation firmness and low positioning accuracy of curtain wall embedded parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

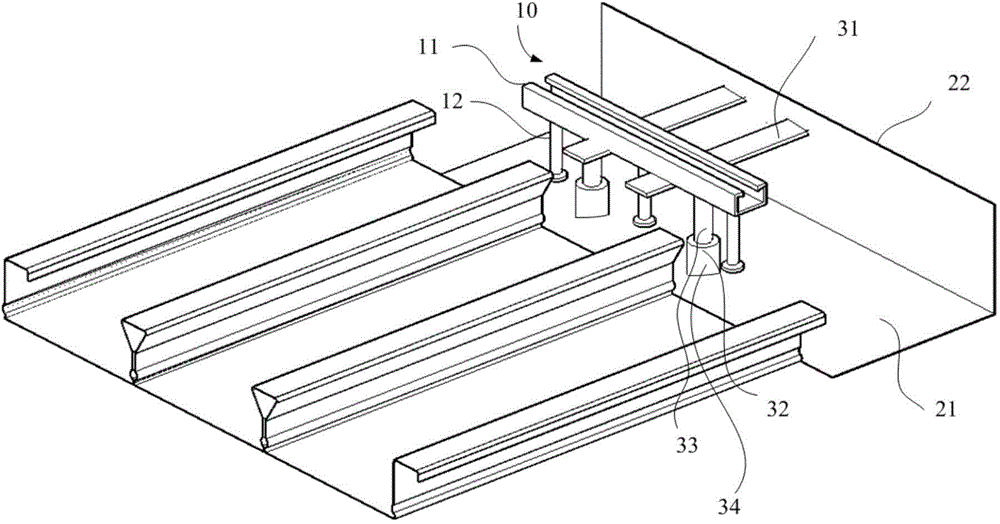

[0020] Combine below figure 1 The installation device of the HALFEN curtain wall embedded part of the present invention will be described in detail.

[0021] An installation device for a HALFEN curtain wall embedded part 10, which is suitable for positioning and installation of a HALFEN curtain wall embedded part. The HALFEN curtain wall embedded part 10 includes a HALFEN groove 11 and at least two anchors 12 fixedly arranged at the bottom of the HALFEN groove 11, The HALFEN curtain wall embedded part 10 is fixedly connected with the horizontal plate 21 of the L-shaped profiled steel plate through the anchor 12. The installation device of the HALFEN curtain wall embedded part 10 includes a fixing component 31 and an adjusting component 32. One end of the fixing component 31 is connected to the L-shaped profiled steel plate. The vertical plate 22 of the shaped steel plate is fixedly connected vertically, and the other end of the fixed component 31 is fixedly connected with the ...

Embodiment 2

[0027] Continue to combine figure 1 Describe in detail how to install HALFEN curtain wall using the installation device of HALFEN curtain wall embedded parts. The installation method of HALFEN curtain wall embedded parts includes the following steps:

[0028] Step 1: Provide the installation device of the HALFEN curtain wall embedded part 10 and the total station (not shown in the figure).

[0029] Specifically, first determine the predetermined installation position of the HALFEN curtain wall embedded part 10, connect the installation device with the HALFEN curtain wall embedded part 10 as a whole, and complete the installation and commissioning of the total station.

[0030] Step 2: use the total station to set out and position the two ends of the HALFEN groove 11 of the HALFEN curtain wall embedded part 10, and determine the predetermined installation height of the HALFEN groove 11.

[0031] continue to refer figure 1 According to the positioning of the total station, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com