Waste heat recovery type boiled drinking water electric heater

A technology of waste heat recovery and boiling water and electricity, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc. It can solve the problems of waste and not consider energy waste at the same time, and achieve the effect of reducing energy waste and meeting demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing:

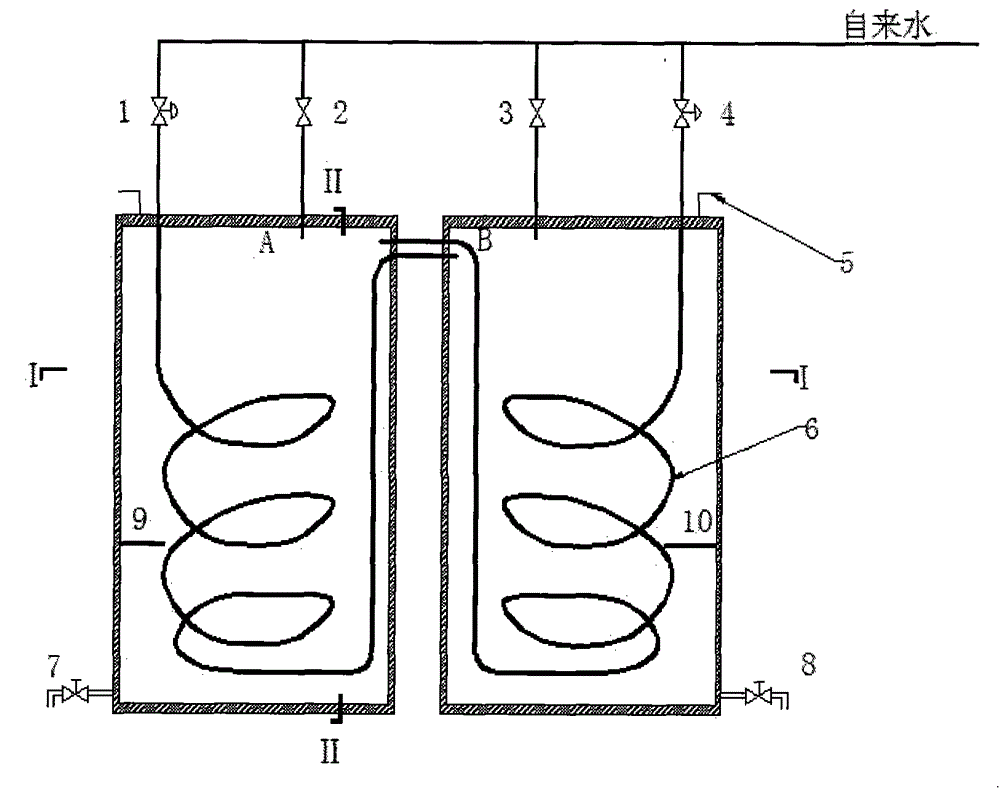

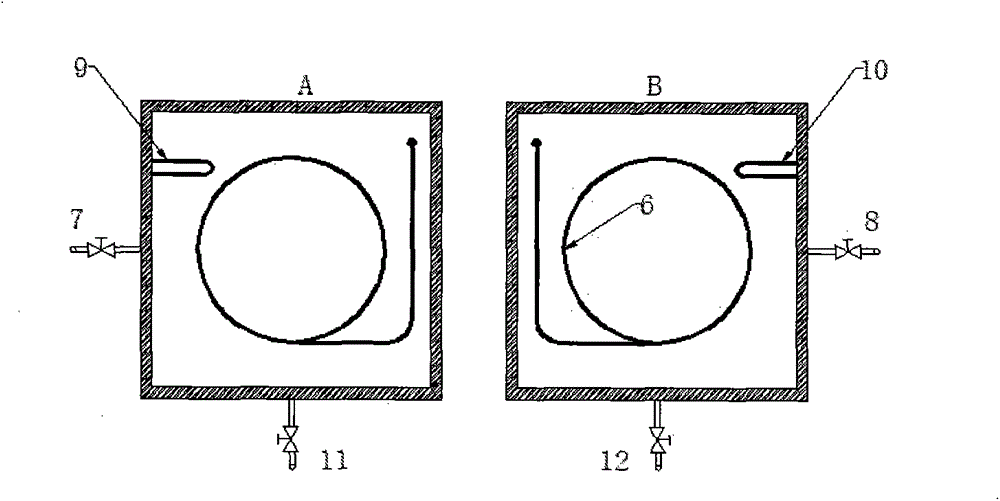

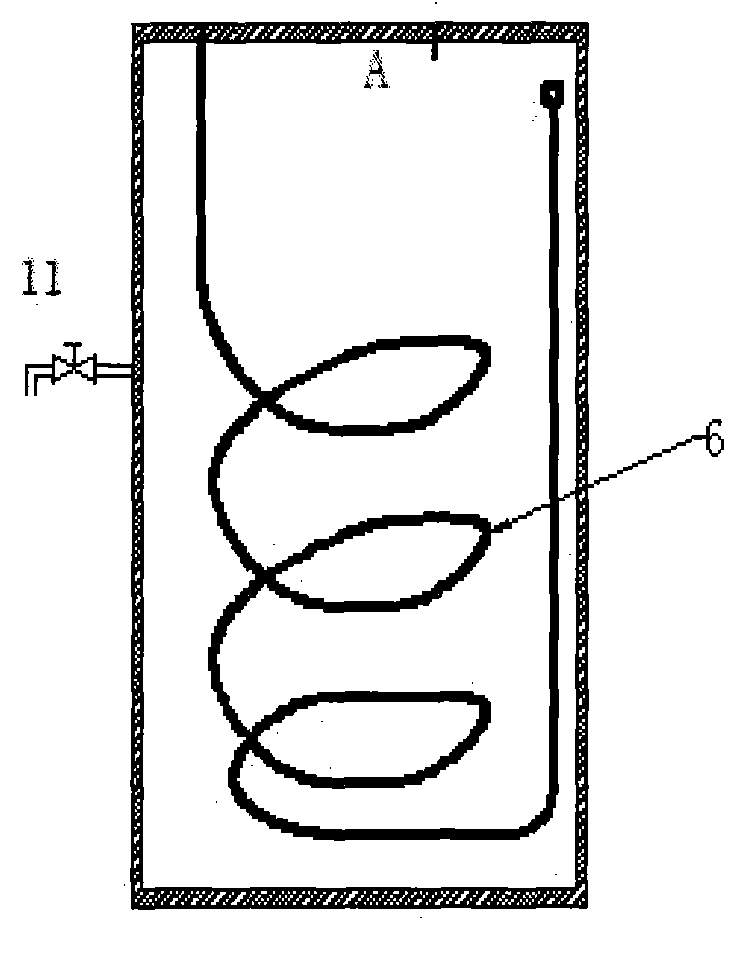

[0016] exist figure 1 Among them, the function of the valves (2) and (3) is to manually fill the container with water when the water heater is just started, and the main function of the electric valves (1) and (4) is to detect that the temperature in the corresponding container reaches 100 Just open when ℃, the running water that makes temperature lower enters spiral tube heat exchange device (6), and high temperature boiled water is cooled when running water is heated. The main function of the vent hole is to keep the pressure in the container constant, avoiding the difficulty of filling water caused by the pressure increase in the container during the water filling process. The structure of the spiral tube heat exchange device (6) increases the flow of tap water in the container on the one hand. Heat exchange time, on the other hand, the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com