A three-layer hollow glass body and its manufacturing method

A production method and technology for intermediate glass, applied in parallel glass structures and other directions, can solve the problems of poor adhesion and tightness of the three-layer glass body, poor thickness consistency, affecting product quality, etc., to achieve short drying and solidification time, product cost reduction, The effect of improving the bond tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

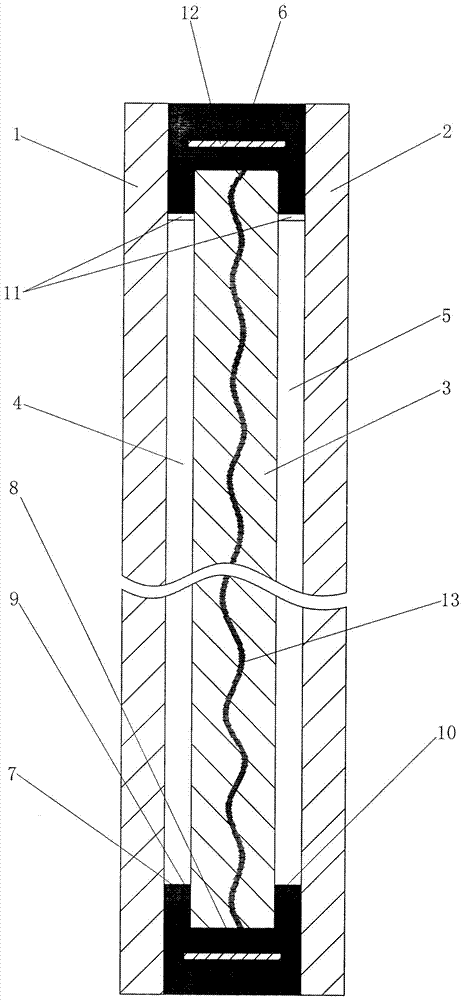

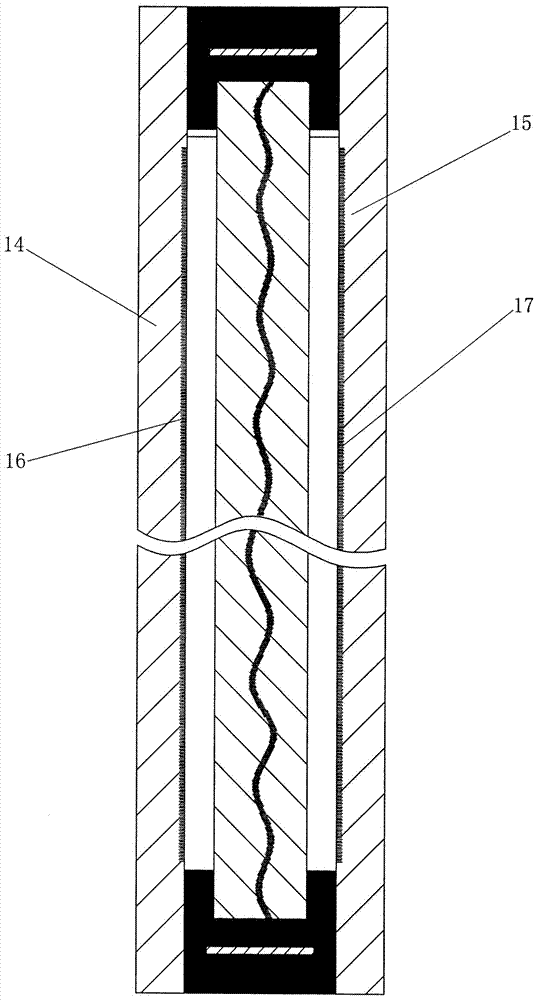

[0029] refer to figure 1, the main body of the three-layer insulating glass is composed of two outer glass layers 1, 2 that are laminated and bonded together by adhesives, and an intermediate glass layer 3 between the two outer glass layers 1, 2 A hollow cavity 4, 5 is formed between the two outer glass layers 1, 2 and the middle glass layer 3, and it is characterized in that: the thickness of the outer glass layers 1, 2 is 3-6 millimeters respectively, and the thickness of the middle glass layer 3 6-12 millimeters, the length and width of the middle glass layer 3 are respectively smaller than the length and width of the outer glass layer 10-12 millimeters, and the adhesive is a hot-melt adhesive strip ring 6 made of butyl hot-melt adhesive, The inner surface 7 of the hot-melt adhesive ring 6 is processed with an inlay groove 8 having a width equivalent to the thickness of the middle glass layer 3 at the middle position. Inlaid with the edge of the middle glass layer 3, the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com