Method for inversely calculating parameters of super-large-diameter shield tunnel segment joint

A shield tunnel segment and tunnel segment technology, which is applied in the field of inverse calculation of super large diameter shield tunnel segment joint parameters, can solve the problems of high cost and achieve the effect of avoiding test errors and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

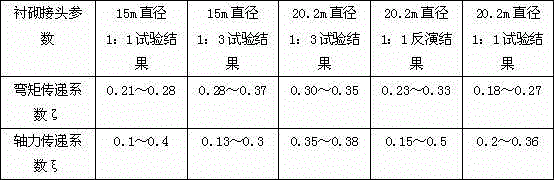

[0016] Embodiment: This embodiment specifically relates to a method for inversely calculating segment joint parameters of a super-large-diameter shield tunnel. By comparing the test results of the existing reduced-scale model and the full-scale model, the method obtains two different diameters. The correction coefficient of the tunnel segment joint mechanical parameters of the scale model is applied to the scaled-down test results of other super-large-diameter shield tunnels according to the linear relationship, and the corresponding super-large-diameter shield tunnel lining joint design parameters are inverted. The concrete steps of this method are as follows:

[0017] (1) Carry out the same kind of scale-down test of tunnel segments with two diameters (15m and 20.2m) at a ratio of 1:3. These two kinds of eccentric compression tests are routine tests in this field, so they will not be repeated here; Results The bending moment transfer coefficient ζ of the 15m diameter tunnel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com