Device for grading and detecting voltage of mobile phone batteries

A technology of detection device and mobile phone battery, applied in the direction of measurement device, sorting, measurement of electricity, etc., can solve problems such as short pause, battery surface wear, affecting detection efficiency, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

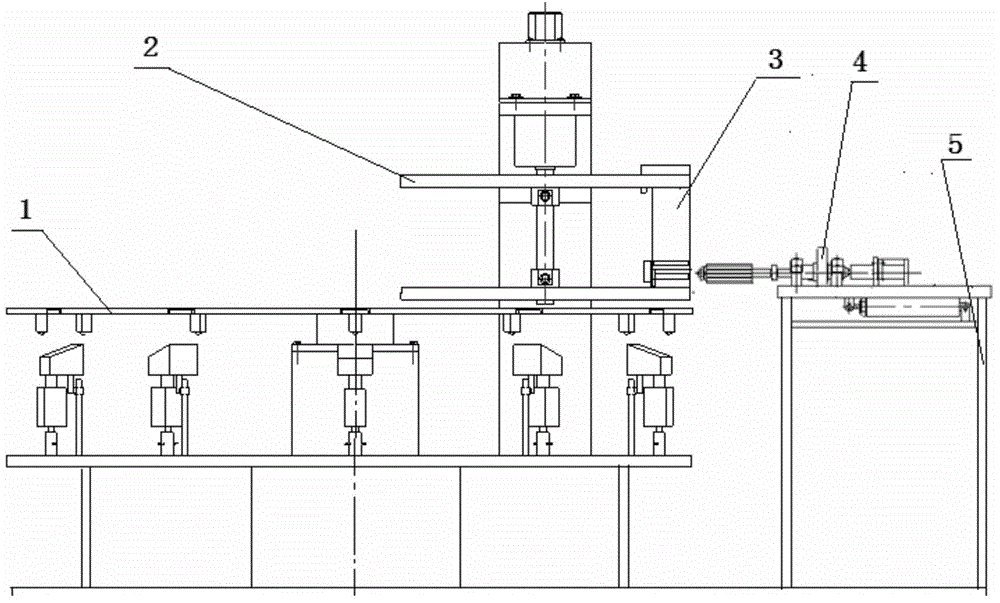

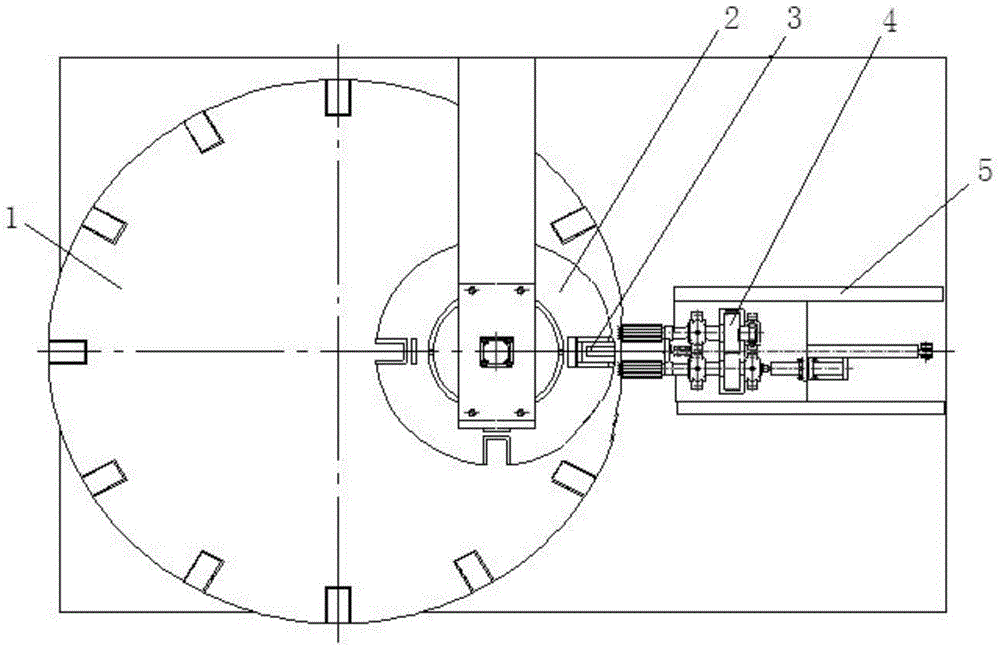

[0029] see figure 1 , figure 2 , the embodiment of the present invention includes a detection device and a sorting mechanism 1 . The detection device includes a detection turntable 2, a battery turnover box 3, a contact mechanism 4, and a slide rack 5; the detection device is installed in cooperation with the sorting mechanism 1, and coordinates actions to complete continuous detection and classification of mobile phone battery voltage.

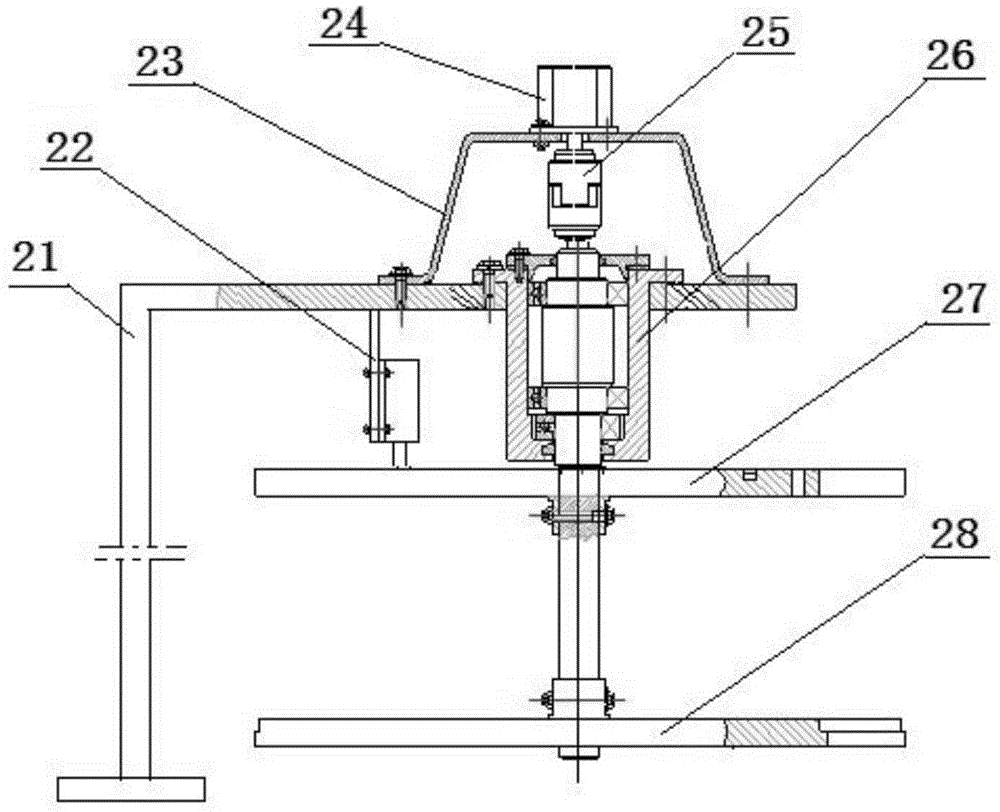

[0030] see image 3 , Figure 4, the detection turntable 2 is an assembly including a frame 21, an electromagnetic positioning device 22, a motor mount 23, a detection stepper motor 24, a detection shaft coupling 25, a detection spindle assembly 26, an upper detection disc 27, and a lower detection disc 28. Among them, the frame 21 is the installation carrier of the detection turntable 2, the detection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com