Adjustable rapid clamp

An adjustable and fast technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of reducing clamping efficiency, unable to realize self-locking and pressing parts, etc., to improve clamping efficiency, avoid adjustment, and prevent falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

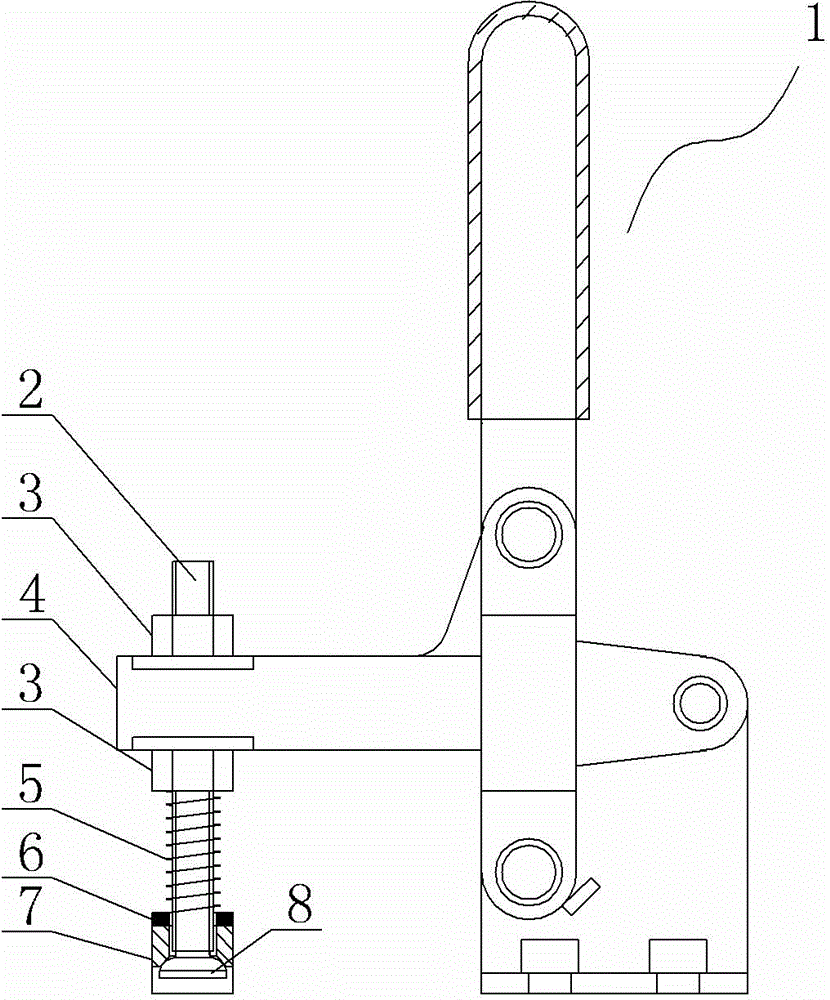

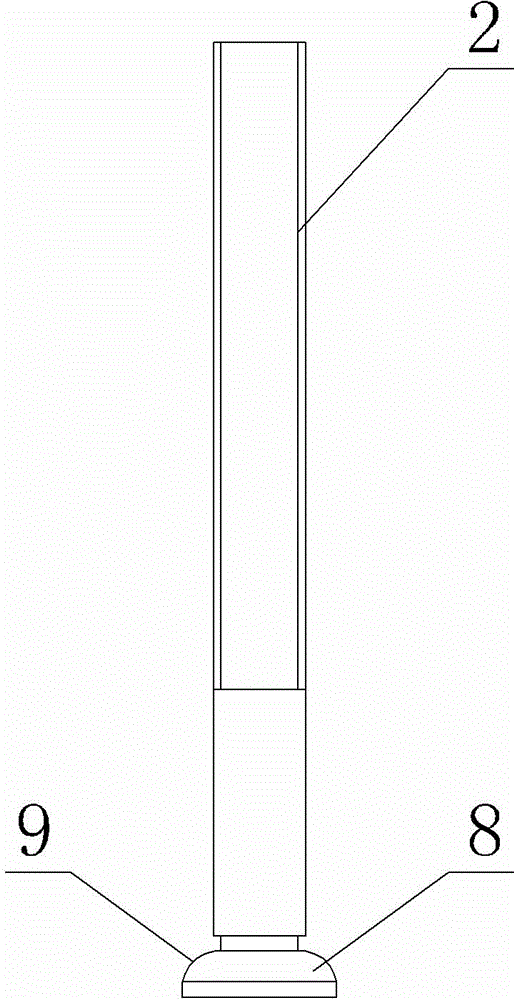

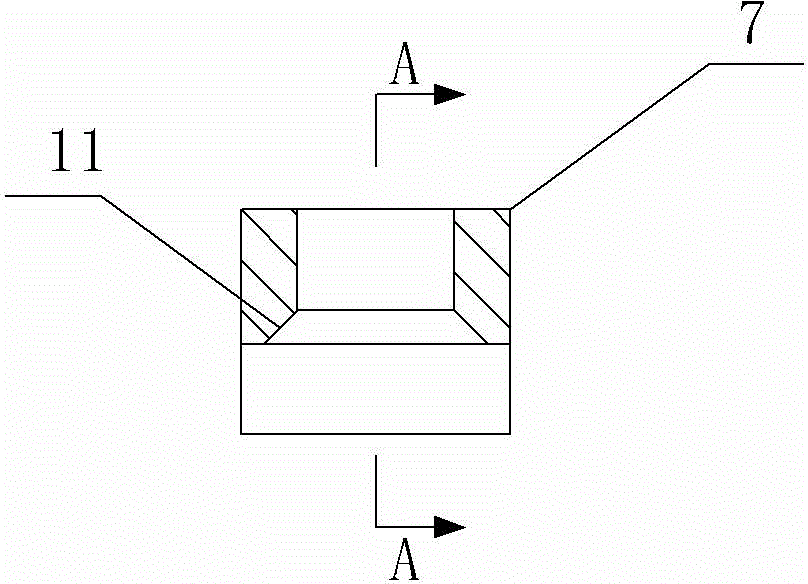

[0016] Such as Figure 1 to Figure 4 As shown, the adjustable quick clamp, the end of the rocker 4 of the quick clamp 1 is provided with a pressure piece, the pressure piece includes a screw 2, the screw 2 is installed on the end of the rocker 4 of the quick clamp, and the screw 2 passes through two nuts 3 Locked on the end of the rocker 4 of the quick clip, the screw 2 is slidingly connected with the pressure head 7, the root of the screw 2 is fixed with a limit block 8, and the bottom end of the perforation that the pressure head 7 is slidingly connected with the screw 2 is provided with a limit Groove 11, the top of pressure head 7 is provided with washer 6, is positioned at the top of pressure head 7, and screw rod 2 is covered with compression spring 5, and compression spring 5 top-mounts the lower end surface of nut 3 and the upper end surface of washer 6 respectively, and makes the limit groove 11 Clamp the limit block 8, the cross section of the limit groove 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com